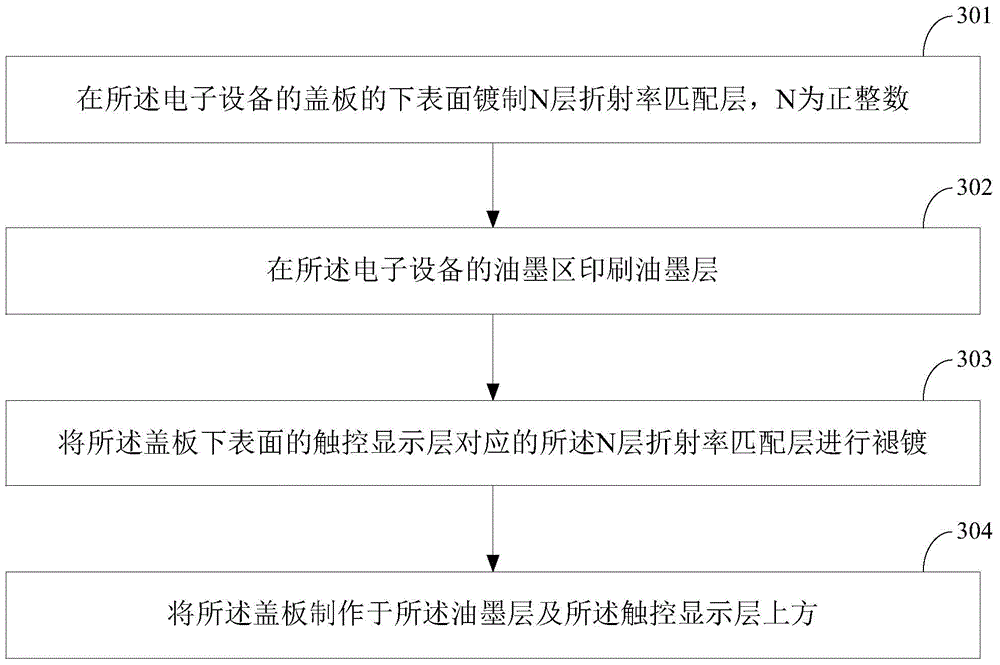

Electronic instrument and electronic instrument manufacturing method and device

A kind of electronic equipment and plating technology, applied in the direction of telephone structure, electrical digital data processing, data processing input/output process, etc., can solve the problem that the visual effect of the screen window area and the ink area cannot be consistent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

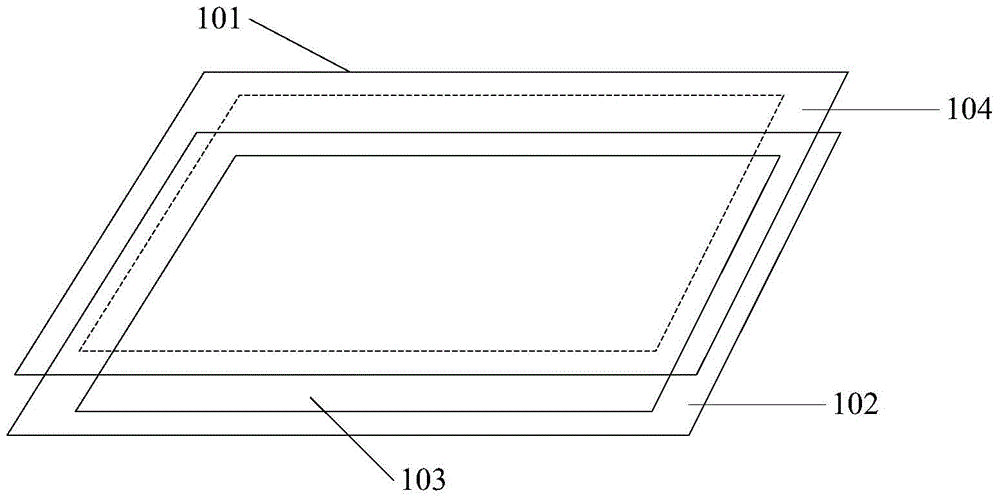

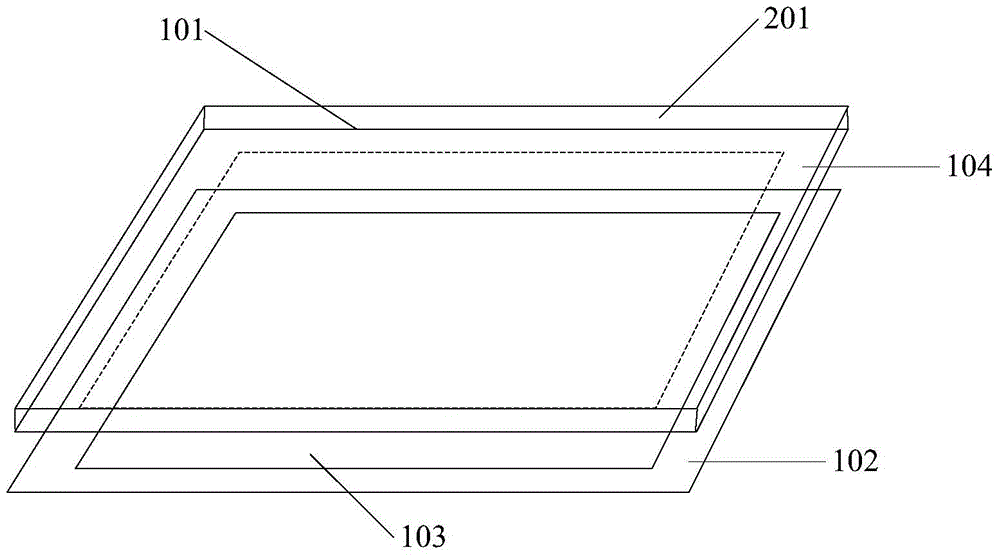

[0055] For example, the refractive index matching layer 104 uses high refractive index film material Nb2O5 (refractive index at 550nm wavelength is 2.3) and low refractive index film material Al2O3 (refractive index at 550nm wavelength is 1.63), which is based on the high and low refractive index The choice is based on the principle that the difference between the film layers is relatively large and it is easy to achieve refractive index matching.

[0056] The refractive index matching layer 104 is realized by having a symmetrical film layer structure, and the increase in the number of film layers will reduce the adhesion of the film, so the symmetrical film system Al2O3 / Nb2O5 / Al2O3 film layer structure with the least number of film layers is used, that is, N=3 , there are three refractive index matching layers 104, wherein the material of the first refractive index matching layer 104 is Al2O3, the material of the second refractive index matching layer 104 is Nb2O5, and the mat...

example 2

[0059] The refractive index matching layer 104 is made of high refractive index film material CeO2 (refractive index at 550nm wavelength is 2.20) and low refractive index film material Al2O3 (refractive index at 550nm wavelength is 1.63), which is based on the high and low refractive index film layer The larger the difference, the easier it is to realize the principle of refractive index matching.

[0060] The refractive index matching layer 104 is realized by having a symmetrical film layer structure, and the increase in the number of film layers will reduce the adhesion of the film, so the symmetrical film system Al2O3 / CeO2 / Al2O3 film layer structure with the least number of film layers is used, that is, N=3 , there are three refractive index matching layers 104, wherein the material of the first refractive index matching layer 104 is Al2O3, the material of the second refractive index matching layer 104 is CeO2, and the material of the third refractive index matching layer 10...

example 3

[0070] For example, the refractive index matching layer 104 uses high refractive index film material Nb2O5 (refractive index at 550nm wavelength is 2.3) and low refractive index film material Al2O3 (refractive index at 550nm wavelength is 1.63), which is based on the high and low refractive index The choice is based on the principle that the difference between the film layers is relatively large and it is easy to achieve refractive index matching.

[0071] The refractive index matching layer 104 is realized by having a symmetrical film layer structure, and the increase in the number of film layers will reduce the adhesion of the film, so the symmetrical film system Al2O3 / Nb2O5 / Al2O3 film layer structure with the least number of film layers is used, that is, N=3 , there are three refractive index matching layers 104, wherein the material of the first refractive index matching layer 104 is Al2O3, the material of the second refractive index matching layer 104 is Nb2O5, and the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com