Equipment for achieving regional sintering

A technology of regional sintering and equipment, applied in the field of sintering, to achieve the effects of controlling deformation and collapse, reducing costs and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

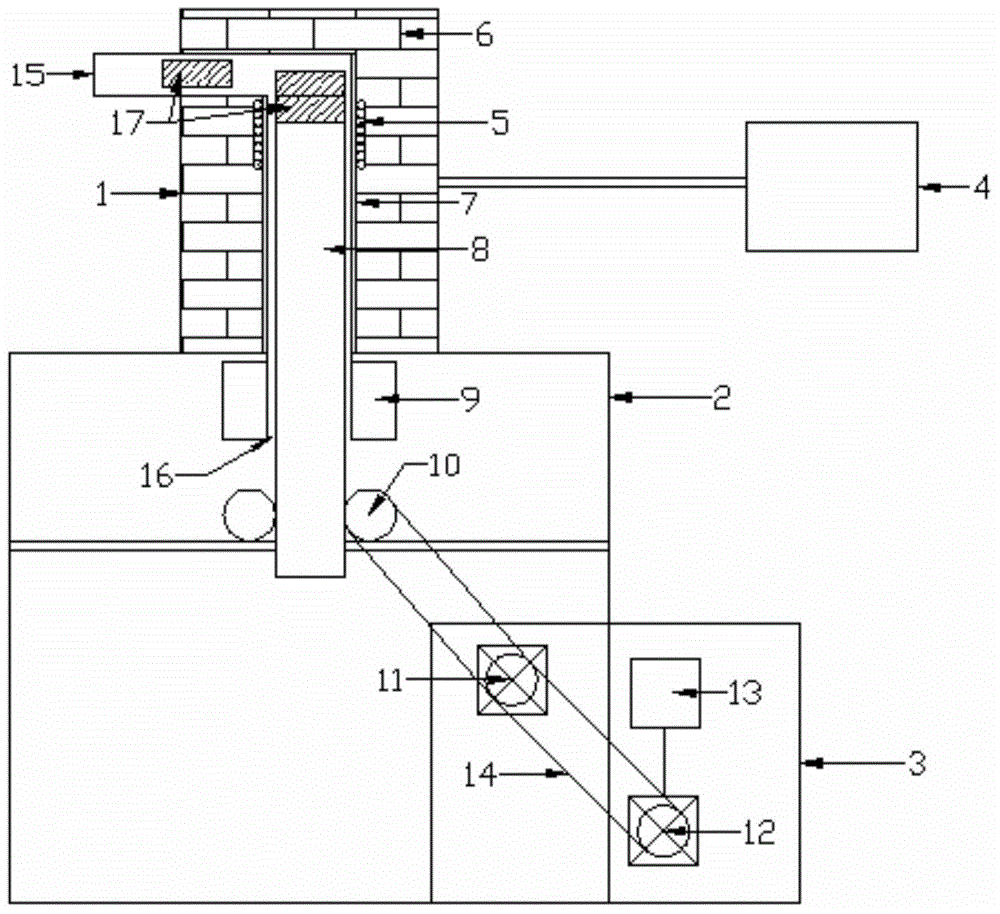

[0018] Aiming at the above-mentioned problems existing in the prior art, the present invention proposes a device for realizing zone sintering by referring to the zone smelting technology, which can use the zone sintering method to prepare one-dimensional large-size products, that is, the one-dimensional large-size green body is processed in the billet making process Segmentation is pressed into individual sheets, and then the sheets are stacked and area sintered.

[0019] figure 1 It is a device for realizing zone sintering according to an embodiment of the present invention.

[0020] Such as figure 1 As shown, the equipment for realizing regional sintering according to the embodiment of the present invention includes: a regional sintering furnace and a mechanical transmission device for realizing the downward movement of the billet.

[0021] Wherein, the regional sintering furnace includes: a furnace shell 1, a furnace mouth 15 arranged on the furnace shell 1 as a feed inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com