A sand screening device

A screening device, sand and gravel technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of low work efficiency, incomplete sand and gravel screening, difficult to ensure the quality of power construction, etc., to achieve screening efficiency High, easy to collect and transport effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

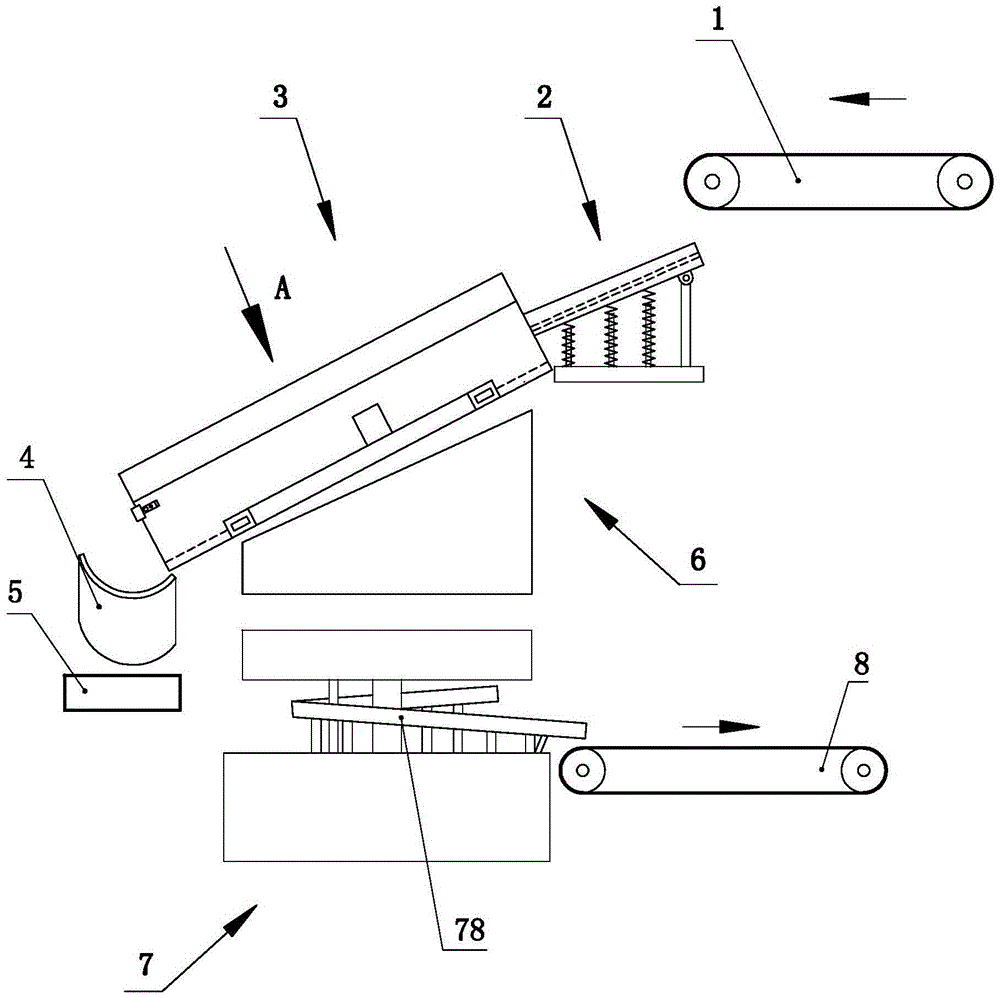

[0032] Such as Figure 1 to Figure 14 As shown, the present invention includes a first conveyor 1, a buffer assembly 2, a primary screening assembly 3, a guide plate 4, a second conveyor 5, a distribution assembly 6, a secondary screening assembly 7 and a third Conveyor 8, the present invention is described below in conjunction with accompanying drawing.

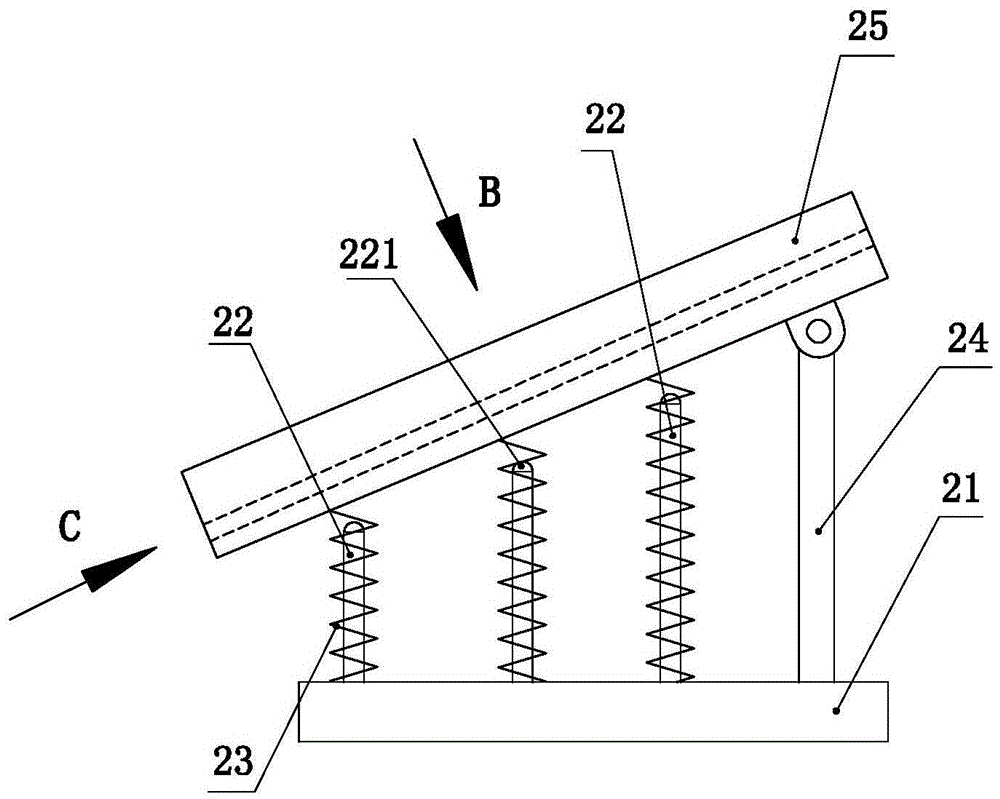

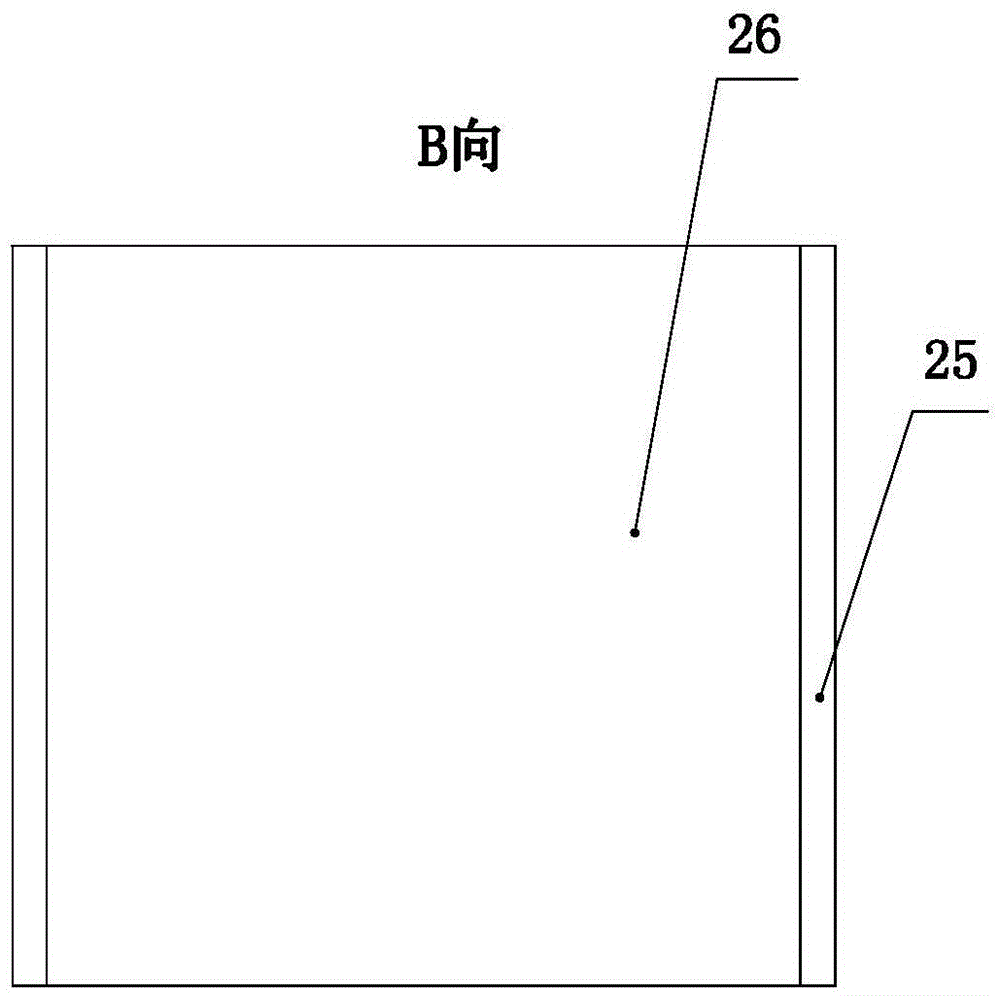

[0033] Such as figure 1 As shown, the sand to be screened is provided on the first conveyor 1, and the first conveyor is used for transporting the sand to be screened. There is a buffer assembly 2 at the end of the first conveyor, such as figure 2 As shown, the buffer assembly includes a first frame 21, a column 22, a first spring 23, a pole 24, a swash plate 25 and a rubber pad 26, the first frame is the base of the buffer assembly, and the first frame is used for Install other components. Several vertical columns 22 are arranged on the top of the first frame, and the lengths of the columns increase successively from l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com