Feeding roller of graphite calendaring machine

A calender and graphite technology, applied in the direction of rollers, conveyor objects, transportation and packaging, etc., can solve problems such as affecting the production of graphite products, and the feeding device cannot operate normally, so as to ensure normal rotation, ensure sufficient lubrication, and ensure normal operation. The effect of running

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

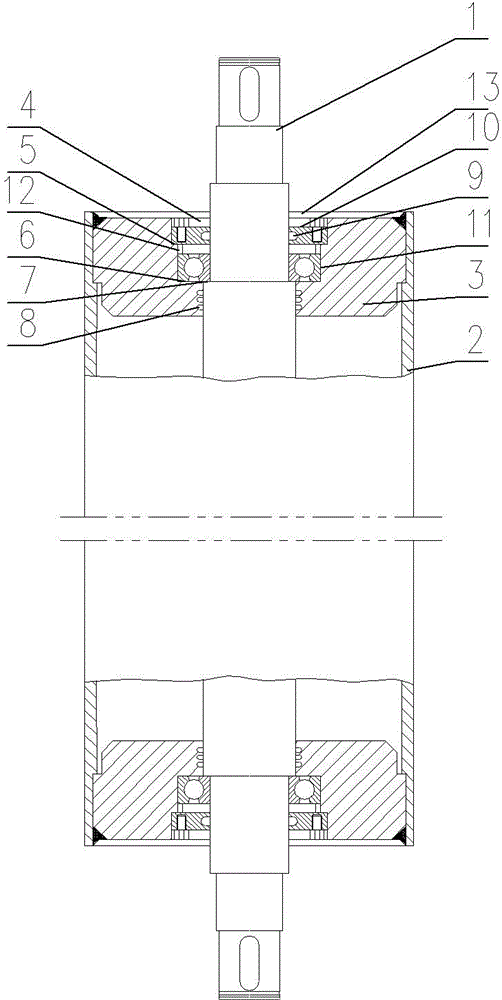

[0013] Such as figure 1 As shown, the feeding roller of the graphite calender includes a cylinder body 2 and a central axis 1. The two ends of the cylinder body 2 are equipped with a head 3, and the lower end of the head 3 is against the stepped surface inside the cylinder body. The upper end is welded to the cylinder, the head 3 has a stepped perforation 4 in the axial direction, the lower step surface 6 of the perforation 4 is installed with a bearing 11, the central axis 1 passes through the head 3 in the axial direction of the cylinder 2, and the center The two ends of the shaft 1 are fitted with the bearings 11 respectively. A cover plate 10 is installed on the upper step surface 5 of the perforation 4. The cover plate 10 has a through hole in the axial direction for the central shaft 1 to pass through. A set of Seal ring 1 9, three sets of seal ring 2 8 are embedded in the lower part of the perforation 4, and the pressure ring 12 on the lower end surface of the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com