Power cable core recycling device and using method thereof

A recycling device and power cable technology, applied in the direction of dismantling/armoring cable equipment, etc., can solve the problems of cable core scratches, low efficiency, and heavy operation, and achieve the effect of increasing controllability and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

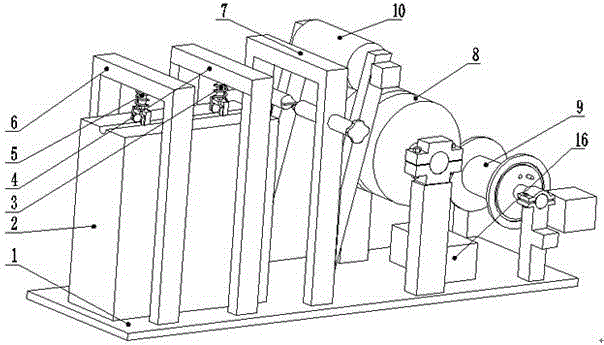

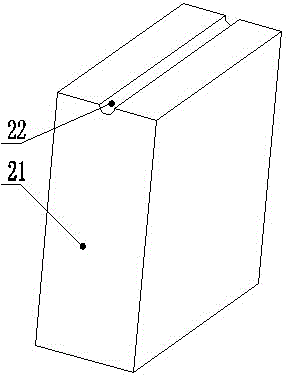

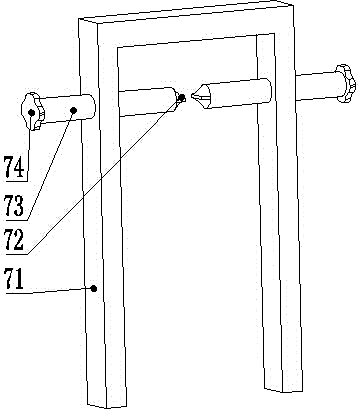

[0105] Such as Figure 1 to Figure 11 As shown, the present invention proposes a power cable core recovery device, which includes a base plate 1, a positioning body 2 is provided at the front end of the base plate 1, and a first pressure frame 6 is provided on both sides of the positioning body 2. A pressure frame 6 is provided with a first pressure wheel 5, a cutting mechanism 7 is provided behind the positioning body 2, a skin rolling mechanism 10 is arranged on the cutting bracket 71 of the dividing mechanism 7, and the cutting mechanism 10 is fixedly connected to the On the base plate 1, a winding mechanism 9 is arranged behind the cutting mechanism 7, and the winding mechanism 9 is fixedly connected to the base plate 2. A control box 16 is also arra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap