Special 360° steering sleeve device and method of use for overhead cable live peeling

An overhead cable and steering sleeve technology, which is used in cable installation devices, cable installation, equipment for dismantling/armored cables, etc. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

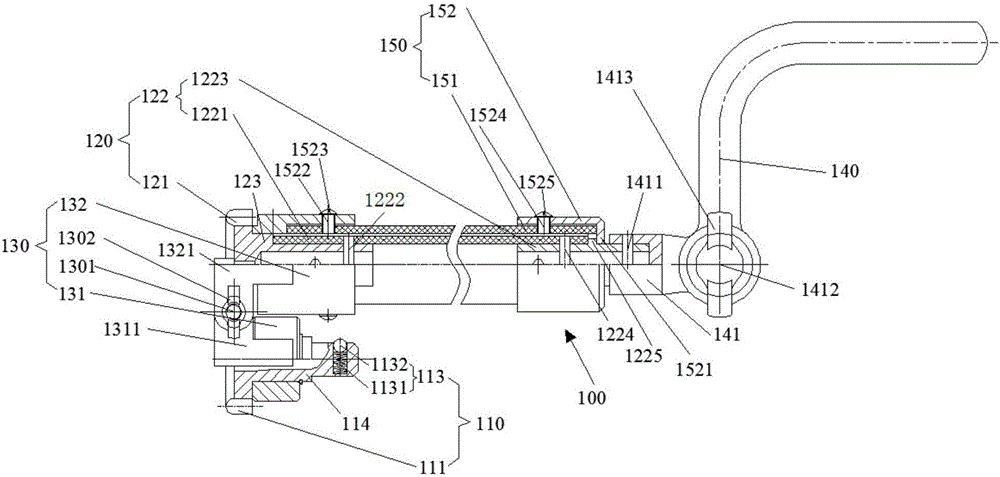

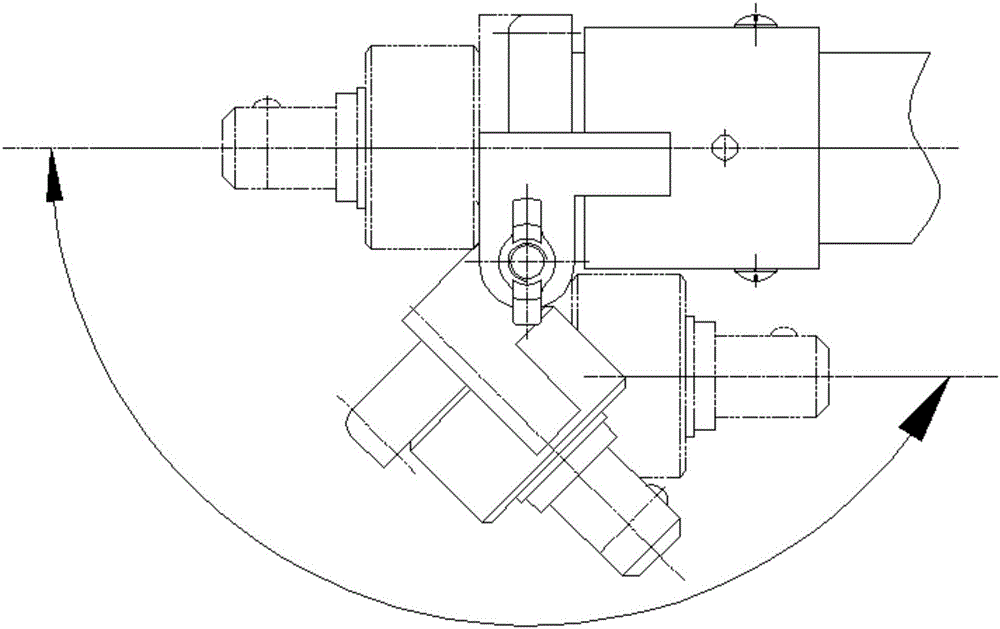

[0035] refer to figure 1 , figure 1 A special 360° steering sleeve device 100 for live peeling of aerial cables according to an embodiment of the present invention is shown. The sleeve device 100 includes a sleeve head (not shown in the figure), a sleeve head drive mechanism 110 for fixing the sleeve head and driving the sleeve head to rotate, and a sleeve head drive mechanism 110 reversibly installed on the sleeve head. The mechanism 110 is used to drive the sleeve head drive mechanism 110 to rotate, thereby driving the transmission mechanism 120 for the sleeve head to rotate.

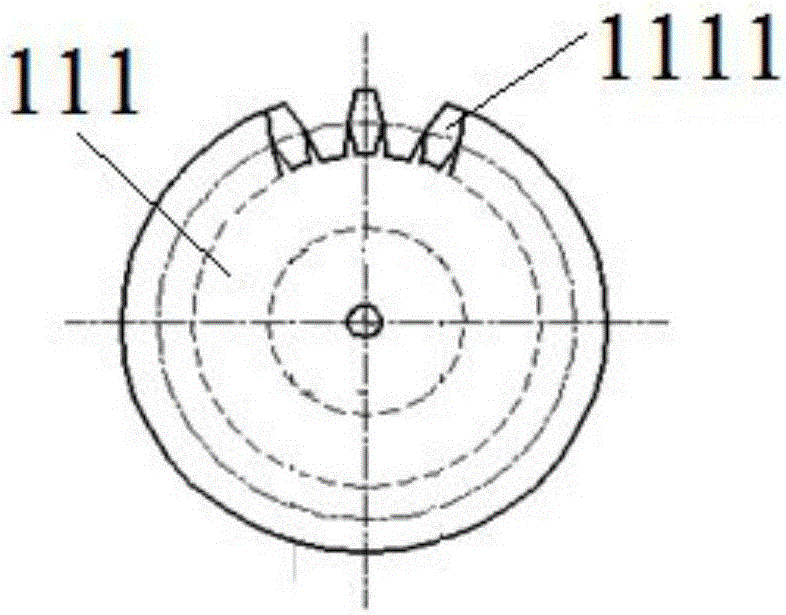

[0036] Further, in this embodiment, refer to figure 1 , The socket head driving mechanism 110 includes a driven gear 111 and a fixing device 113 . The driven gear 111 is axially formed with a driven shaft 114 . Here, the driven shaft 114 may be integrally formed with the driven gear 111 , or fixedly installed on the driven gear 111 by screws or pins.

[0037] Further, the fixing device 113 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com