Full-flexible unloading retaining wall and construction method

A fully flexible, load-retaining technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of rigidity, poor shock absorption and shock absorption performance, poor soil fusion, etc., to achieve good integrity and reduce deformation , High tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

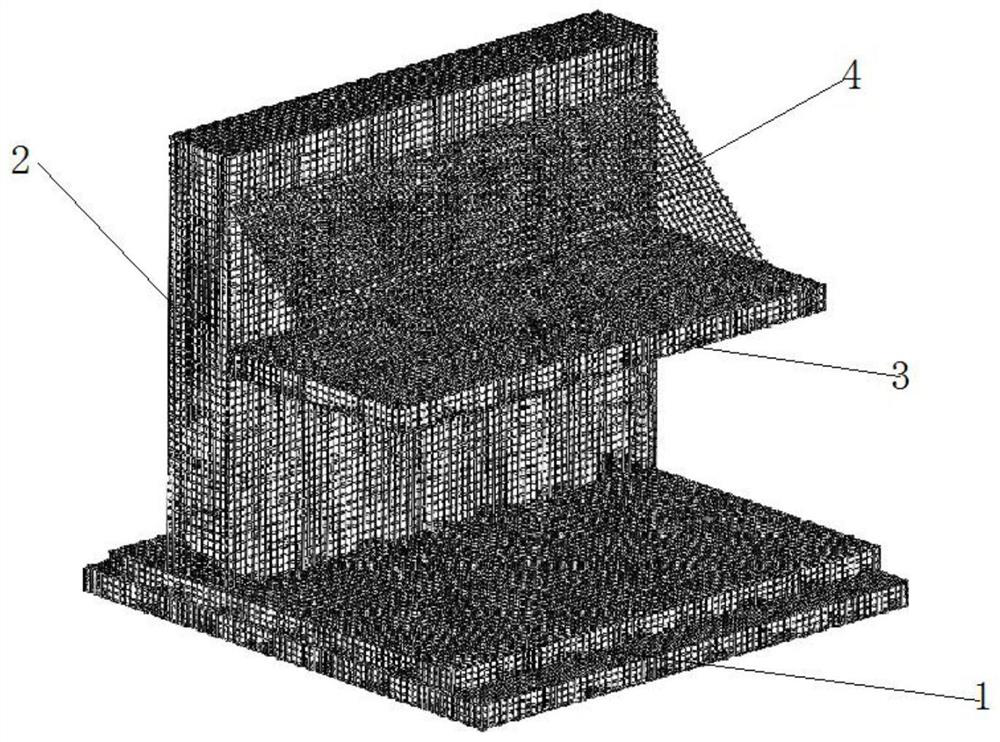

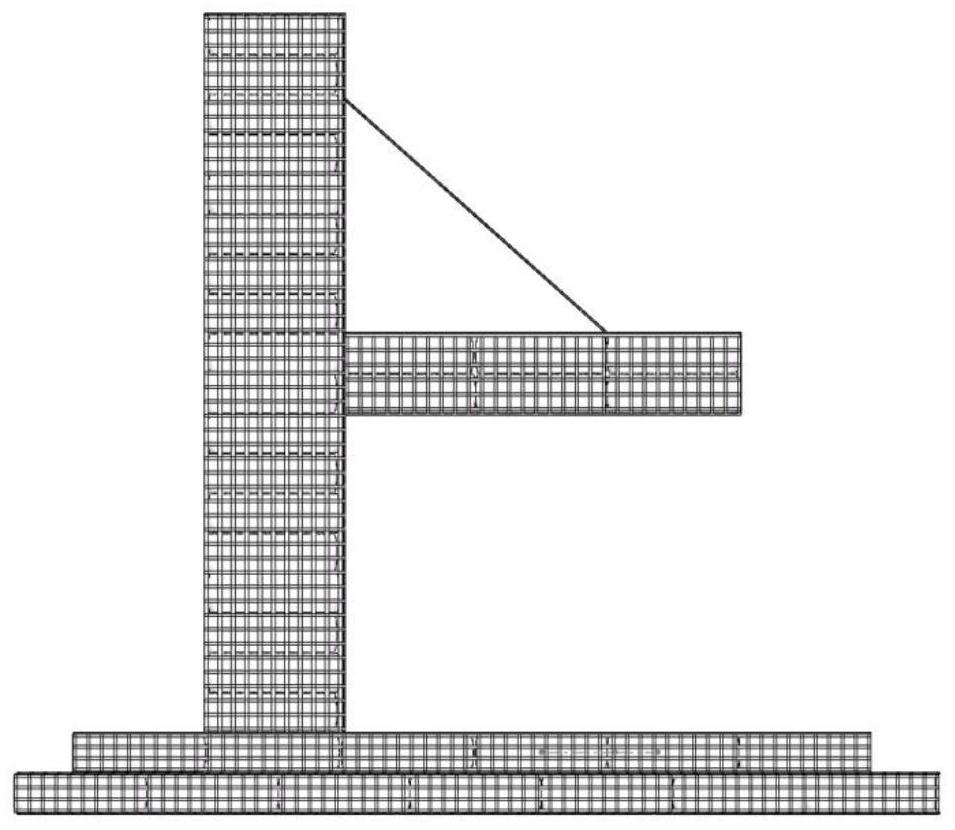

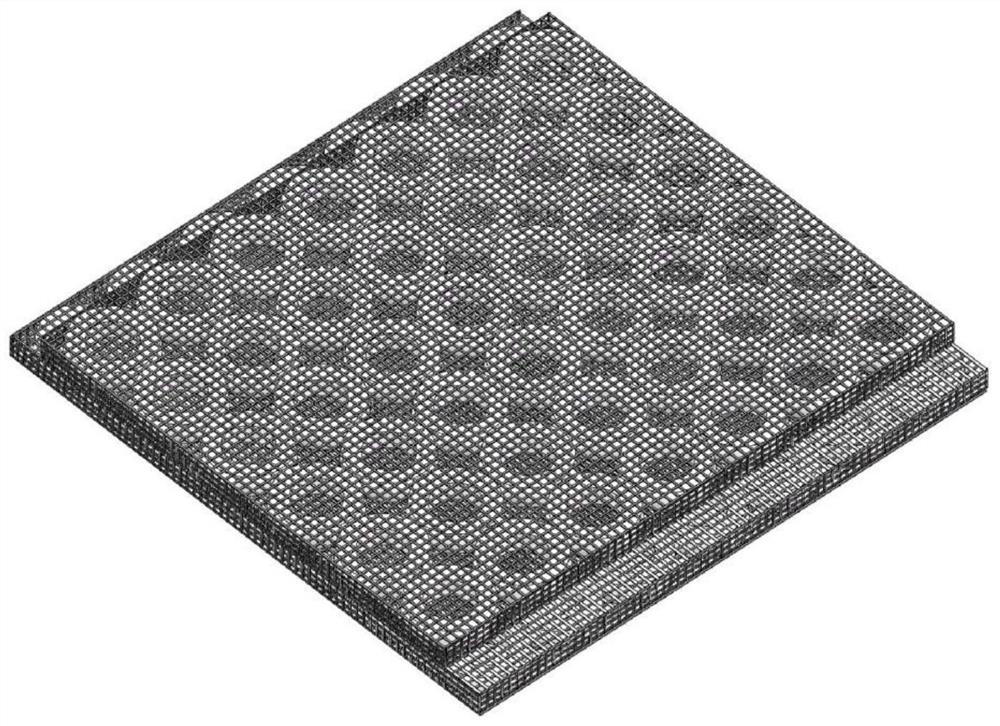

[0037] like Figure 1-16 As shown, the fully flexible unloading retaining wall disclosed by the present invention comprises a net cage bottom plate 1, a net cage baffle plate 2 and a net cage unloading plate 3, and a net cage baffle plate 2 is vertically set on the net cage bottom plate 1, and the net cage Unloading plate 3 is vertically arranged on the net cage baffle plate 2, and between the net cage baffle plate 2 and the net cage unloading plate 3, an unloading draw net 4 is arranged obliquely. Both the box unloading board 3 and the unloading net 4 are connected by locks, the bottom plate of the net cage is composed of a double-layer ladder tire layer 6 wrapped in a ladder net cage, and the net cage unloading board 3 is wrapped by a single-layer net cage 7 and a single-layer tire Layer 8 is formed, and each layer of tire layer includes several rows of tires filled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com