Paint film testing device and method

A technology for testing devices and testing methods, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., which can solve problems such as the performance degradation of the protective layer of lamps, corrosion of the shell, and potential safety hazards of live parts, so as to ensure reliability and environmental adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

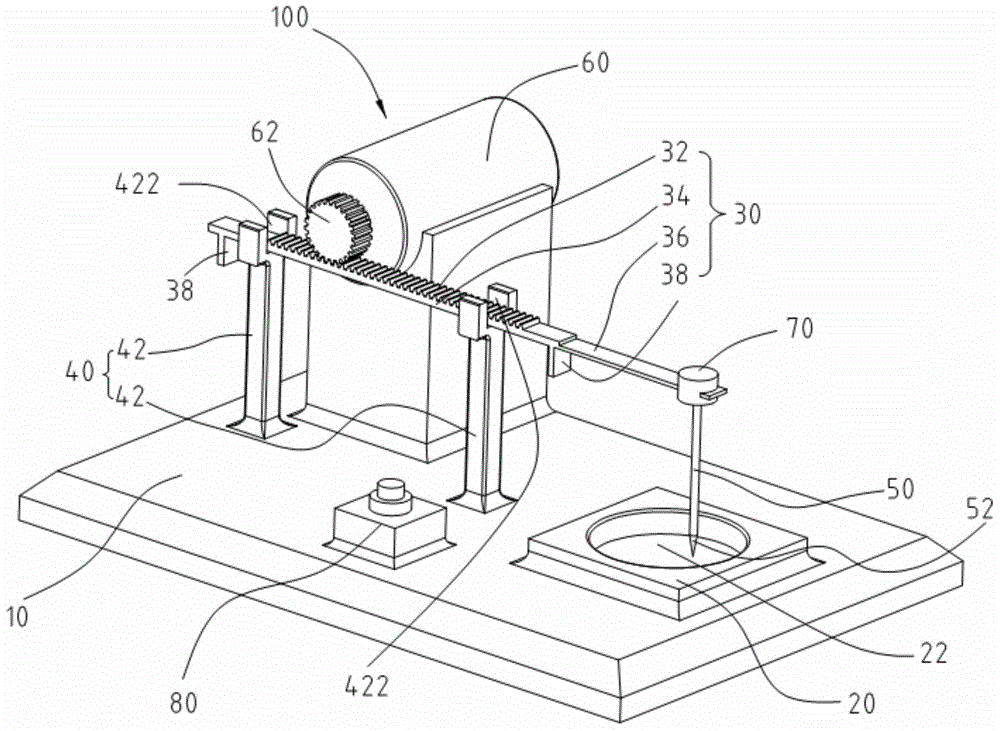

[0018] see figure 1 , the present invention provides a paint film testing device 100, the paint film testing device 100 includes a chassis 10, a sample placement platform 20, a pull arm 30, a bracket 40, a test needle 50 and a driving member 60, and the sample placement The stage 20 is arranged on the chassis 10 for positioning the sample to be tested (not shown), the bracket 40 extends vertically upward from the chassis 10 to support the pull arm 30, and the test needle 50 is connected to The pull arm 30, the needle point 52 of the test needle 50 extends to the sample placement table 20 and is close to the surface of the sample to be tested, and the pull arm 30 is driven by the driving member 60 to be able to relatively The support 40 moves back and forth, so that the tip 52...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com