Mining method of open field and subsequent filling in extremely thick and large ore body stage under strong ground pressure environment

A technology for filling mining and ore bodies, which is applied in underground mining, ground mining, fillings, etc., can solve problems such as potential safety hazards, and achieve the effects of small mining volume, high production efficiency, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

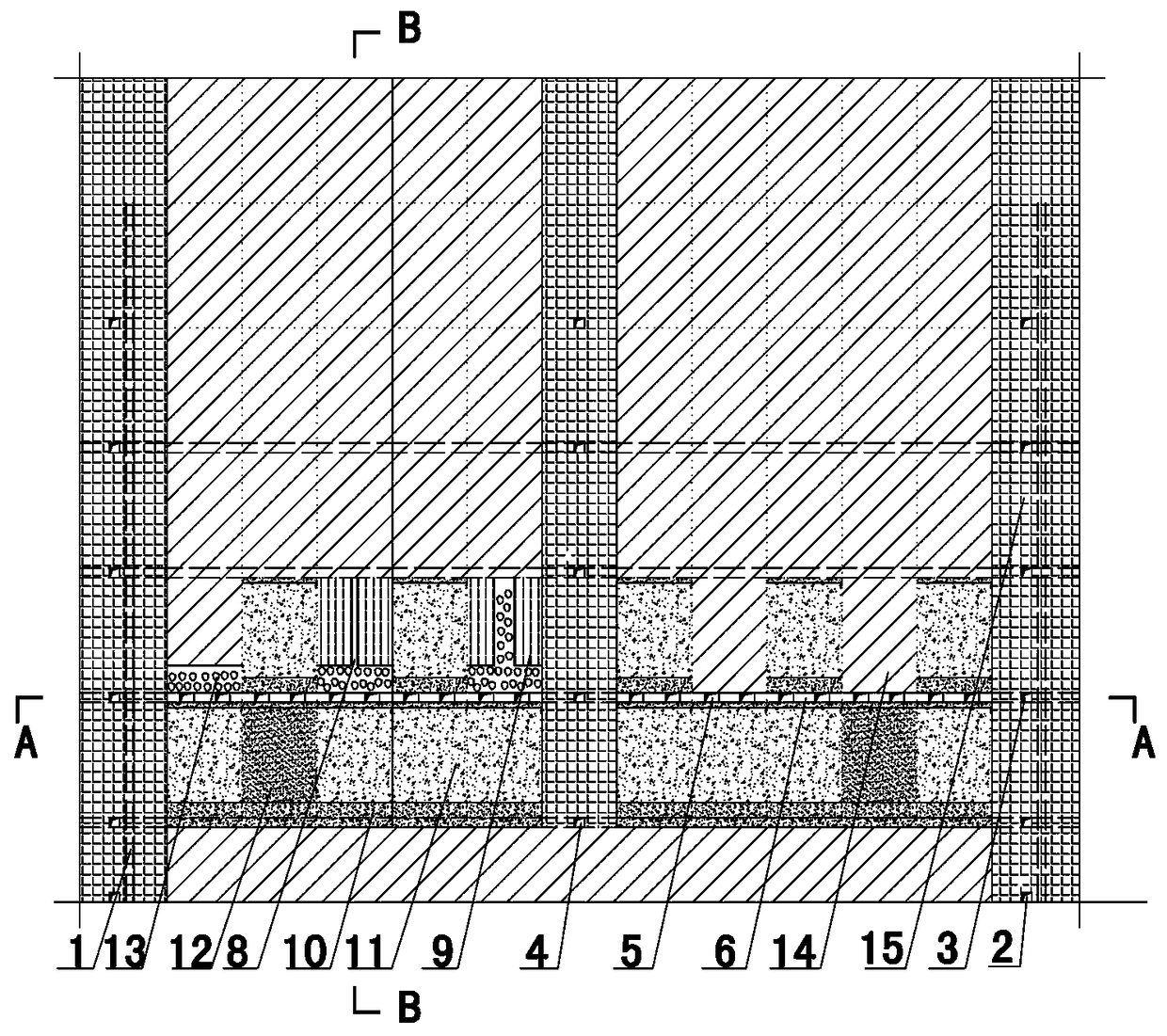

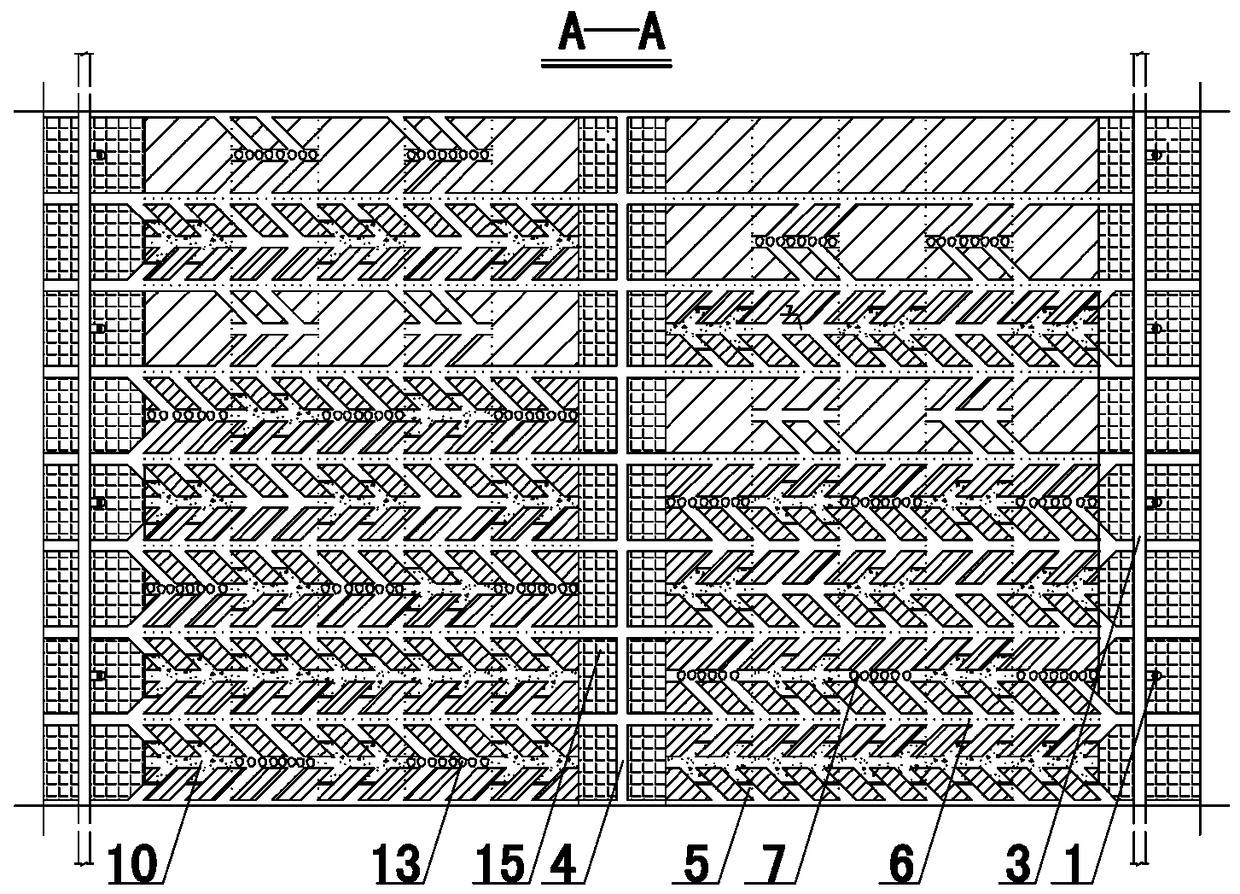

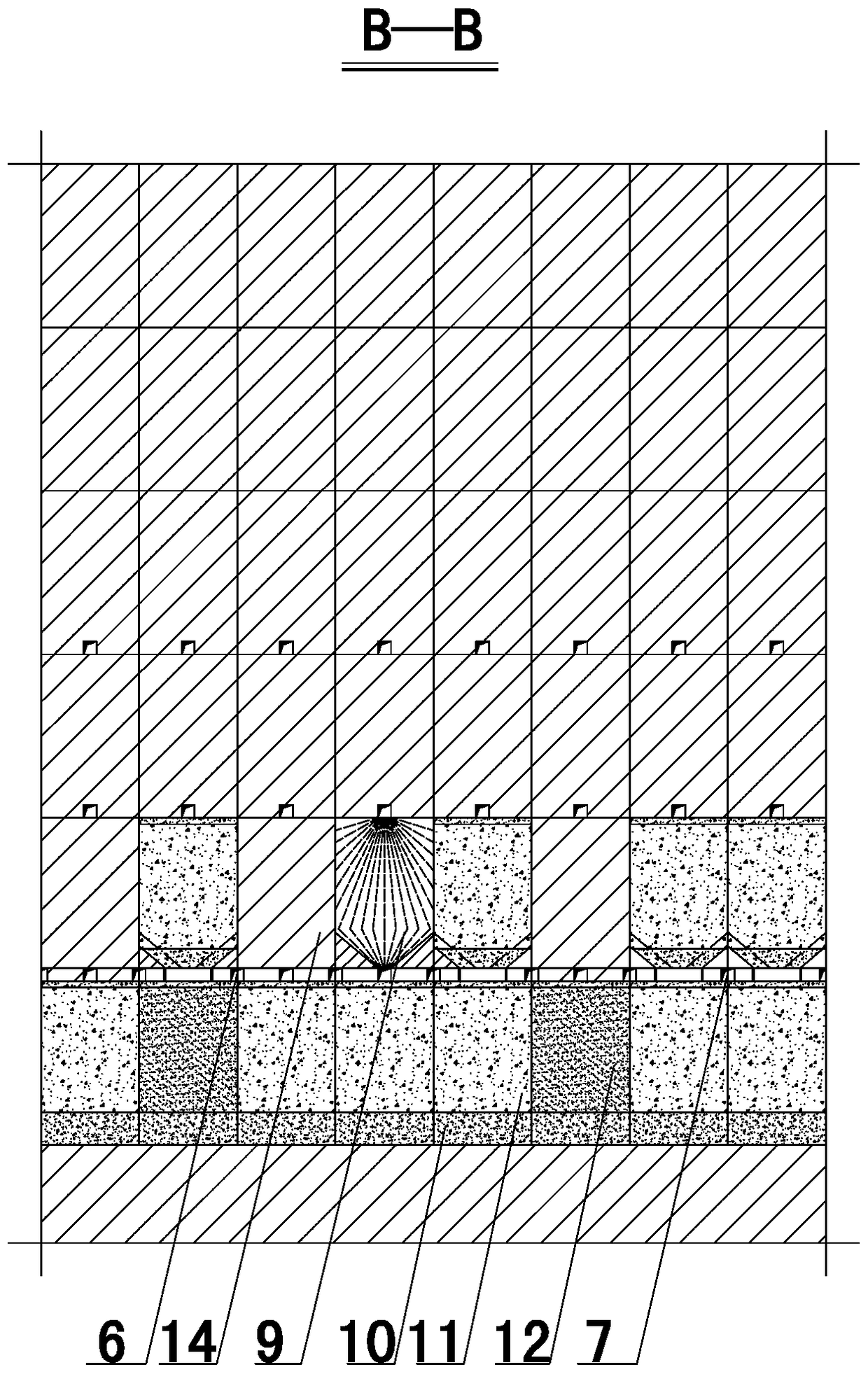

[0030] The present invention will be further described below in conjunction with accompanying drawing.

[0031] Such as Figure 1-Figure 3 As shown, a kind of extremely thick large ore body stage emptying and subsequent filling mining method of the present invention is characterized in that the horizontal plane of the stope adopts a square arrangement to control the exposed area of the side of the stope, and includes the following steps:

[0032] 1) Panel layout

[0033] The panels are divided along the ore body trend, and each panel is composed of multiple stopes 14, each panel is 215m long, 150m wide, and 50m high; each panel is composed of 25 stopes, and each stope is 14 long 30m, 30m wide, and 50m high; perpendicular to the direction of the ore body, there are ore pillars 14 on both sides of the panel, one with a 30m ore pillar 15, and a return airway 4 inside the 30m ore pillar 15; The 35m ore pillar 15 is provided with an air intake lane 3 and an ore chute 1 in the 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com