A full-frequency sound absorption and noise reduction device

A sound absorption and noise reduction technology, applied in noise absorption devices, buildings, etc., can solve problems such as human health hazards, narrow sound absorption frequency band, poor sound absorption performance, etc., to save costs, increase sound absorption frequency band, improve The effect of sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

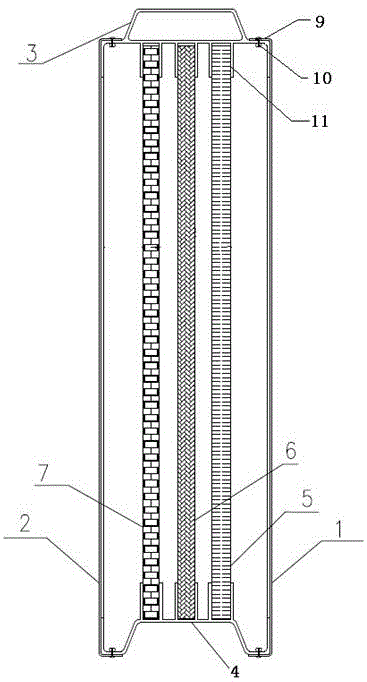

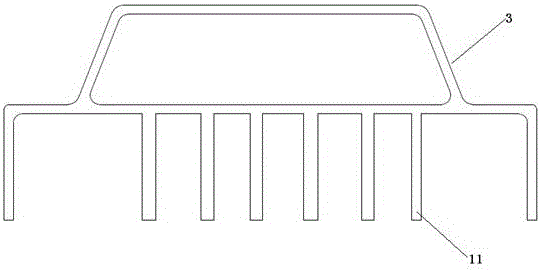

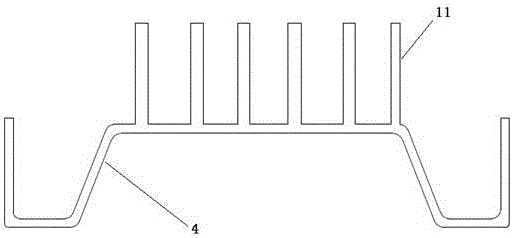

[0029] Such as Figure 1-4 As shown, a full-frequency sound absorption and noise reduction device includes a panel 1, a sound-absorbing material layer, a back plate 2, a cover plate 3, a bottom plate 4 and two side plates 8, the panel 1, the back plate 2, the cover plate 1. The bottom plate 4 and two side plates 8 form a cavity structure, and the sound-absorbing material layer is arranged inside the cavity structure. The sound-absorbing material layer is foamed rubber 5, foamed ceramics 6 and foamed aluminum 7; the panel 1 is evenly stamped Sound-absorbing hole, back plate 2 pressing edge; cover plate 1 lower surface is provided with 3 card slots 11, bottom plate 4 upper surface is provided with 3 card slots 11 matching with cover plate 1; from panel 1 to back plate 2, The foamed rubber 5, the foamed ceramics 6, and the foamed aluminum 7 are arranged between the cover plate 1 and the bottom plate 4 in turn, and the upper and lower ends are correspondingly arranged in the slots...

Embodiment 2

[0031] It is basically the same as Example 1, except that the sound-absorbing materials installed from panel 1 to back panel 2 are foam ceramics 6, foam aluminum 7, and foam rubber 5; the thickness of foam rubber 5 is 40 mm, and the thickness of foam ceramics The thickness of 6 is 30mm, the thickness of aluminum foam 7 is 5mm; the distance between panel 1 and ceramic foam 6 is 20mm, the distance between ceramic foam 6 and aluminum foam 7 is 10mm, and the distance between aluminum foam 7 and foam rubber The cavity distance formed by 5 is 10 mm, and the cavity distance formed by the foam rubber 5 and the back plate 2 is 30 mm. With this device, the measured sound absorption coefficient is 0.81, the bending load resistance is increased by 30%, the wind pressure resistance performance ratio is increased by 20%, and the service life is nearly doubled.

Embodiment 3

[0033] It is basically the same as Example 1, except that the sound-absorbing materials installed from panel 1 to back panel 2 are aluminum foam 7, foam rubber 5, and ceramic foam 6; the thickness of foam rubber 5 is 60 mm, and the foam The thickness of the ceramic 6 is 50mm, the thickness of the foamed aluminum 7 is 15mm; the distance between the panel 1 and the foamed aluminum 7 is 25mm, the distance between the foamed aluminum 7 and the foamed rubber 5 is 30mm, the foamed ceramic 6 and the foamed The distance between the cavity formed by the aluminum 7 is 30 mm, and the distance between the cavity formed by the foamed aluminum 7 and the back plate 2 is 35 mm. With this device, the measured sound absorption coefficient is 0.86, the noise reduction is increased by 20%, the bending load is increased by 30%, the wind pressure resistance performance is increased by 20%, and the service life is nearly doubled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com