A material receiving system of an automatic sewing machine

A sewing machine and automatic technology, which is applied in the direction of sewing machine components, sewing equipment, clothing piece collection device, etc., can solve the problems of low automation and achieve the effect of stable material receiving, neat stacking and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

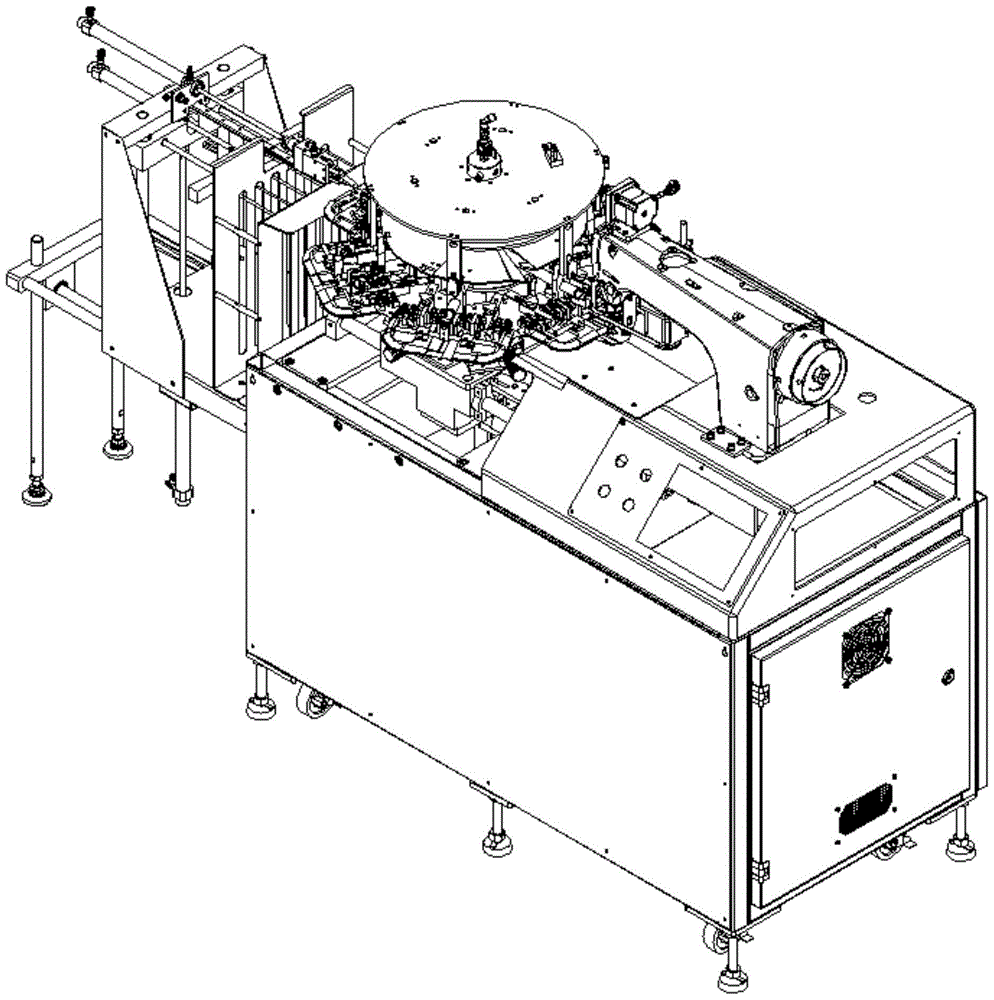

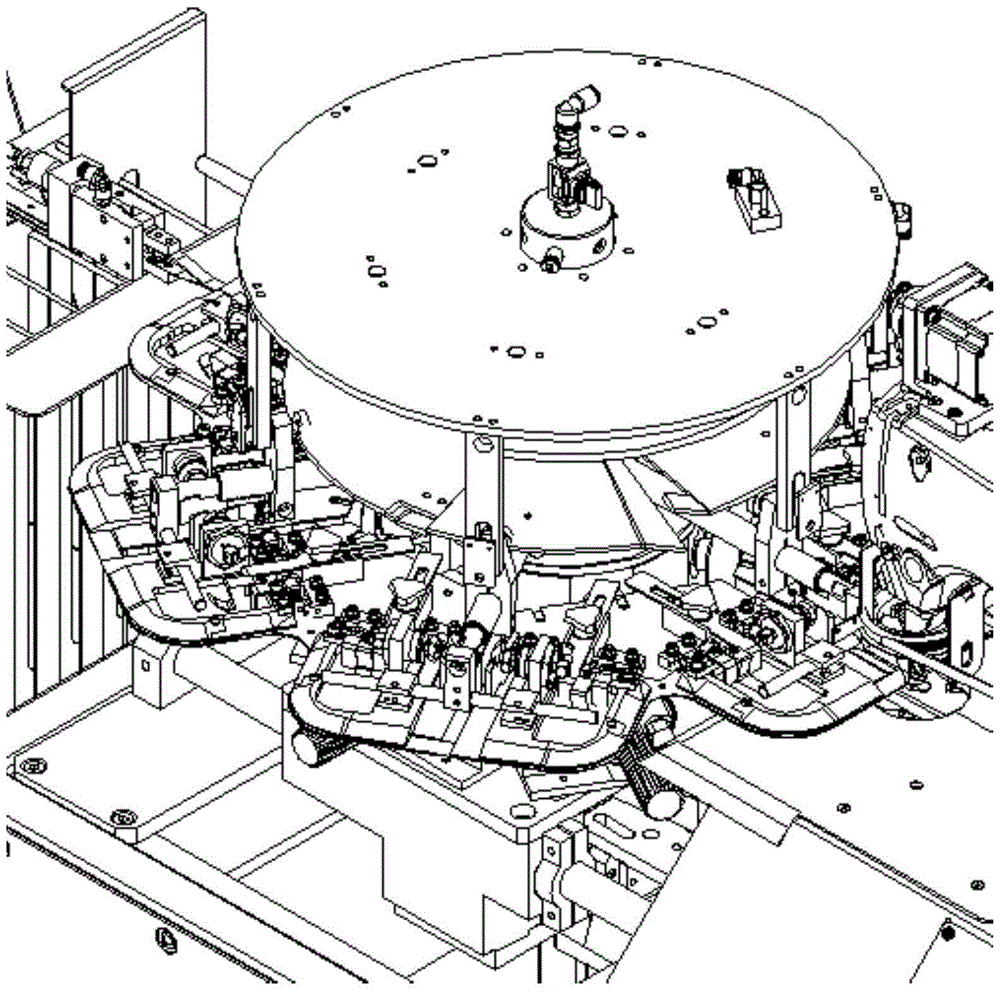

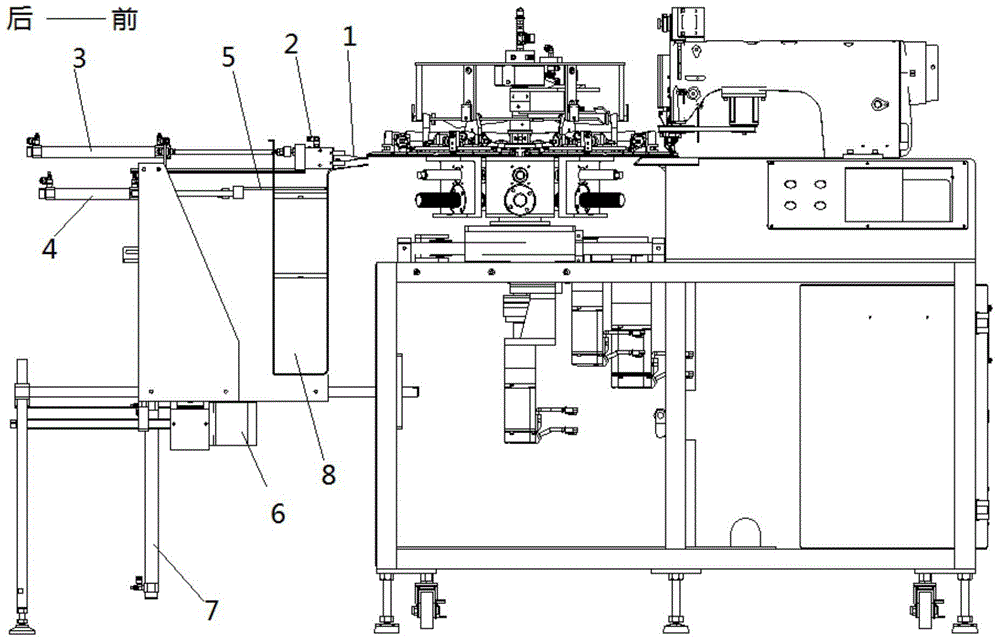

[0025] see Figure 1-7 , a material receiving system of an automatic sewing machine, the automatic sewing machine includes a loading turntable, and a plurality of sewing stations are evenly distributed around the circumference of the loading turntable; the loading turntable is driven by a horizontal feeding servo motor 11 to move left and right as a whole, Driven by the disk rotation servo motor 13 to rotate, and driven by the variable-mode servo motor 12 to perform variable-mode expansion and contraction; the receiving system is driven by the servo-motor 6 to move forward and backward in conjunction with the size of the loading turntable; The discharge station of the loading turntable is correspondingly equipped with a receiving folder 1, which clamps the sewn product under the action of the first cylinder 2, and shrinks backward to the full s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com