Missile launcher structure for oblique launching

A missile launcher, inclined launch technology, applied in the direction of the launch device, etc., can solve the problems of high system integration, high rigidity requirements, and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

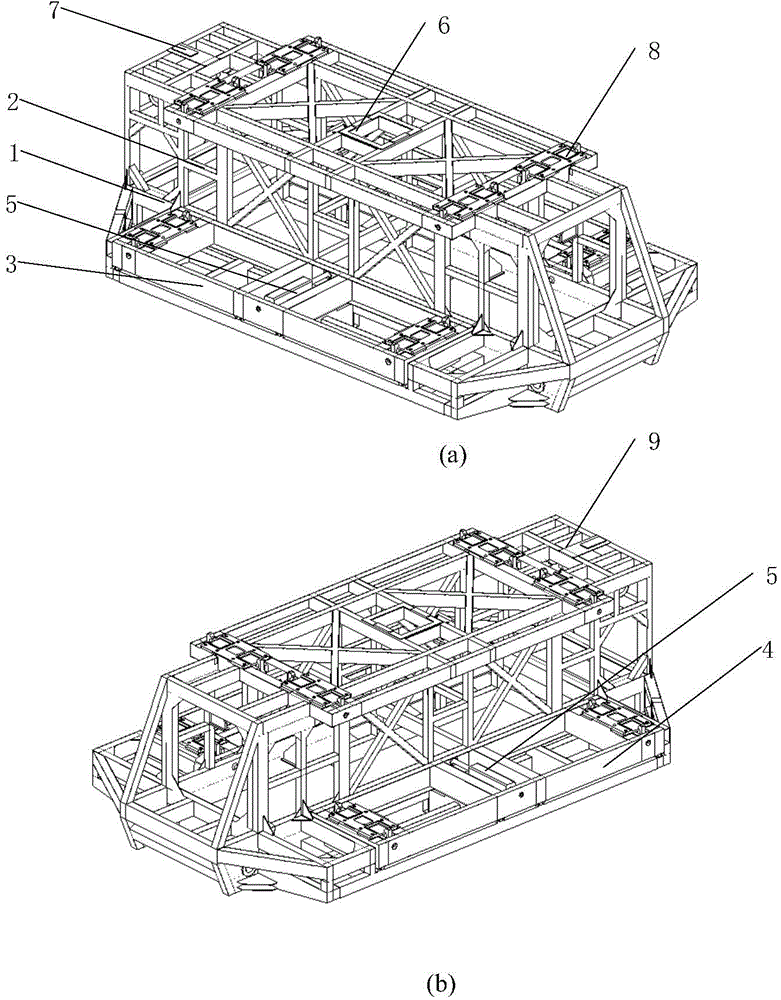

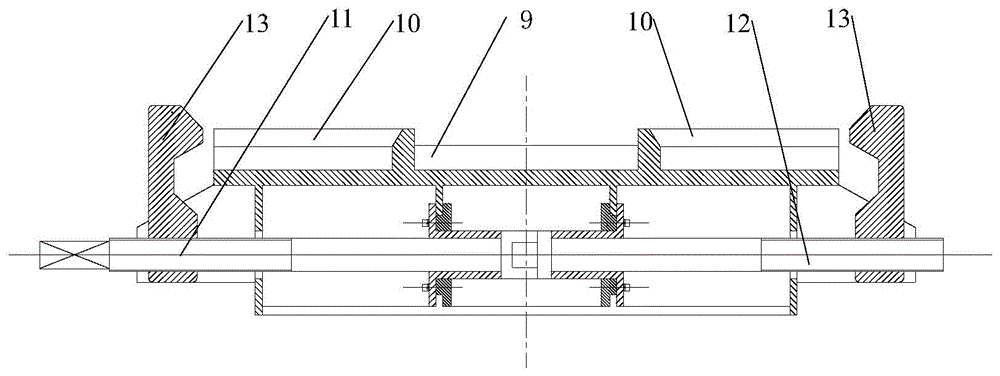

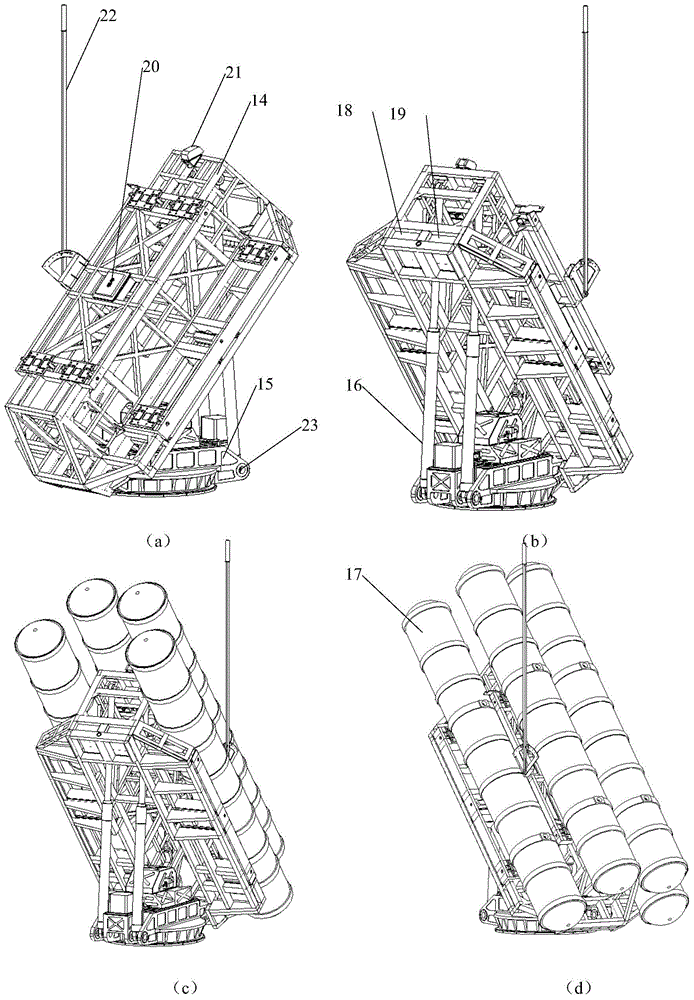

[0019] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0020] The launcher is formed by welding profiled steel pipes, which can hold 4 cartridges, and the upper and lower layers of the cartridges are symmetrically arranged in a trapezoid. After the launcher is loaded with bullets, it meets the requirements of vehicle driving and transportation. One end of the launching frame is installed on the lug of the azimuth turntable through a coupling shaft, the other end is connected with the extension end of the pitching and pushing cylinder, and the fixed end of the pitching and pushing cylinder is connected with the turntable; The launch frame is pushed to the launch angle by pitching and pushing the cylinder, and the 360-degree follow-up target can be realized through the azimuth turntable. In order to meet the needs of vehicle transportation and loading cartridges, the lower layer is designed with left and right attachm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com