Box culvert advancing construction method for building new frame bridge above existing subway structure

A technology with existing subway and construction methods, applied in the erection/assembly of bridges, buildings, bridges, etc., it can solve the problems of train speed limit or outage of rail traffic, shortened train running interval, floating deformation of the soil below, etc. The effect of restraining floating deformation, improving economic and social benefits, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

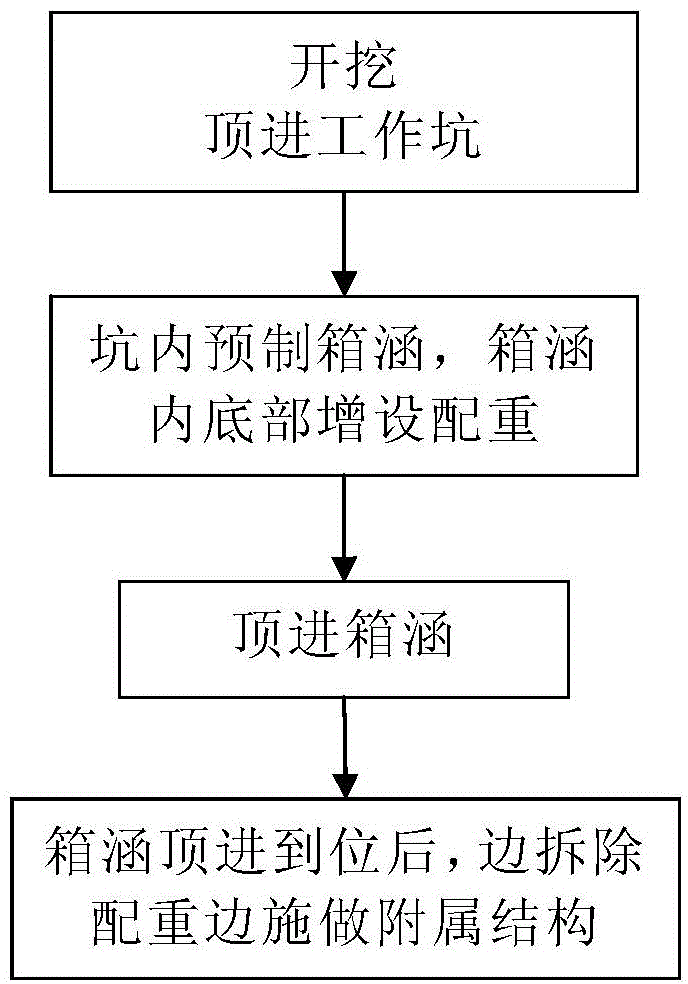

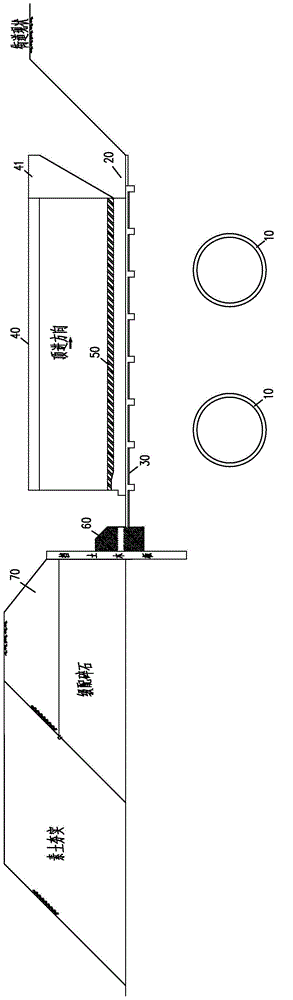

[0021] Such as figure 1 As shown, the new frame bridge of the present invention wears the existing subway structure box culvert jacking construction method and comprises the following steps:

[0022] Step 1: Excavate the jacking pit on one side of the proposed frame bridge above the existing subway structure;

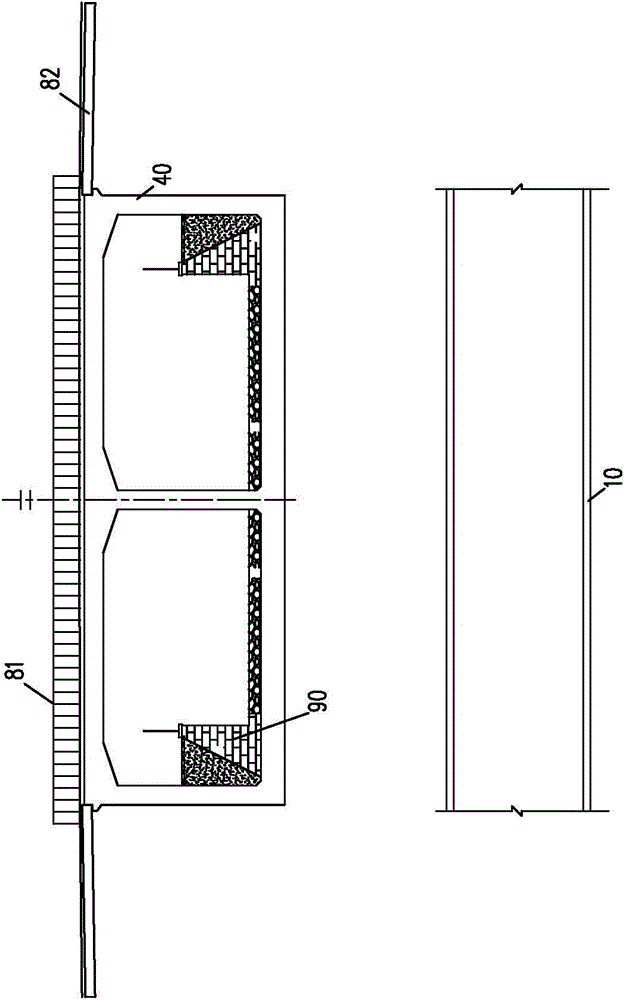

[0023] Step 2: Prefabricate a box culvert in the jacking pit, add a counterweight to the bottom of the box culvert, and the sum of the weight of the counterweight and the weight of the box culvert is equal to the weight of the excavated soil (referring to the weight of the excavated soil during the entire construction period). The total weight of the soil excavated during the process) to make up for the weight of the soil lost during the excavation and jacking into the work pit;

[0024] Step 3: Jacking the box culvert, wherein: in the process of jacking the box culvert, gradually expand the soil mass in the jacking direction (referring to the direction of jacking the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com