Multistage resistance-increasing anchor rod and construction method

An anchor rod and rod body technology, which is used in the installation of anchor rods, earthwork drilling, infrastructure engineering, etc., can solve the problems of complex procedures and high costs, and achieve the effect of simple components, simple stress application, and rapid mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

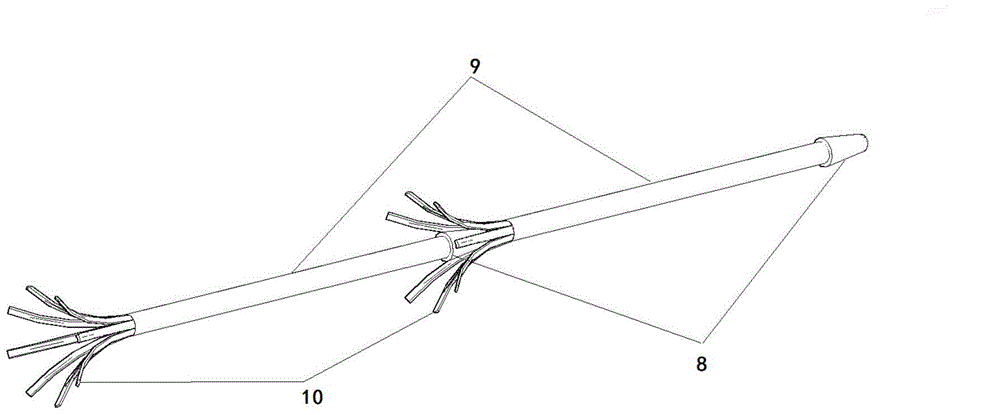

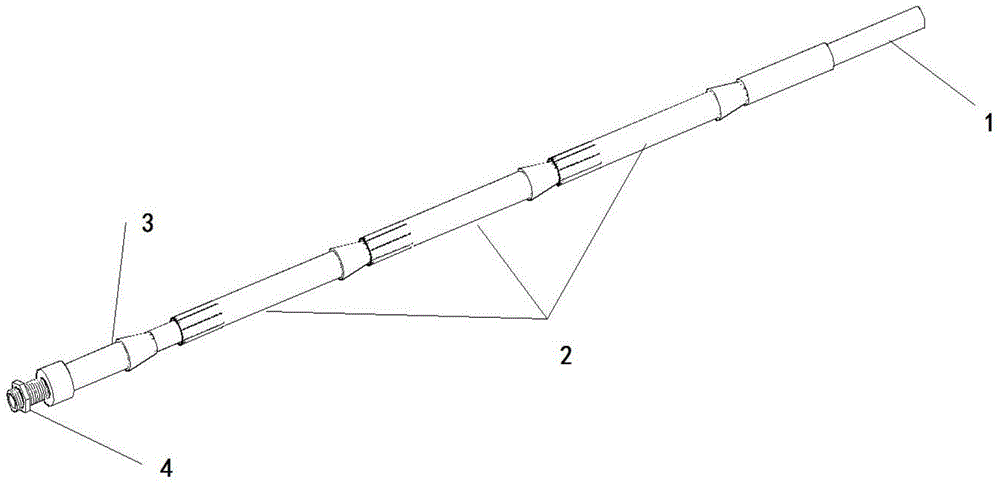

[0028] Such as figure 1 As shown, the multi-stage resistance-increasing bolt includes a rod body 1, a plurality of self-expanding devices 2 sequentially nested and installed outside the rod body 1, a jacking rod 3 and a fixed structure 4, and the self-expanding device 2 and the jacking rod 3 can be Sliding freely in the middle and rear of the rod body 1. The automatic expansion of the self-expanding device 2 is realized through the pushing of the jacking rod 3 and the blocking and extrusion of the rod body stop block 5, and the permanent fixation of the rod body in an increased resistance state is realized by fixing the position of the jacking rod 3 through the fixing device 4.

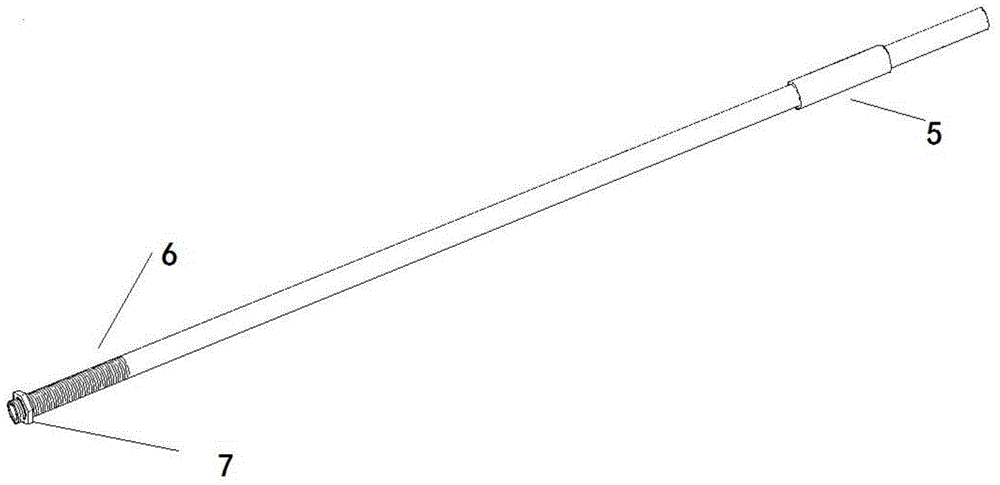

[0029] Such as figure 2 As shown, the rod body 1 is of solid structure, with a rod body stopper 5 provided at the front end, and a screw thread 6 provided at the rear end. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com