Automatic high-efficiency denumbing machine

An automatic technology for removing hemp, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of poor processing quality, unfavorable unloading of hemp, large loss, etc., and achieve automatic unloading of hemp, convenient fiber collection, and high production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

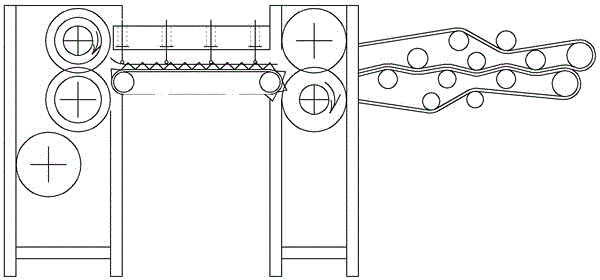

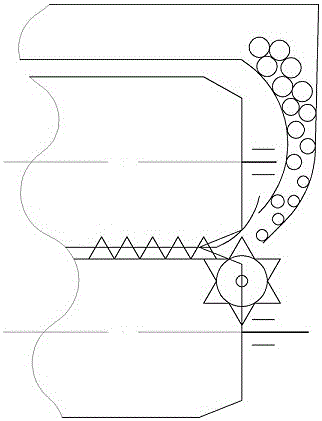

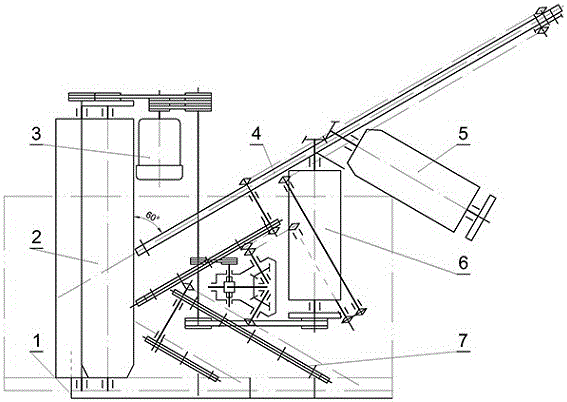

[0022] Such as figure 1 , figure 2 As shown, it consists of a feeding port 1, a hemp stalk clamping and conveying mechanism 7, three sets of denumbing mechanisms 2, 6, and 5 on the left, middle and right, a fiber clamping and conveying mechanism 4, and a power and transmission device 3. The hemp stalk clamping and conveying mechanism is composed of two feed chains and one reverse pull-out feed chain, which is arranged at an inclination of 60° to the de-hemp mechanism. The feed chain and reverse pull-out feed chain form a V shape, and the second feed chain The head and tail of the input chain and the reverse pull-out feeding chain are slightly overlapped on the same horizontal line, so as to realize the clamping, conveying, reversing and handover of the hemp stalks. The fiber clamping conveyor belt is arranged in parallel behind the reverse pull-out feeding clamping chain. When the reverse pull-out feed chain pulls out the fiber and feeds the hemp stalk to the de-semp mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com