Preparation method and product of double-density-layer middle sole

A dual-density, lower-layer technology, applied in shoe soles, footwear, clothing, etc., can solve problems such as inability to meet consumers, achieve the effect of improving work efficiency and product quality, avoiding the use of glue, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended purpose, the specific implementation modes of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

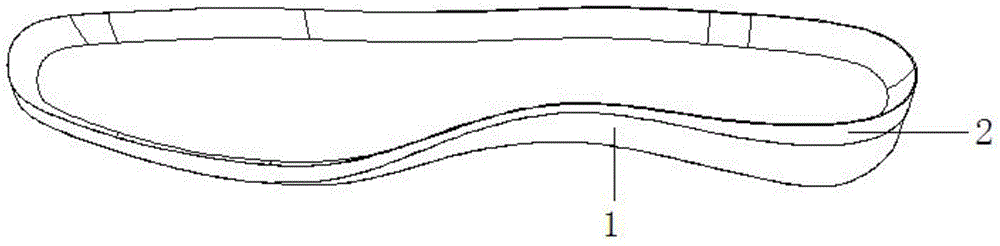

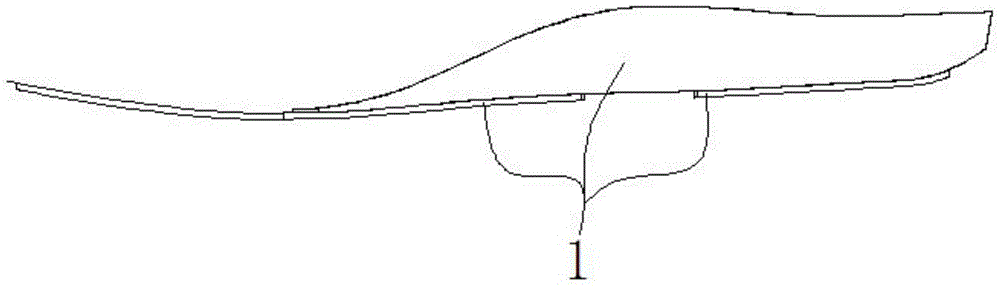

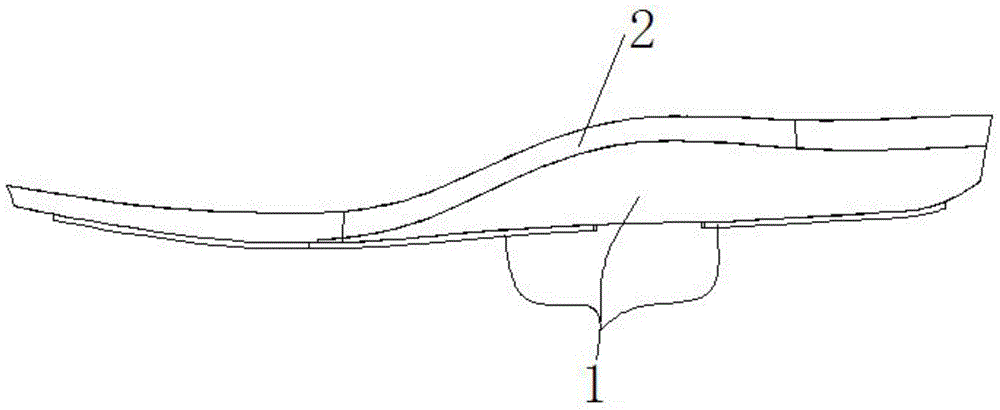

[0028] Please refer to figure 1 , figure 2 and image 3 , the preparation method of the double-density layer shoe midsole provided by the present embodiment, wherein, comprises the following steps:

[0029] 1) Prepare a hard material mold and a soft material mold, the hard material mold is provided with grooves corresponding to the predetermined thickness of the lower layer 1, and the soft material mold is provided with grooves corresponding to the predetermined thickness of the lower layer 1 and the upper layer 2. and corresponding grooves;

[0030] 2) Start the injection molding machine, and under the conditions of temperature 200-220°C and pressure 80-100KG, inject a ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap