Cold-rolling strip steel threading method

A cold-rolled strip steel and strip steel technology, which is applied in the field of strip steel rolling, can solve problems such as damage to the surface of work rolls, impact on strip threading time, and impact on product surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

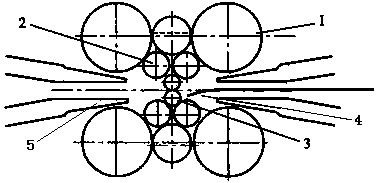

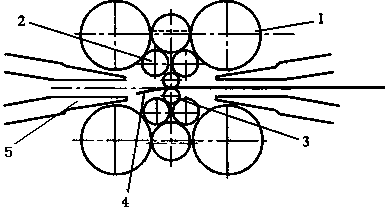

[0019] figure 1 , figure 2 A schematic diagram of the belt threading operation in the prior art is shown. figure 1 , the strip head 4 is inserted into the gap between the work roll 3 and the intermediate roll 2, figure 2 In the process, the strip steel head 4 was inserted under the oil injection guide plate 5, which caused the belt to not be threaded smoothly and damaged the surface of the work roll.

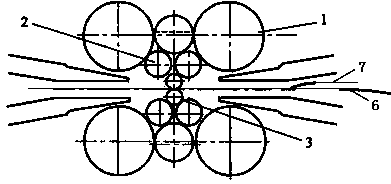

[0020] image 3 It is a schematic diagram of the belt threading method provided by the present invention. The tail 6 of the last roll of strip steel and the head 7 of the next roll of strip steel form a formula that overlaps up and down. The method includes the following steps:

[0021] (1) After the rolling of the last coil of strip steel is completed and the strip tail is separated from the jaws, do not rush to pull the strip tail through the rolling mill so that the tail is located 0.5 meters outside the turning roll at the entrance of the rolling mill;

[0022] (2) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com