Anti-twisting device for paying off steel strands

An anti-tangle and steel strand technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material handling, etc., can solve problems affecting construction progress, steel strand winding and crossing, low construction efficiency, etc., and achieve improvement efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

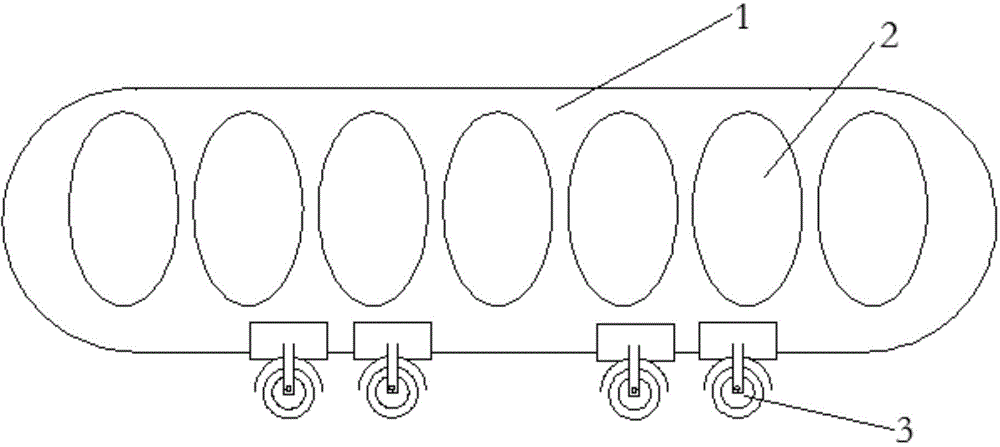

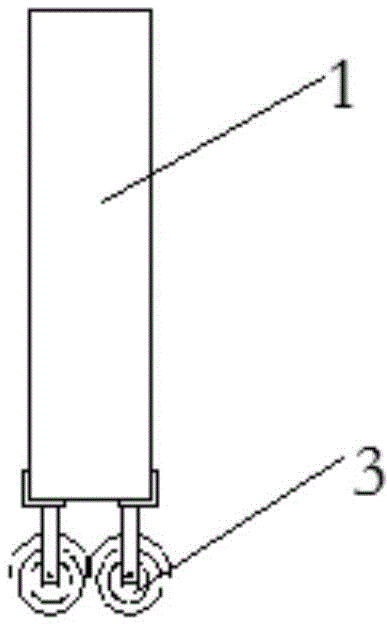

[0012] Such as figure 1 and figure 2 As shown, the present invention comprises a strip plank 1, and the strip plank 1 is placed sideways, and the bottom of the strip plank 1 is provided with four groups of universal wheels 3, and each group is arranged side by side by two universal wheels, and the length Several through holes 2 are evenly distributed on the side of the strip plank 1 . The through hole 2 is preferably in the shape of an ellipse whose long axis is in the radial direction. During the unwinding process of the steel strands, a plurality of steel strands are inserted one by one into the elliptical through hole 2 created by the present invention to prevent the steel strands from being placed long and often crossing, and the anti-winding device The universal wheel 3 can move along with the dragging of the steel strand, and can ensure the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com