High-frequency induction melting type metal 3D (three-dimensional) printing machine

A 3D printer and high-frequency induction technology, applied in the field of metal 3D printers, can solve the problem of not being able to directly form 'ton-level' metal components, and achieve the effect of high-quality metal 3D printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Each part of the high-frequency induction fusion direct manufacturing printer HFDM of the present invention will be described separately.

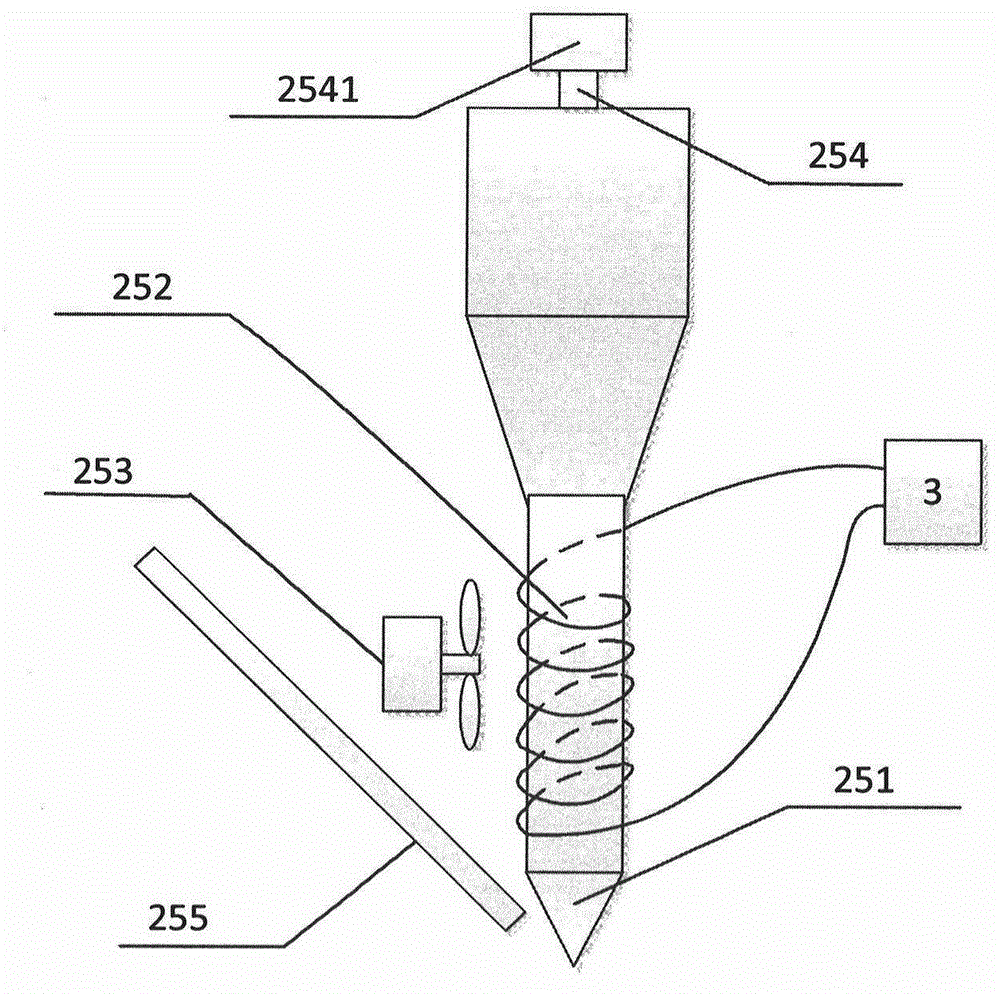

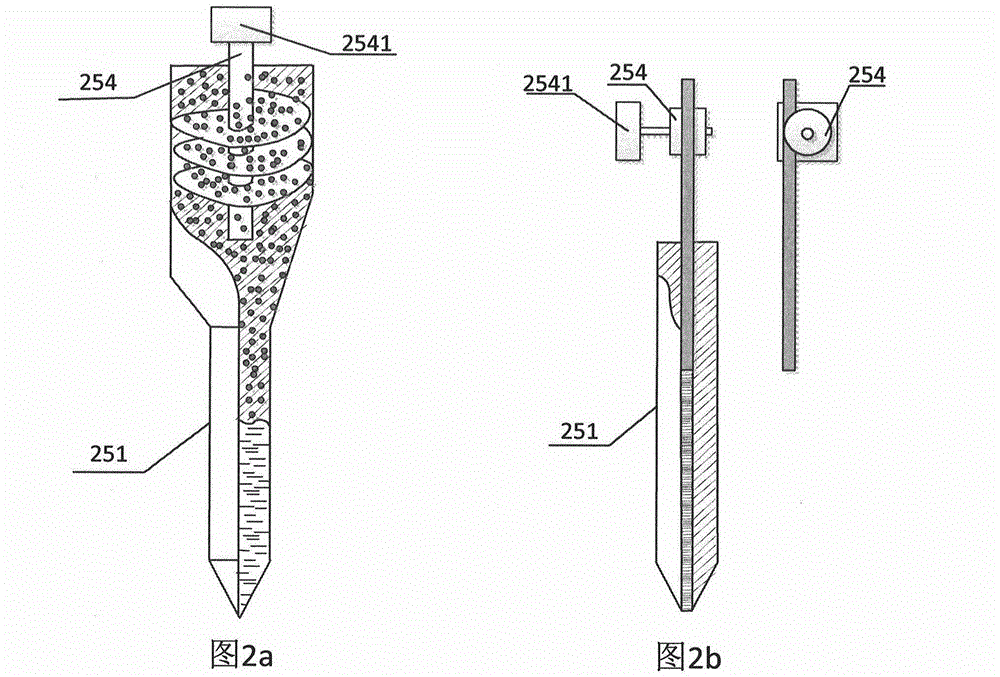

[0046] HFDM is composed of control computer 1, high-frequency induction melting 3D printing box frame 2, melting high-frequency signal generator 3, workpiece heating device 4, gas pipeline 5 and power supply 6, etc.

[0047] The control computer 1 is a master-slave computer system. The master computer collects the information of each sensor single-chip microcomputer, and performs synchronous control on each component through each execution single-chip microcomputer to realize the 3D printing function. Due to the powerful functions of the current computer, the support of the cloud computer system, and the intelligence and integration of various sensors and execution components, the control computer 1 is diversified.

[0048] High-frequency induction fusion 3D printing box frame 2 has various implementation methods according to the si...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap