A biomedical multi-component copolymerization cross-linked polyester elastomer material and preparation method thereof

An elastomer material, multi-component copolymerization technology, applied in the field of biomedical multi-component copolymerization cross-linked polyester elastomer material and its preparation, to achieve the effects of good mechanical strength and high elasticity, good biocompatibility, and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A biomedical multi-component copolymerized cross-linked polyester elastomer material, the preparation method of which is:

[0036] (1) Add 1.6 mol of dehydrated L-lactic acid, 0.05 mol of dehydrated polyethylene glycol-600 and 0.15 mol of sebacic acid into a single-necked flask and mix them, and stir for 1 hour at 120°C under nitrogen protection until the sebacic acid is completely Dissolve, the system forms a clear and transparent liquid;

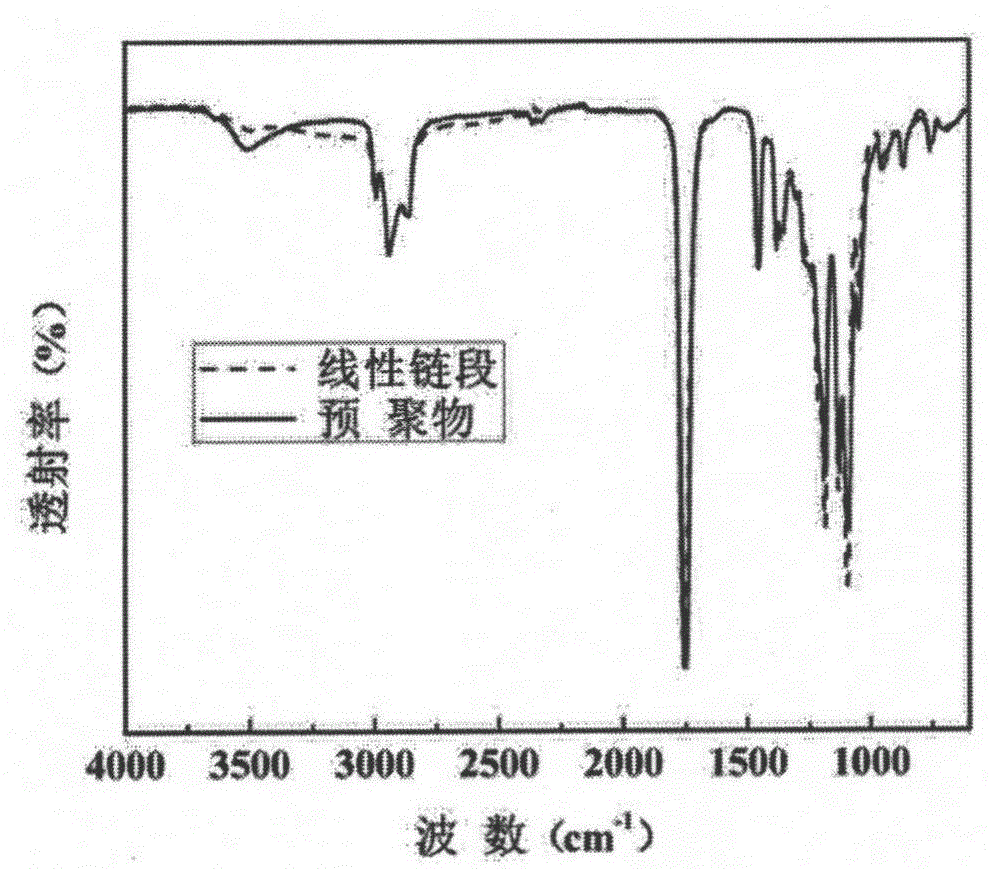

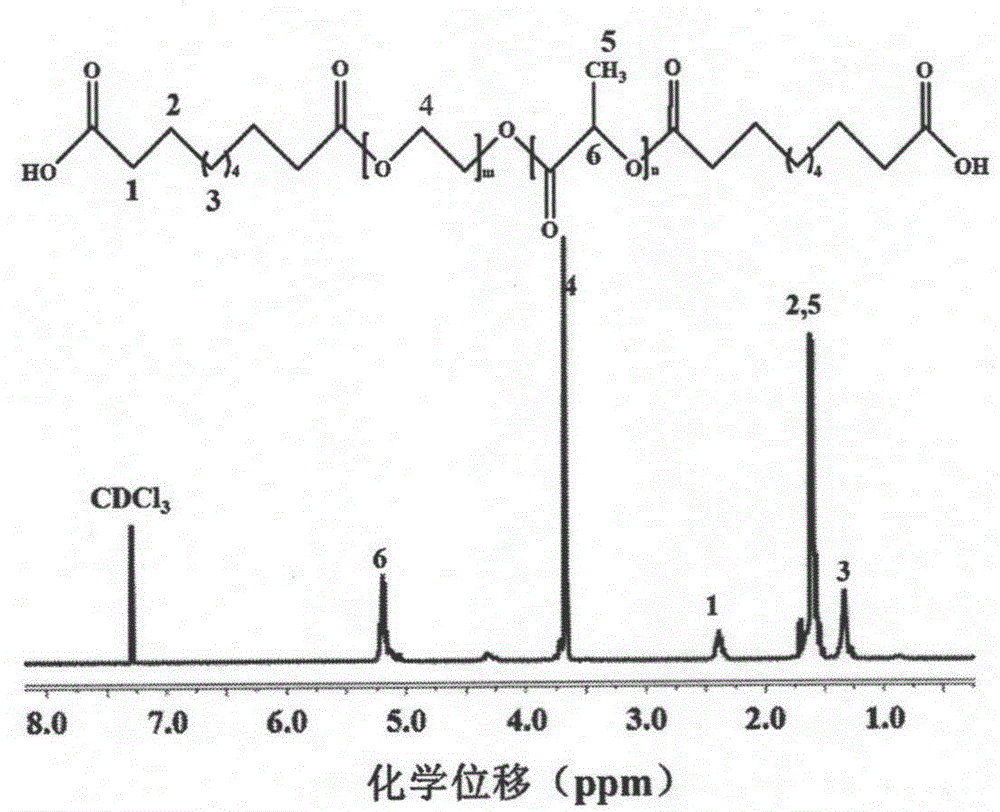

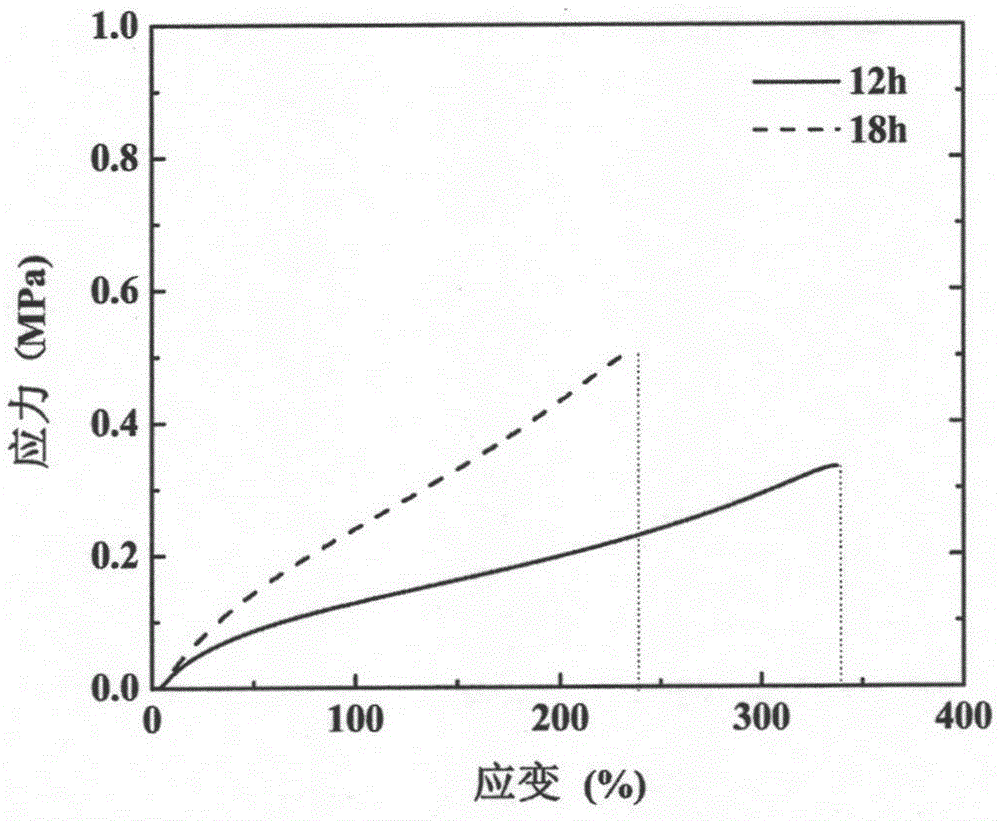

[0037] (2) Add 0.0017 mol of stannous octoate and 0.0017 mol of p-toluenesulfonic acid into the reaction system, keep the pressure of the reaction system at 3325 Pa, slowly increase the reaction temperature from 120°C to 180°C within 8 hours, and keep the temperature at 180°C React for 8 hours; then slowly reduce the pressure to 1.3 Pa, keep the temperature at 180°C, and react for 6 hours to obtain a linear segment with carboxyl groups at both ends formed by random copolymerization of lactic acid, polyethylene glycol-600, and sebaci...

Embodiment 2

[0042] A biomedical multi-component copolymerized cross-linked polyester elastomer material, the preparation method of which is:

[0043] (1) Add 1.2 mol of dehydrated L-lactic acid, 0.05 mol of dehydrated polyethylene glycol-600 and 0.15 mol of sebacic acid into a single-necked flask and mix them, and stir for 1 hour at 120°C under the protection of nitrogen until the concentration of sebacic acid Completely dissolved, the system forms a clear and transparent liquid;

[0044](2) Add 0.0013 mol of stannous octoate and 0.0013 mol of p-toluenesulfonic acid into the reaction system, keep the pressure of the reaction system at 3325 Pa, slowly increase the reaction temperature from 120°C to 180°C within 8 hours, and keep the temperature at 180°C React for 8 hours; then slowly reduce the pressure to 1.3 Pa, keep the temperature at 180°C, and react for 6 hours to obtain a linear segment with carboxyl groups at both ends formed by random copolymerization of lactic acid, polyethylene g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com