A method for detecting a deviation of an actual injection amount from a target fuel injection amount of an injector in an internal combustion engine

A technology of injector and internal combustion engine, applied in the direction of fuel injection control, internal combustion piston engine, combustion engine, etc., can solve the problem of time-consuming and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

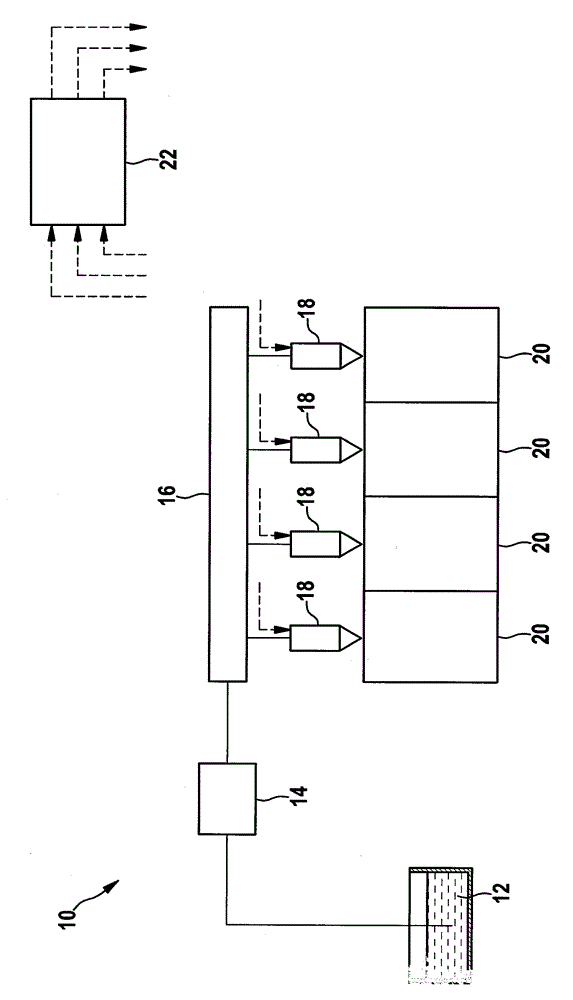

[0032] exist figure 1 A section of an internal combustion engine 10 is schematically shown in FIG. 2 , which includes a fuel storage container 12 from which fuel is pushed by means of a delivery system 14 into a high-pressure fuel line 16 . The high-pressure fuel line 16 is designed, for example, as a common rail. The high-pressure fuel line 16 is connected to a plurality of injectors 18 which enable the direct injection of fuel into the combustion chambers of the cylinders 20 which are each assigned to the injectors 18 . The operation of the internal combustion engine 10 and in particular the operation of the fuel injection system, which currently has a propulsion system 14 , a high-pressure fuel line 16 and an injector 18 , is controlled by a computing unit, here a controller 22 . Controller 22 enables the detection of input values, such as the current rotational speed, and the provision of output values or the activation of actuators, in particular injectors 18 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com