Composite-material vertical fin combination method of unmanned aerial vehicle

A vertical stabilizer and composite material technology, which is applied in the field of UAV composite vertical stabilizer combination, can solve the problems of poor assembly accuracy, large number of parts, complex mold modules, etc., to achieve simple mold, improve assembly accuracy, and reduce the number of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

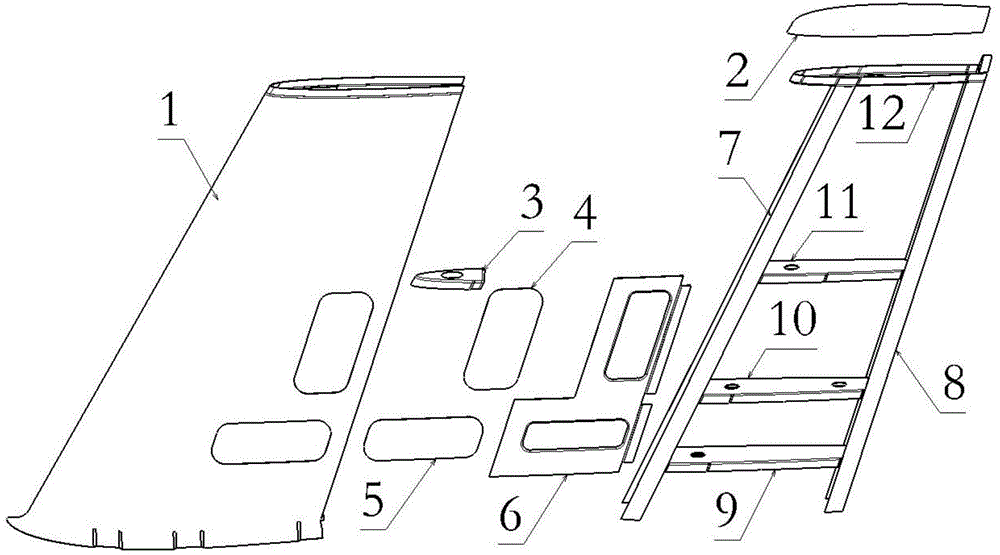

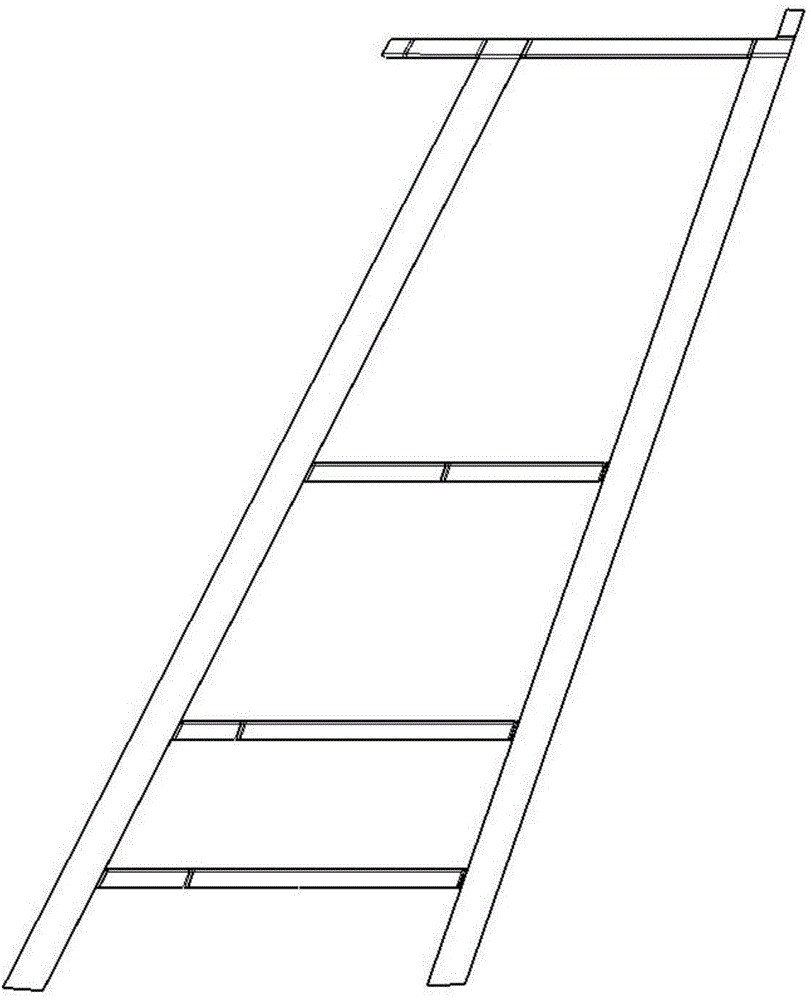

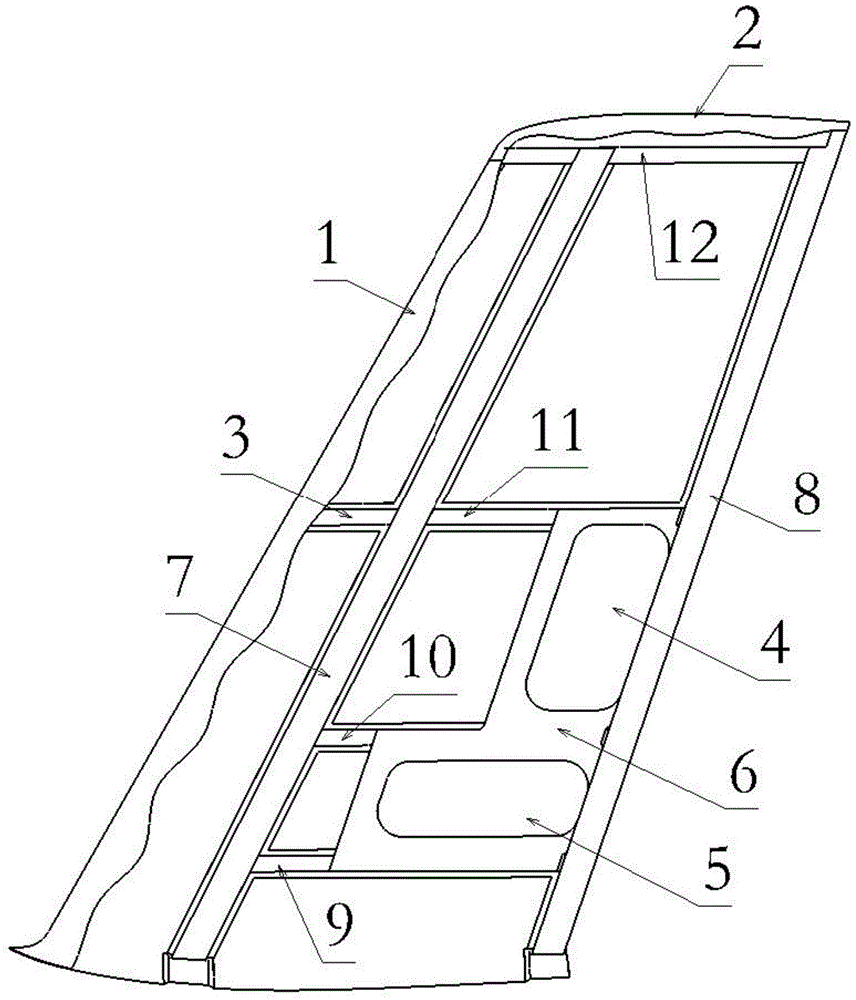

[0018] A certain type of UAV vertical stabilizer such as image 3 As shown, lay out the front and rear beams on the mould, then lay 1# ribs, 2# ribs, 3# ribs, and 4# ribs on the silicone rubber core and fix them on the mold with tooling clamps. 3233 / CF3011 / 52 bidirectional carbon fiber prepreg cloth is added to the surface on the side where the rear inner surface is in contact with the front and rear beams as a continuous layer, and after vacuuming, it enters the autoclave and co-cures to form a vertical stabilizer skeleton, such as figure 2 As shown, the curing temperature is 125±5°C, and the temperature is kept for 1.5 to 2 hours. Then, the frame of the vertical stabilizer and the leading edge rib, the reinforcement frame of the cover, and the skin glue-riveting are formed, and the connection between the skin and the frame is strengthened with 3233 / CF3011 / 52 bidirectional carbon fiber prepreg cloth. Because of the wingtip cover, 1 The # and 2# covers need to be dismantled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com