Cable wear resistance testing device and method

A technology of wear resistance test and test method, which is applied in the direction of test wear resistance, etc., can solve problems such as rupture, safety accidents, cable insulation layer reduction, etc., and achieve the effect of ensuring reliability and environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

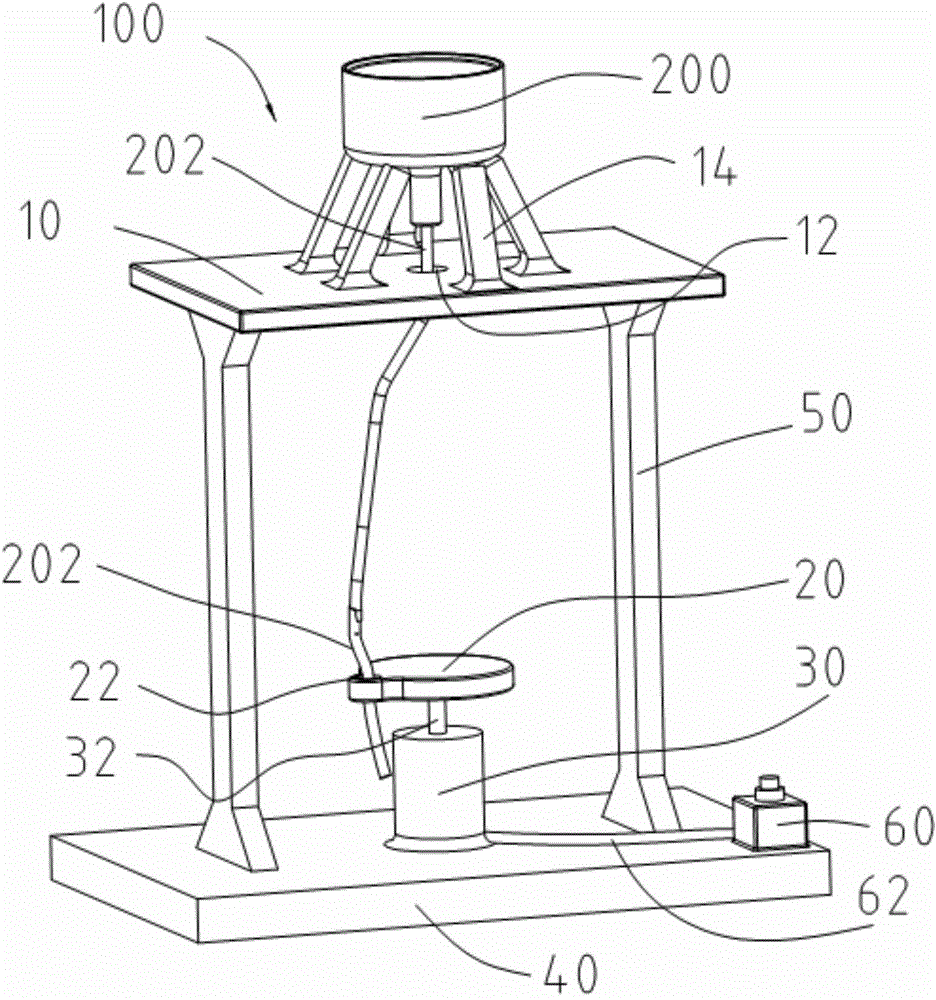

[0018] see figure 1 , the present invention provides a cable wear-resistant test device 100, the cable wear-resistant test device 100 includes a lamp bracket 10, a turntable 20 and a driving member 30, the lamp bracket 10 is used to support the lamp 200, the turntable 20 is set There is a first through hole 22, the driving member 30 is used to drive the turntable 20 to rotate, the cable 202 of the lamp 200 passes through the first through hole 22, during the rotation of the turntable 20, the The skin of the cable 202 is subjected to frictional force, so as to test the abrasion resistance of the cable 202 . In this embodiment, the first through hole 22 is disposed on the edge of the turntable 20 .

[0019] Specifically, the cable abrasion test device 100 also includes a chass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com