Reed tooth of hosiery stitching machine

一种缝袜机、针板的技术,应用在缝纫机元件、缝纫机用壳体、针织等方向,能够解决易磨伤线圈、线圈磨擦、截面积大等问题,达到容易套接、提高顺畅度、稳定嵌接的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

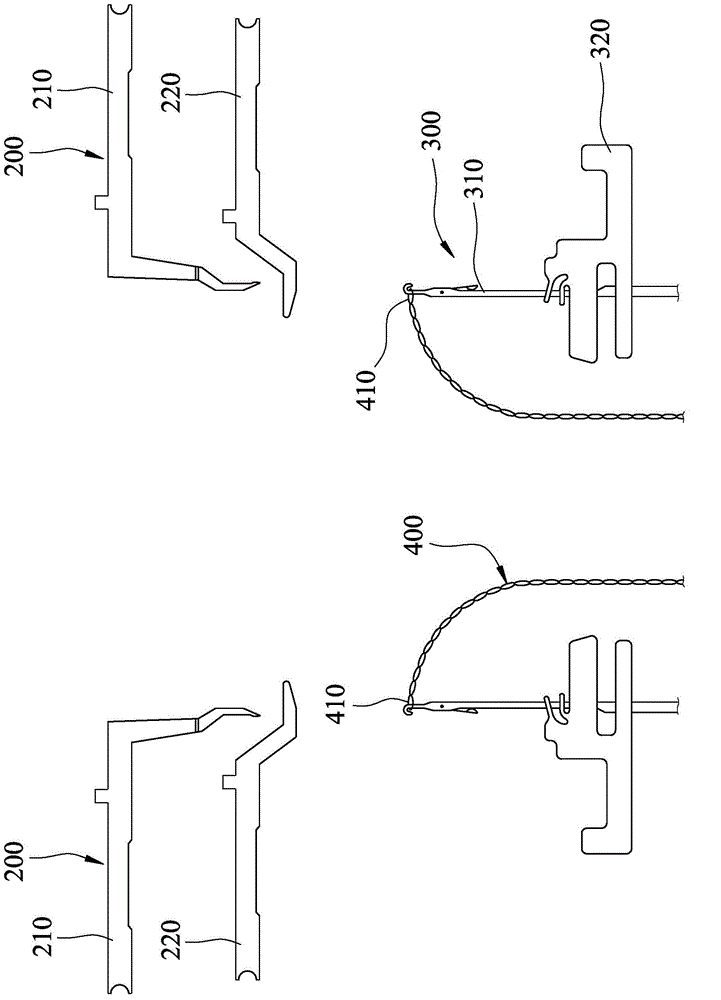

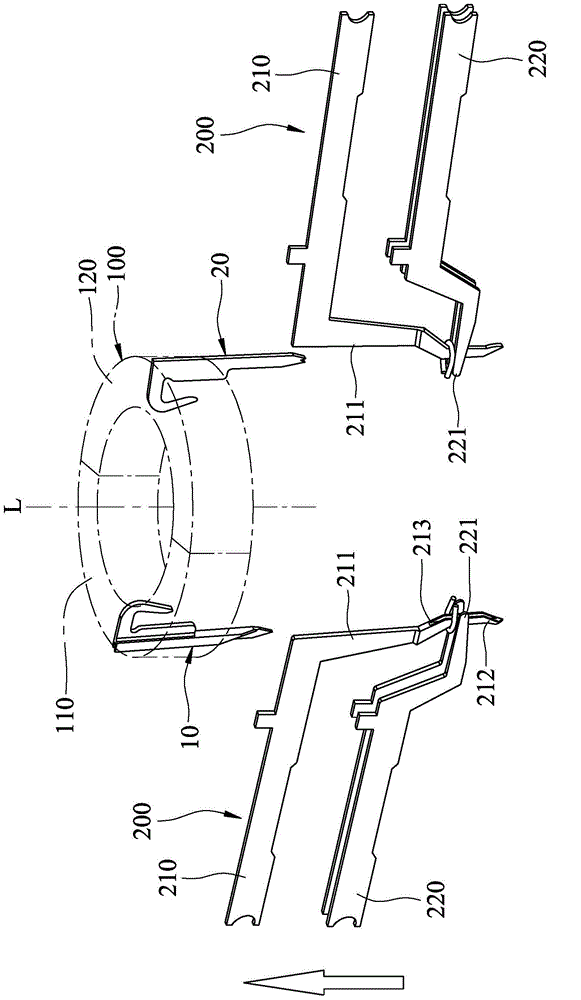

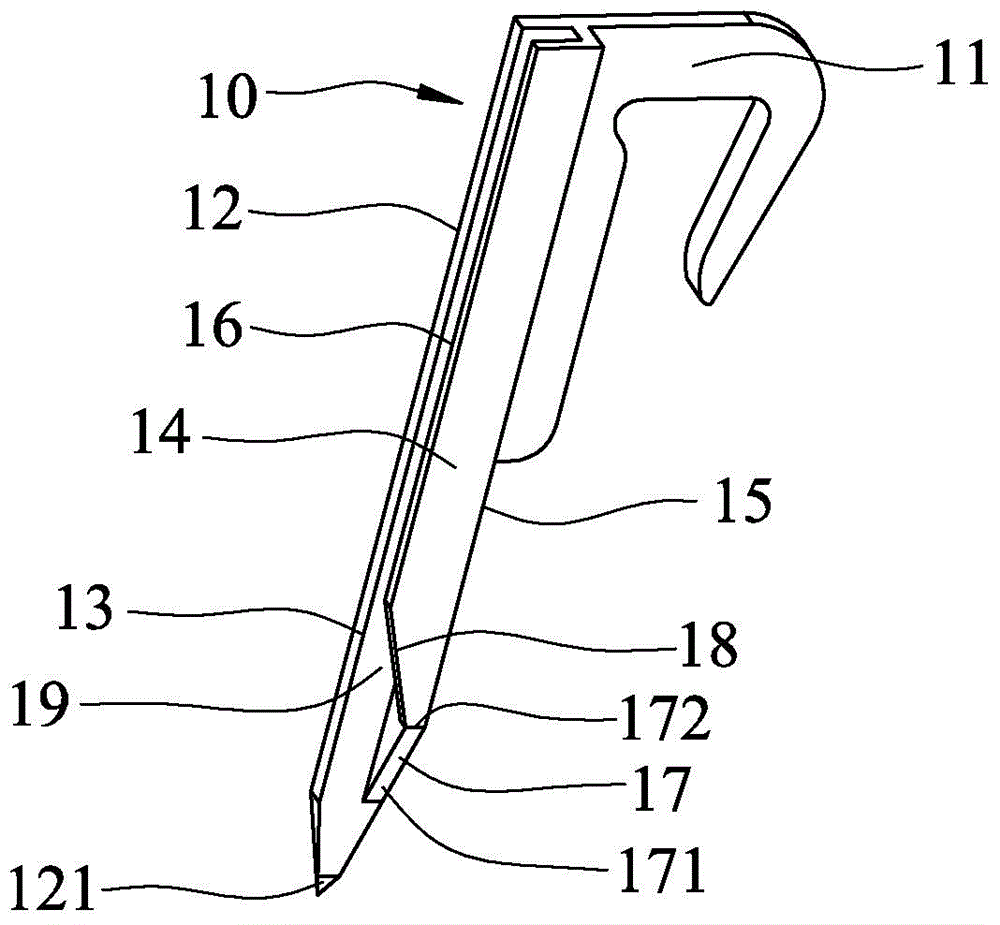

[0028] refer to figure 1 and figure 2 , a preferred embodiment of the needle plate 10 of the sock sewing machine of the present invention can cooperate with several movable needle plates 20 to be respectively installed on a fixed reed 110 and a movable reed 120 of a sock opening sewing device 100, and can be matched again A sock body transfer unit 200 transfers several coils 410 of a sock opening of a hollow tubular sock body 400 woven by a hosiery machine 300, and then utilizes a sewing needle 500 (see Figure 14 ) for sewing, the sock knitting machine 300 includes several knitting needles 310 and several sinkers 320, when the sock body 400 is finished weaving by the sock knitting machine 300, the loop 410 is hooked on the knitting needles 310. The number of needle plates 10 installed in the fixed reed 110 is the same as that of the movable needle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com