Expander rolls for textile machinery

A technology of textile machinery and expanding rollers, applied in textiles and papermaking, fabric elongation, fabric surface trimming, etc., can solve problems such as small expansion angle, unmaintainable, easy-wearing fabrics, etc., to achieve less damage and flexibility Design, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

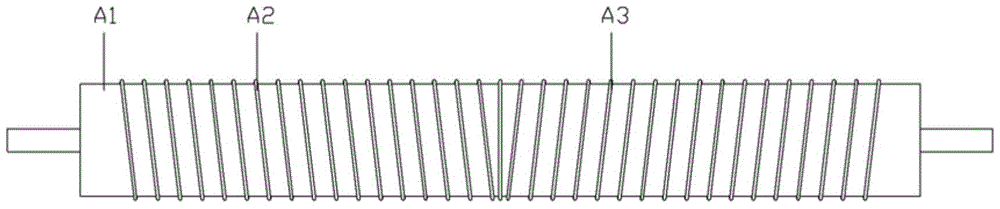

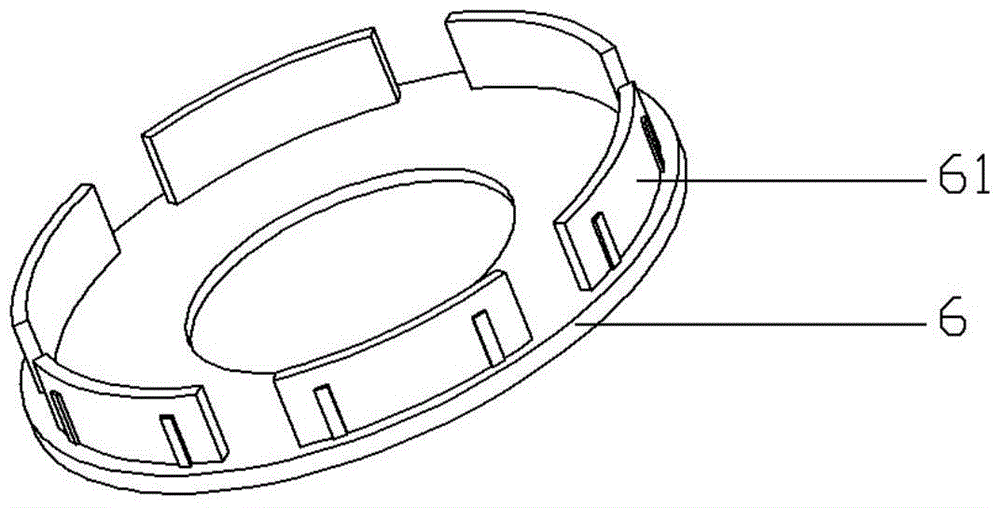

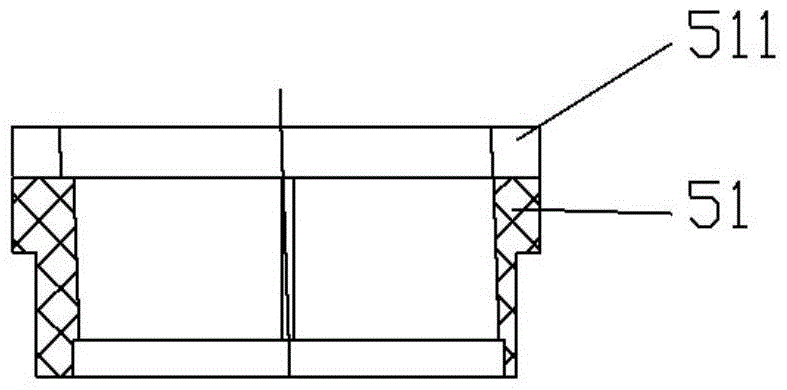

[0032] Example: see Figures 2 to 10 As shown, the expanding roller for textile machinery includes a round tube 1, the inner ring of the deep groove ball bearing 2 is fixed in the middle of the round tube 1, and the expanding unit 5 is composed of a plastic washer 51, an aluminum wheel frame 52, and a cylindrical roller bearing 53. Composed of circlip 54, plastic washer 51 is inserted into the aluminum wheel frame 52, the inner ring of cylindrical roller bearing 53 is bonded and fixed with plastic washer 51, and the upper end surface of the outer ring of cylindrical roller bearing 53 is placed on the aluminum wheel frame On the step 521 of the center hole of the aluminum wheel frame of the frame 52, the clip spring 54 is clamped in the aluminum wheel frame slot 522 on the inner wall of the center hole of the aluminum wheel frame 52, and the clip spring 54 is pressed against the outer ring of the cylindrical roller bearing 53. The outer surface of the wheel frame 52 is covered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com