Splitting method and system for touch panel stuck by OCA glue

A technology of touch panel and adhesive bonding, which is applied in the direction of chemical instruments and methods, layered products, data processing input/output process, etc. It can solve the problems that cannot be disassembled and cannot be disassembled, and achieve high efficiency of disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This example provides a method for disassembling an OCA glued touch panel, including the following steps:

[0023] A sealing step, sealing the touch panel bonded with the disassembled OCA glue;

[0024] The cooling step is to cool down the sealed touch panel, so that the ambient temperature of the touch panel is kept between minus 90°C and minus 150°C until the freezing time reaches the preset first time period;

[0025] And, the disassembly step is to take out the frozen touch panel, and use a hard tool to cut off the sensor and cover of the touch panel.

[0026] In this example, the OCA glue-bonded touch panel is placed in a freezing environment of minus 90°C to minus 150°C for a fixed period of time, so that the OCA glue will undergo a qualitative change without negatively affecting the sensor and cover. Therefore, The disassembly of the OCA glued touch panel can be well realized; the sensor is a sensor.

[0027] In the cooling step described in this example, the t...

Embodiment 2

[0030] On the basis of Embodiment 1, the splitting step described in this example also includes a static sub-step, and the static sub-step takes out the frozen touch panel until the static time reaches the preset second time period. cut open. By setting the static sub-step in the splitting step, neither the sensor nor the cover of the touch panel will be too fragile after freezing, and the probability of damage to the sensor and the cover during the cutting process is reduced.

[0031] In the sub-step of resting in this example, the preset second time period is 30s to 300s. More preferably, in the standing sub-step, the preset second time period is 60s to 180s.

[0032] In this example, after taking out the frozen touch panel, let it stand for half a minute to 5 minutes, or preferably about 1 minute, so that the disassembly of the touch panel can be more efficient without damaging the sensor that needs to be cut and cover plate.

Embodiment 3

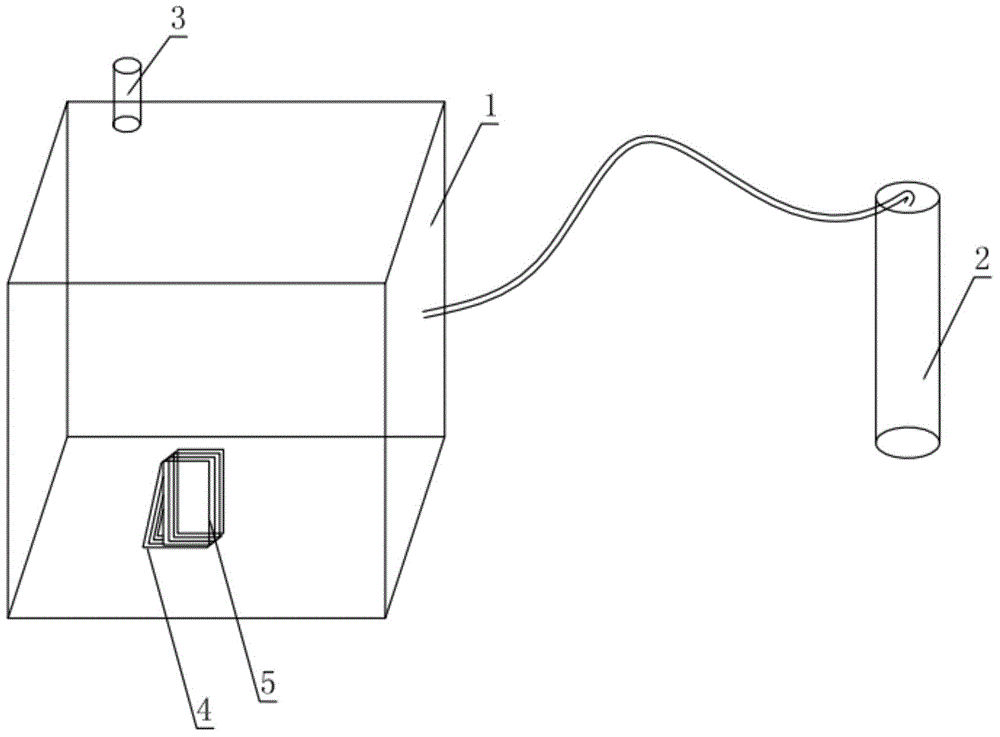

[0034] Such as figure 1 As shown, this example also provides a dismantling system of an OCA glued touch panel, which adopts the dismantling method of the touch panel described in Embodiment 1 or Embodiment 2, and includes a sealed container 1 and liquid nitrogen The input device 2, the sealed container 1 includes a thermometer 3 and a touch panel slot; the thermometer 3 is arranged on the sealed container 1, and its temperature reading area extends out of the sealed container 1; the touch panel slot is used The touch panel 5 is inserted and placed in the airtight container 1; the liquid nitrogen input device 2 is connected to the airtight container 1, and is used to fill the airtight container 1 with liquid nitrogen to cool down.

[0035] Fill the airtight container 1 with nitrogen through the liquid nitrogen input device 2 until the thermometer 3 shows that the temperature of the freezing environment reaches minus 30°C, then stop the input of liquid nitrogen. In this way, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com