Absorptive robot and steering control method for same

A technology of steering control and robot, which is applied in the direction of automatic control of traveling motion, window cleaning, cleaning equipment, etc., can solve problems such as inability to steer or complicated steering, solve technical problems and reduce possible sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

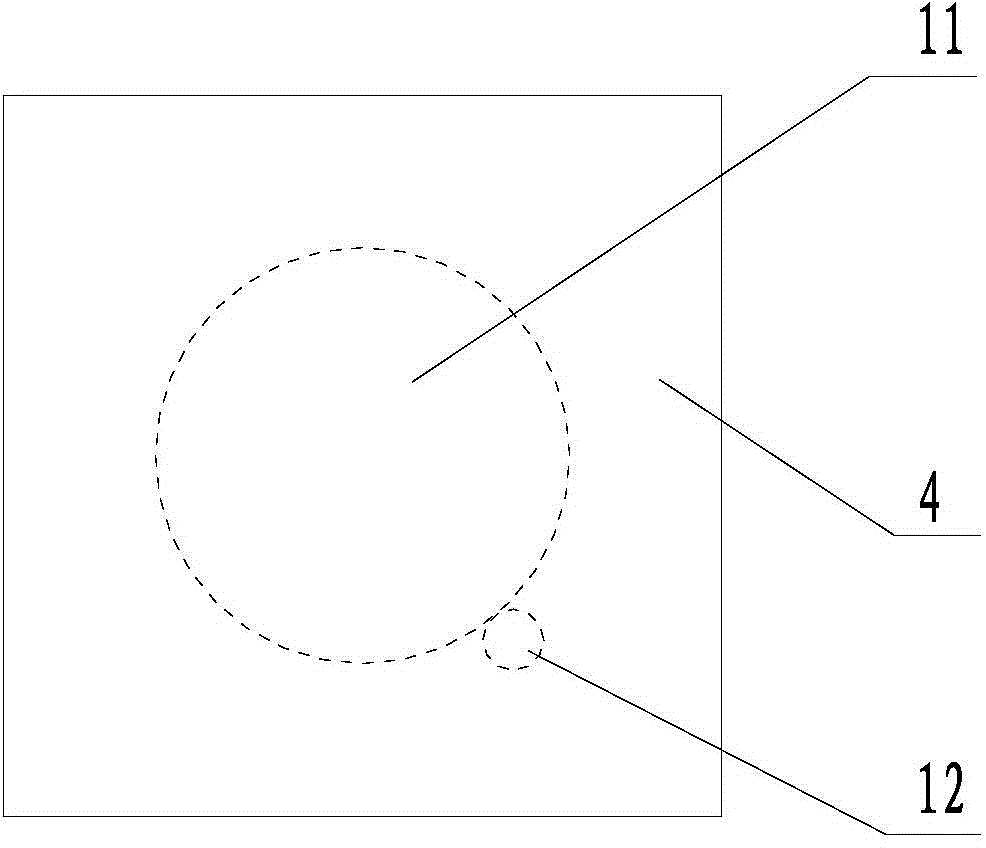

[0027] figure 1 It is a structural schematic diagram of the rotating mechanism of Embodiment 1 of the present invention, such as figure 1 As shown, the rotating mechanism includes: a bull gear 11, a pinion 12 meshing with the bull gear 11 and a driving mechanism 3 for driving the pinion 12, the pinion 12 is fixedly connected with the body 4, and the The large gear 11 is fixedly connected with the suction cup, and the large gear is rotatably arranged on the body.

[0028] Working principle: when the adsorption robot turns, the suction cup is adsorbed on the working surface, the suction cup and the large gear 11 fixedly connected with the suction cup are fixed, and the driving mechanism 3 drives the small gear 12 to rotate. Because the body 4 is fixedly connected to the small gear 12, when When the pinion gear 12 rotates, it drives the entire body 4 to rotate around the center of the bull gear 11 as the center of rotation, thereby completing the steering of the adsorption robot...

Embodiment 2

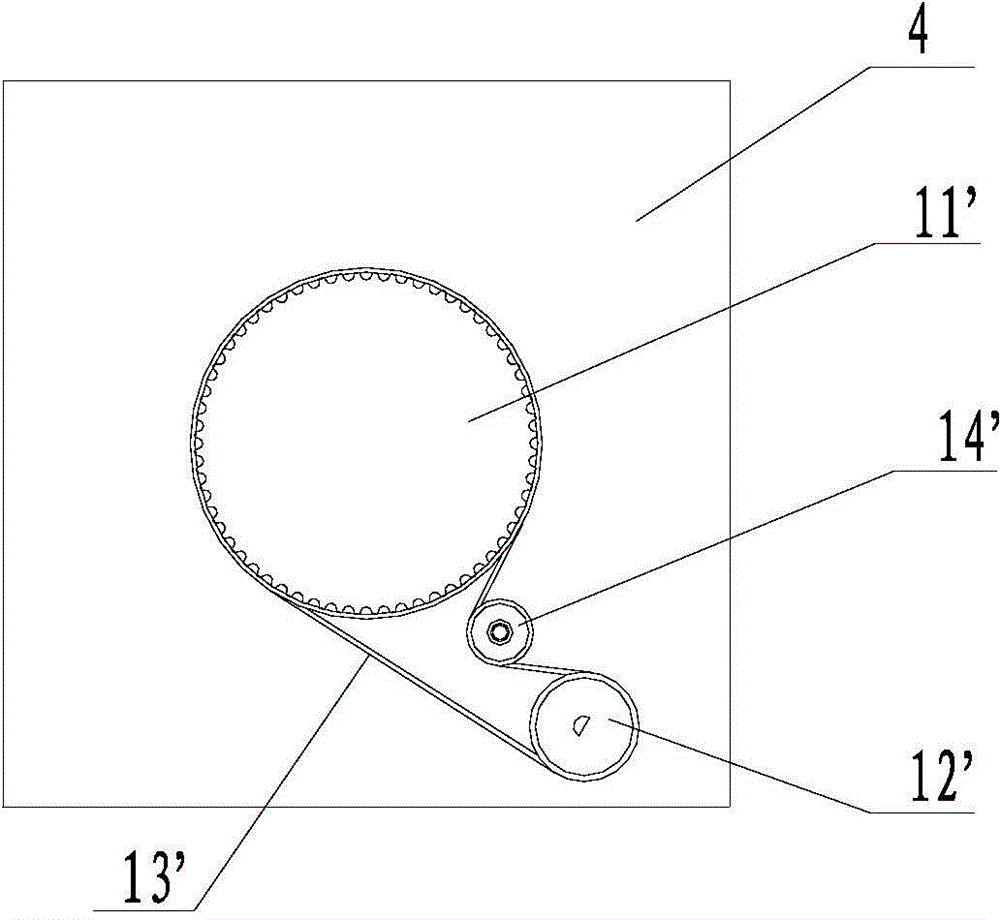

[0030] figure 2 It is a structural schematic diagram of the rotating mechanism of Embodiment 2 of the present invention, such as figure 2 As shown, the rotating mechanism provided in this embodiment includes: a large gear 11', a driving wheel 12' connected to the large gear 11' through a belt 13', a driving mechanism 3 for driving the driving wheel 12', and a tensioning wheel 14 ', the tensioning wheel 14' is located between the bull gear 11' and the driving wheel 12', and is connected with the bull gear 11' and the driving wheel 12' through a belt 13', and the driving wheel 12' is connected to the The body 4 is fixedly connected, and the large gear 11' is fixedly connected with the suction cup. The large gear is connected with the body through a bearing, the large gear is connected with the outer ring of the bearing, and the body is connected with the inner ring of the bearing.

[0031] Working principle: when the adsorption robot turns, the suction cup and the large gear...

Embodiment 3

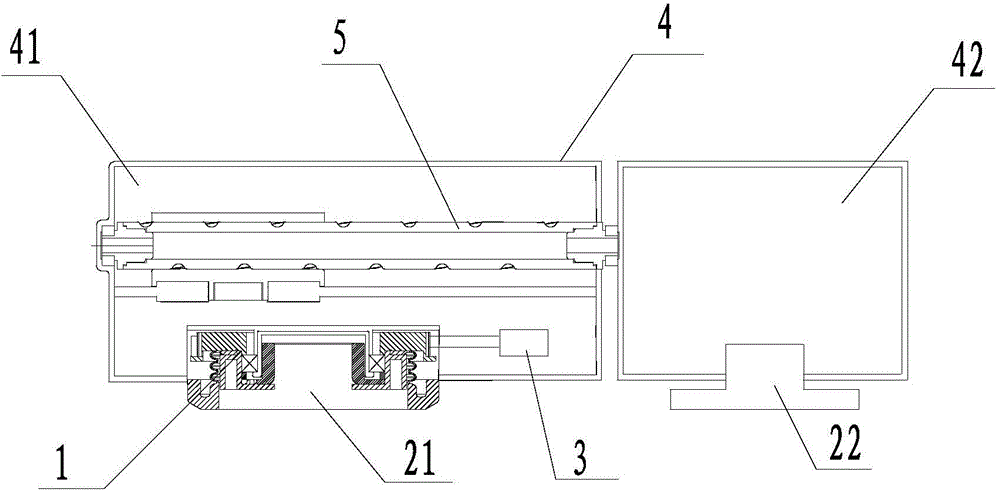

[0033] image 3 It is a schematic diagram of the structure of the rotating mechanism set in the front body of the third embodiment of the present invention. The rotating mechanism of the adsorption robot in this embodiment is suitable for any of the above-mentioned rotating mechanisms, such as image 3 As shown, it includes: a body 4, the bottom of the body 4 is provided with a suction cup 2 for absorbing the working surface, the adsorption robot is also provided with a rotating mechanism 1, the suction cup is connected to the body 4 through the rotating mechanism 1, and the body 4 is driven by The rotation mechanism 1 makes the body rotate at a preset angle relative to the suction cup, thereby completing the steering of the robot.

[0034] Specifically, in this embodiment, the adsorption robot is a split adsorption robot, including: a body 4, the body 4 includes: a front body 41 and a rear body 42 connected by a drive assembly 5, and the drive assembly 5 can Adopt leading sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com