Portable electric threader

A threader and portable technology, applied in the field of portable electric threader, can solve the problems of manual injury accidents caused by wire rope scratches, unrecoverable steel wires, and obstruction of the forward movement of steel wires, so as to achieve convenient storage and carrying, fast and smooth threading, clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

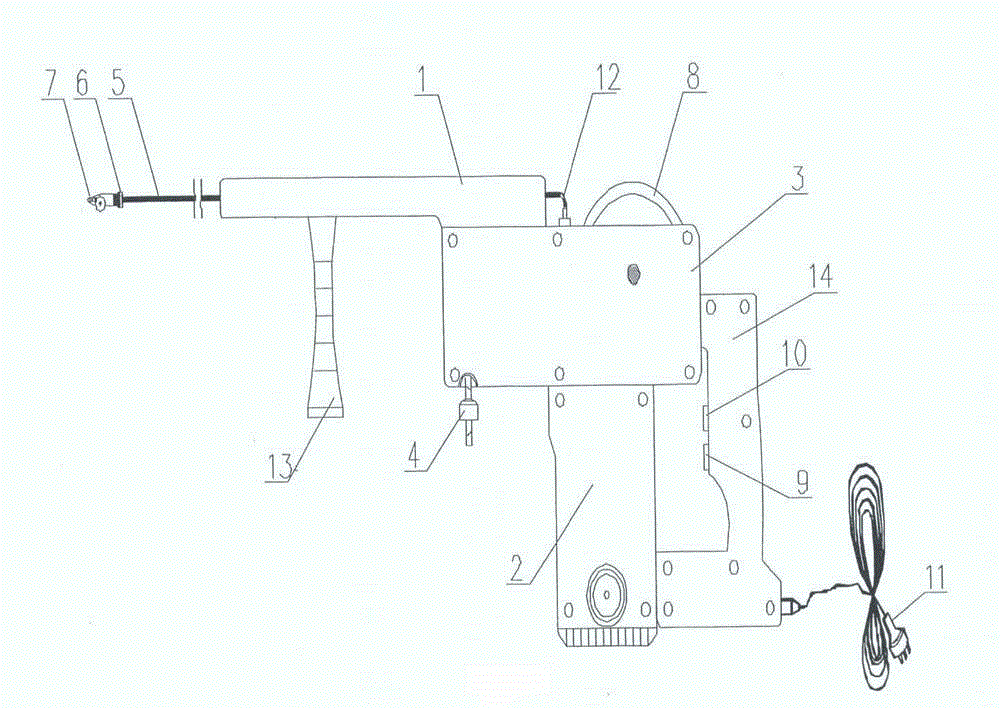

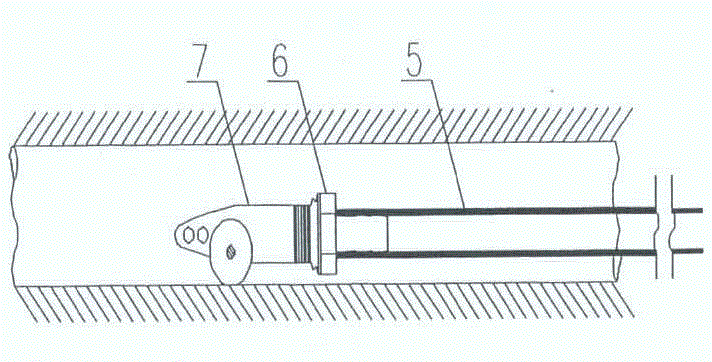

[0038] Below in conjunction with accompanying drawing of description, the present invention is described in detail, just as the accompanying drawing of description figure 1 , figure 2 Shown:

[0039] A portable electric needle threader, which consists of a casing 1, a motor 2, an air pump 3, a filter 4, a hose 5, a joint 6, a warhead 7, a wheel 8, a motor switch 9, an air pump switch 10, a plug 11, an air charging port 12, Handle 13, rear seat 14 constitute;

[0040] The portable electric needle threader, the lower side of the front section of the housing 1 and the upper end of the handle 13, the lower side of the rear end section of the housing 1 and the upper side of the air pump 3, the lower side of the air pump 3 and the motor 2, the rear side of the air pump 3 and the upper end of the rear seat 14, the rear The lower end of the seat 14 is fixedly connected with the motor 2 and the back seat 14 internally with the motor switch 9 and with the air pump switch 10. One side...

specific Embodiment approach 2

[0046] Carry out on the implementation basis of specific embodiment one, just: when applying portable electric needle threader to carry out threading, the perforation that the front end of described bullet 7 is provided with is fixedly connected with the lead wire that is worn and the pulley that bullet 7 middle is provided with needs Threaded pipe slip unions were implemented; also with good results as expected.

specific Embodiment approach 3

[0047] Carry out on the basis of the implementation of the specific embodiment one, just: when using the portable electric threader to remove impurities in the pipeline, the perforation provided at the front end of the bullet 7 is fixedly connected with the brush and the pulley and the pipeline provided in the middle of the bullet 7 Sliding live connections were implemented; also with good results as expected.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap