A deformed zinc-based alloy material and its preparation method and application

An alloy material, zinc-based technology, applied in the direction of metal/alloy conductors, contact parts, etc., can solve the problems of poor dimensional stability, poor mechanical properties, harmful zinc alloys, etc., achieve strong deformation coordination ability, improve machinability, plasticity Easy to process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

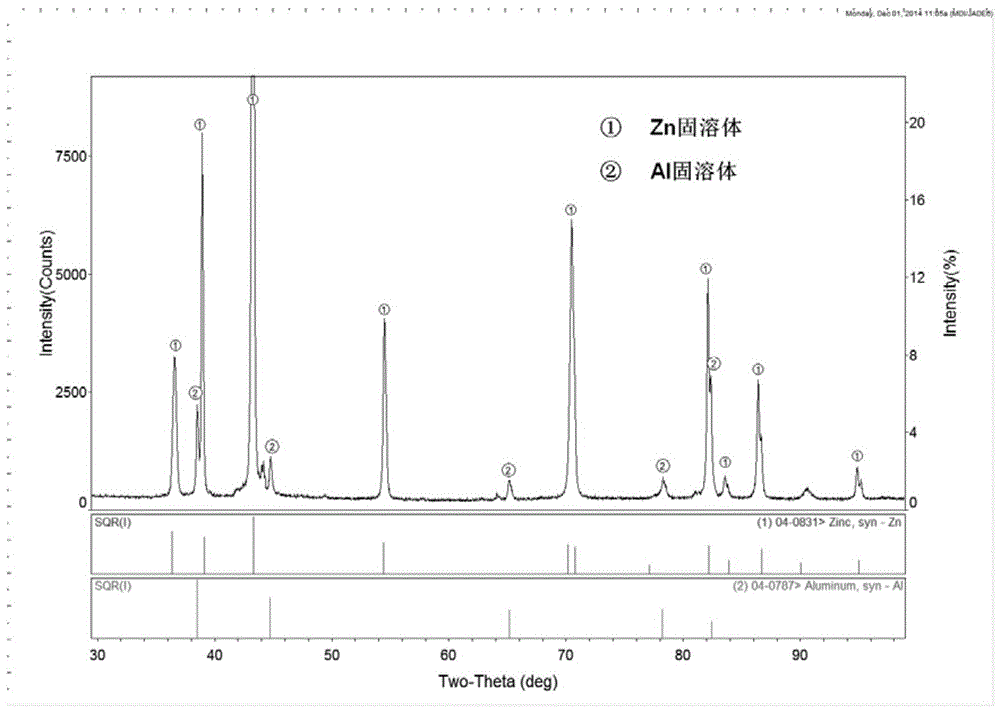

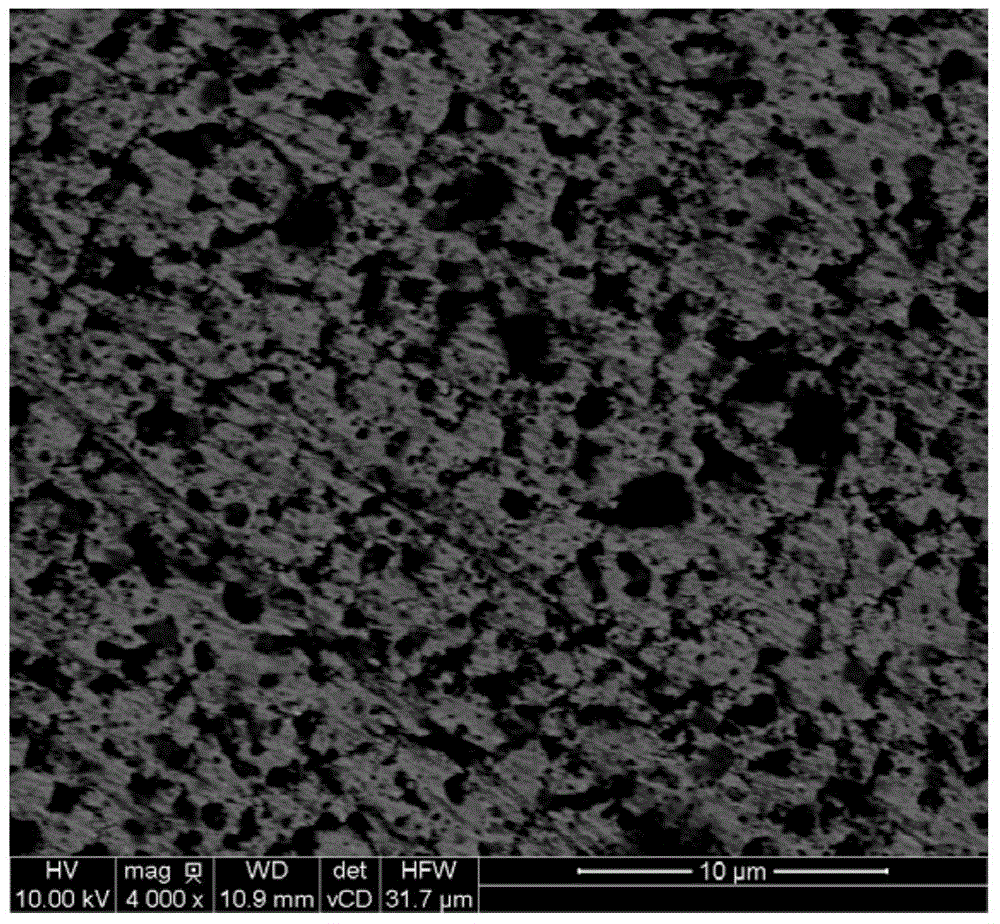

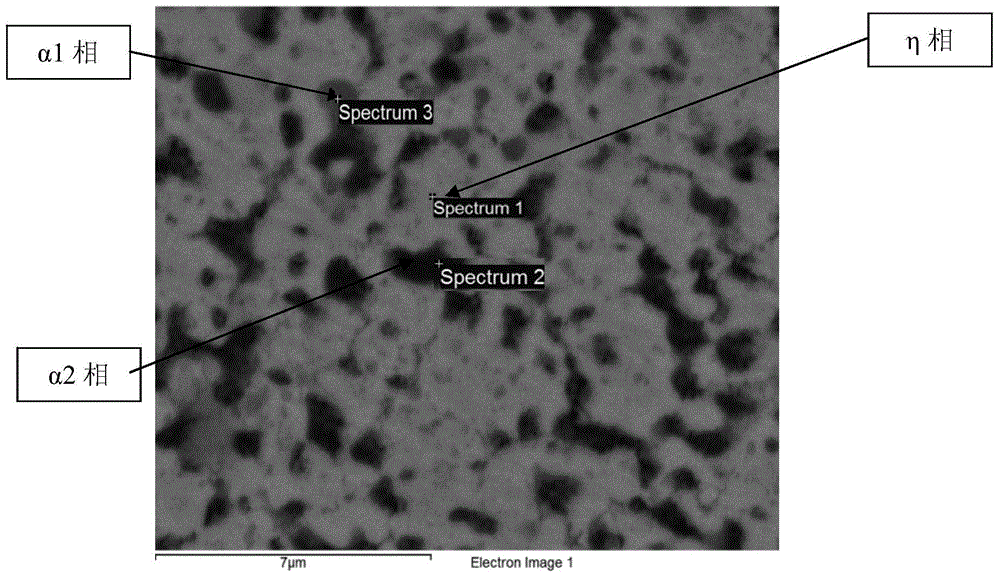

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0034] 25 example alloys and 1 comparative example alloy (C3604 lead brass) were selected, and the added elements were added to the smelting furnace according to their respective contents, and were produced by hot-top casting, semi-continuous casting or horizontal continuous casting into castings with a diameter of Φ40-350mm. Ingot, the cast ingot is sawed to a length of 200-1500mm after being extruded, heated to 180-370°C, extruded by a forward extruder or a reverse extruder to produce a billet of Φ4-45mm, stretched at least twice and at least two times of annealing to form a finished wire rod, the heat treatment temperature is 150°C-350°C, the heat treatment time is 1-10h, and then it is straightened.

[0035] The tensile test at room temperature is carried out on an electronic universal mechanical performance testing machine in accordance w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com