Method and structure for fixedly sealing seam between infill wall and beam or board

A technology for filling walls and beams and slabs, which is applied in the direction of building construction and construction to achieve the effect of improving sound insulation performance and easily shrinking excessively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

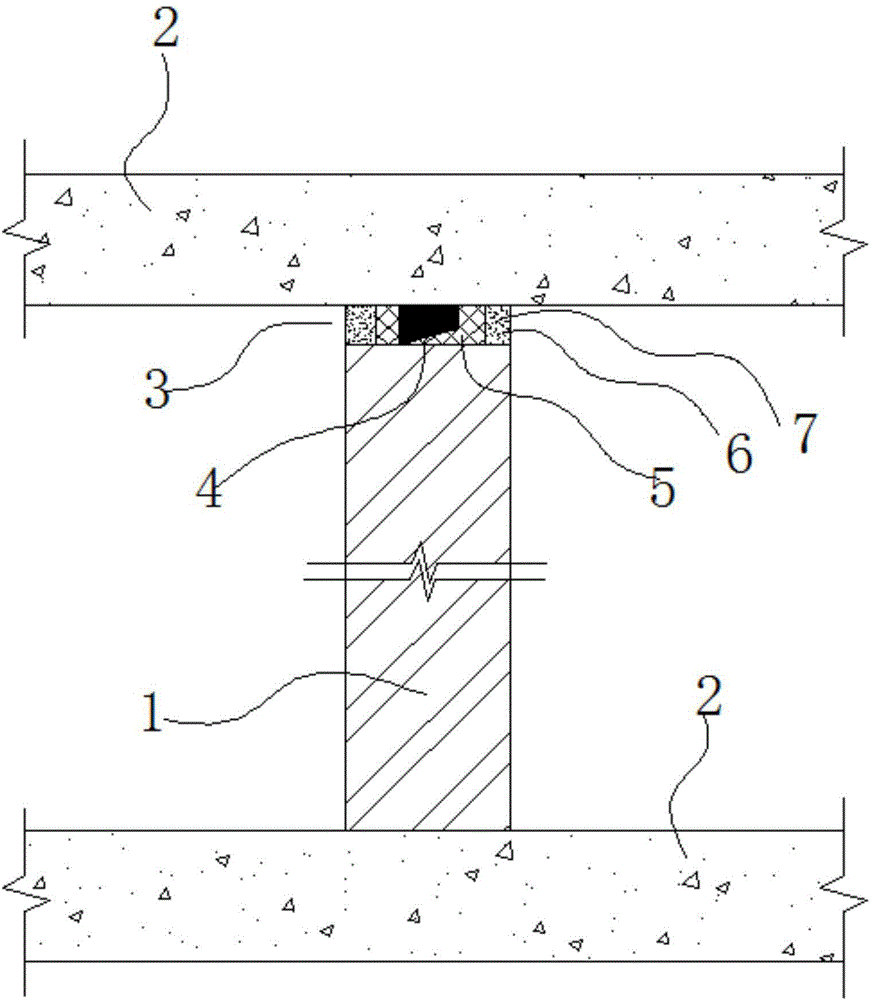

[0028] see figure 1 A method for sealing the joint between the filled wall and the beam slab provided in this embodiment includes the following steps:

[0029] 1) In advance, drive the jacking fixture 4 into the seam 3 between the top of the infill wall 1 and the beam or slab (beam slab 2), and fix the position between the infill wall 1 and the beam or slab to constrain the filling Displacement of the wall; wherein, the top member 4 is a wedge-shaped stone, wood or brick, and one is set at every 100-300mm interval along the 3 joints.

[0030] 2) Insert filler 5 at the mid-span position of splicing seam 3, and reserve grooves 6 on both sides of splicing seam 3; wherein, said filler 5 is a compressible solid material, and said compressible The solid material is PU foam caulk.

[0031] 3) Fill the grooves 6 on both sides of the splicing joint 3 tightly with mortar 7; wherein, the mortar 7 is a building mortar that has water retention and does not need to be used for moisturizin...

Embodiment 2

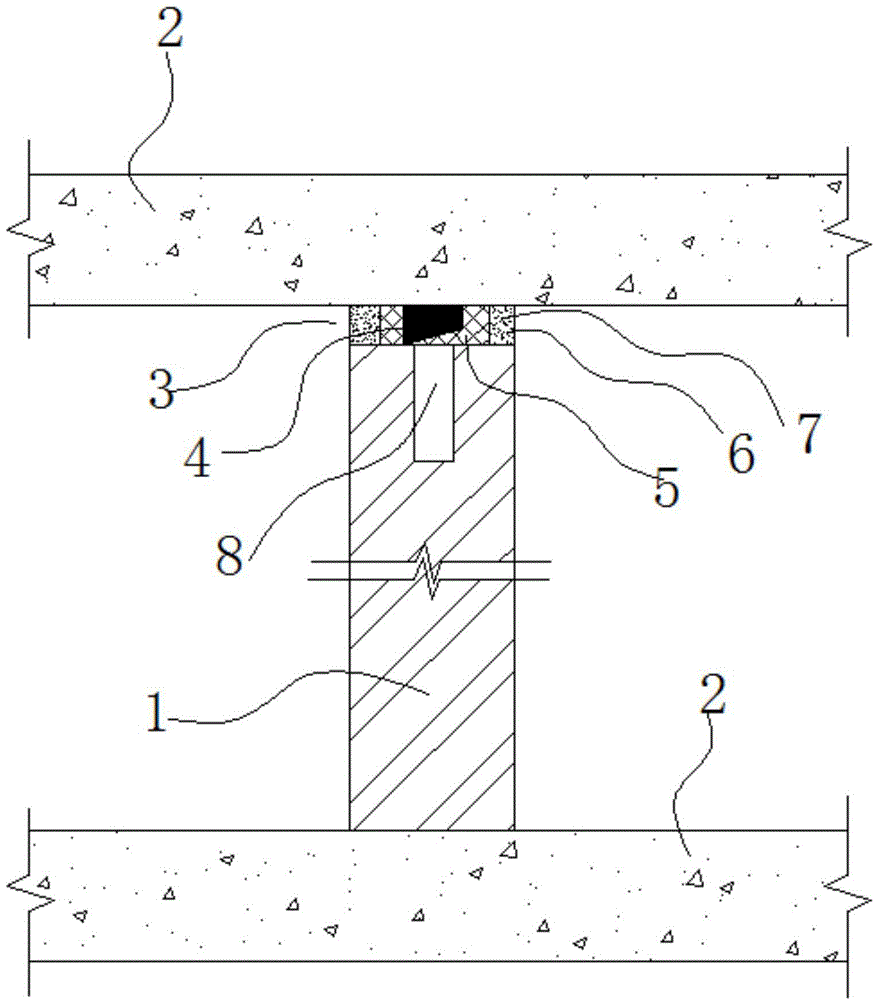

[0034] see figure 2 , this embodiment is basically the same as Embodiment 1, the difference is that there is a vacancy 8 in the top middle of the filling wall 1, and the filler 5 can at least plug the vacancy 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com