Sectional rolling body type ringless bearing structure

A rolling structure and rolling element technology, applied in the direction of roller bearings, ball bearings, bearing components, etc., can solve the problems of mechanical parts wear, wear, and large wear, and achieve improved rolling structure, reduced wear, and strong wear resistance and adaptive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

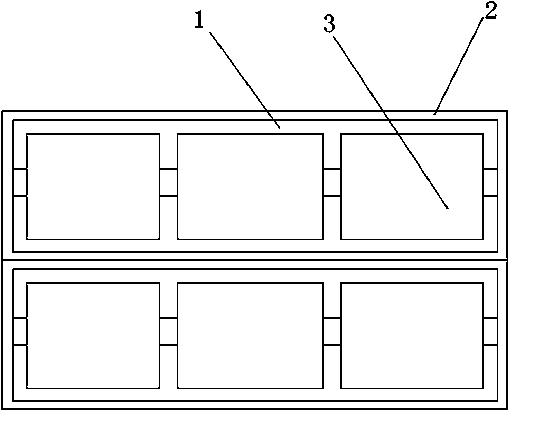

[0021] As shown in the figure, a segmented rolling element type ringless bearing structure includes a cage 2 with several continuous needle grooves 1, and rolling elements installed in the needle grooves 1. The rolling elements are composed of several connected rolling elements. The structure 3 is composed; several rolling structures 3 are connected side by side.

[0022] The rolling structure 3 is a needle roller.

[0023] The rolling structure 3 is a rolling ball.

[0024] The rolling body is composed of 3-5 rolling structures 3 .

[0025] The distance between two adjacent rolling structures 3 is 0.1mm-0.3mm.

[0026] In the segmented rolling element type ringless bearing structure of the present invention, needle rollers or rolling balls are selected according to the actual working environment. Needle rollers can be used whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com