Connecting structures of single-compartment and multi-compartment steel pipe galleries and concrete pipe gallery

A technology for connecting structure and concrete, which is applied in the field of connection structure between single-cabin and multi-cabin steel pipe corridors and concrete pipe corridors, can solve the problems of difficult connection between steel pipe corridors and concrete pipe corridors, achieve good deformation coordination ability, solve connection difficulties, Effects of Constrained Displacement Deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

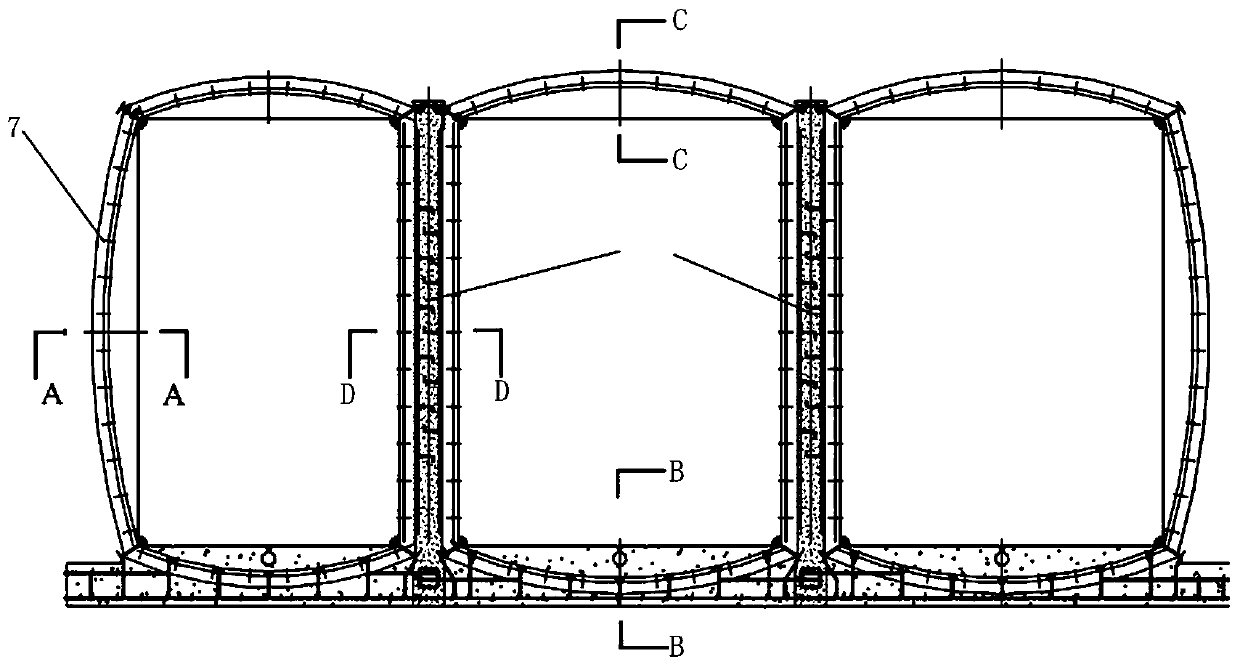

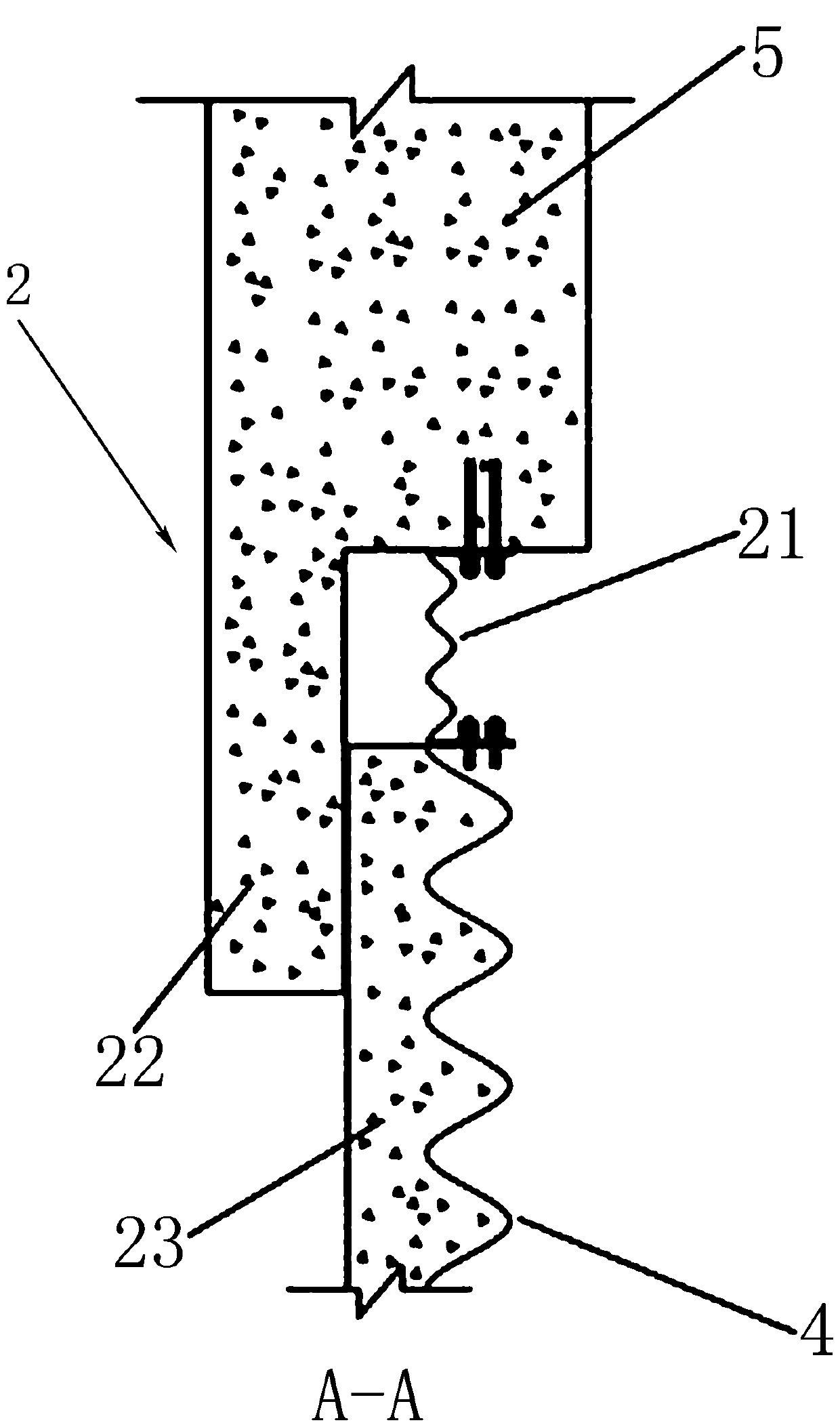

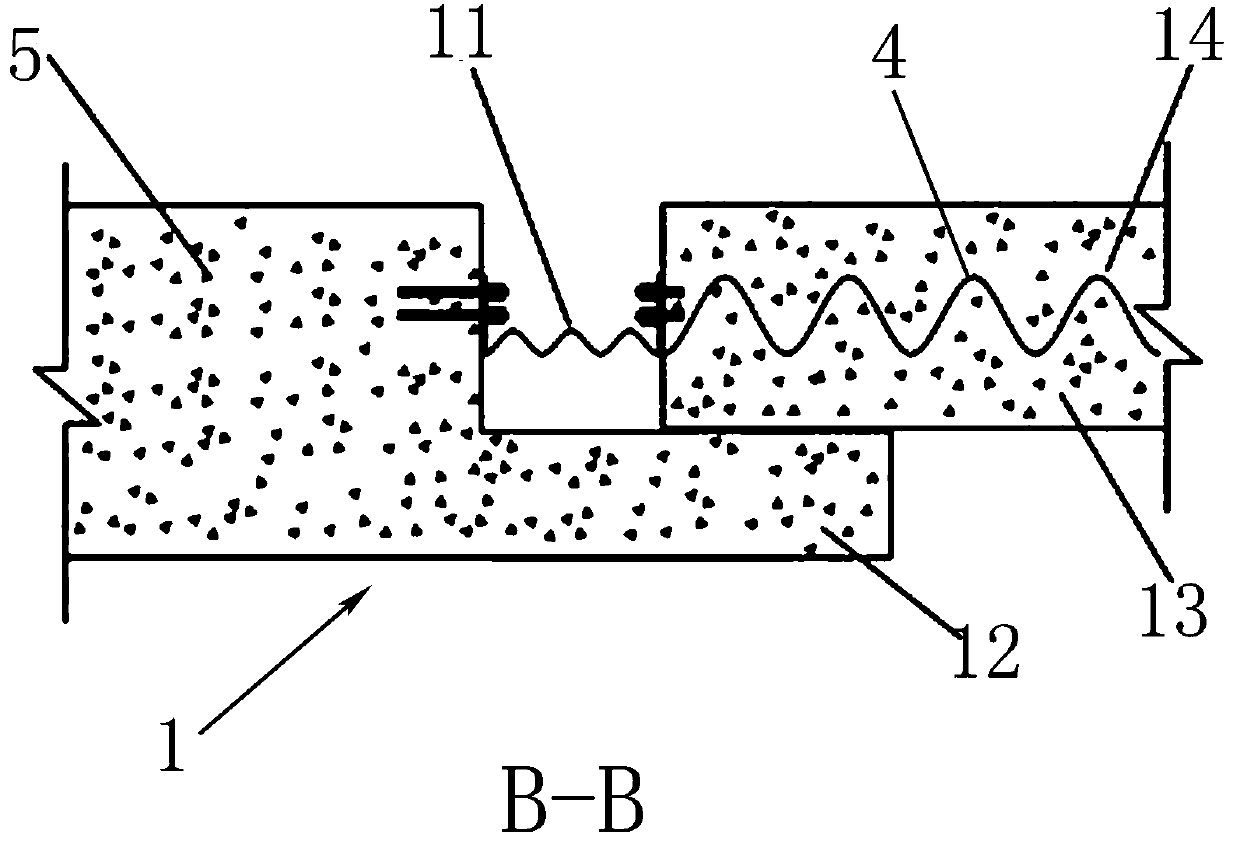

[0019] refer to Figure 1 to Figure 4 , a connection structure between a single-cabin and multi-cabin steel pipe gallery and a concrete pipe gallery of the present invention is composed of a bottom plate connection mechanism 1, a side wall connection mechanism 2 and a roof connection mechanism 3; the bottom plate connection mechanism 1 includes a first corrugated steel plate 11 and the first socket part 12 cast on the bottom end surface of the concrete pipe gallery 5, the first socket part 12 is located radially outside the bottom end surface of the concrete pipe gallery 5 and protrudes axially, and the first corrugated steel plate 11 One end of the single-chamber steel pipe gallery 4 is fixedly connected to the bottom end surface, and the other end is fixedly connected to the radial interior of the bottom end surface of the concrete pipe gallery 5. The outer side of the bottom of the single-chamber steel pipe gallery 4 is cast with a first concrete layer 13, and the single-cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com