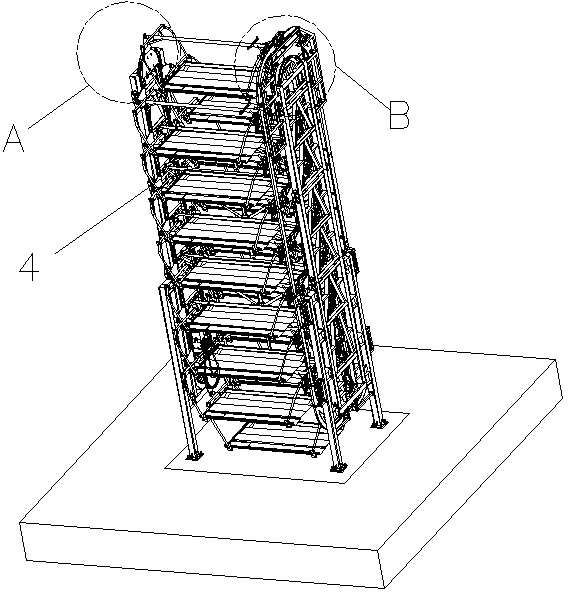

Chain reversing guide rail for combined type vertical circulation stereo garage and preparation method thereof

A vertical circulation, three-dimensional garage technology, which is applied to buildings, coatings, buildings, etc. where cars are parked, can solve the problems of particularly severe impact on the reversing guide rails, the radial outer peripheral surface is not wear-resistant, and the safe operation of the garage is difficult. The effect of prolonging the service life, low processing and manufacturing cost, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

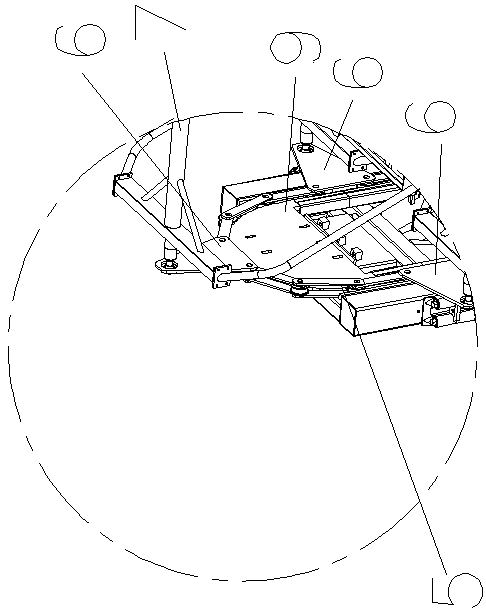

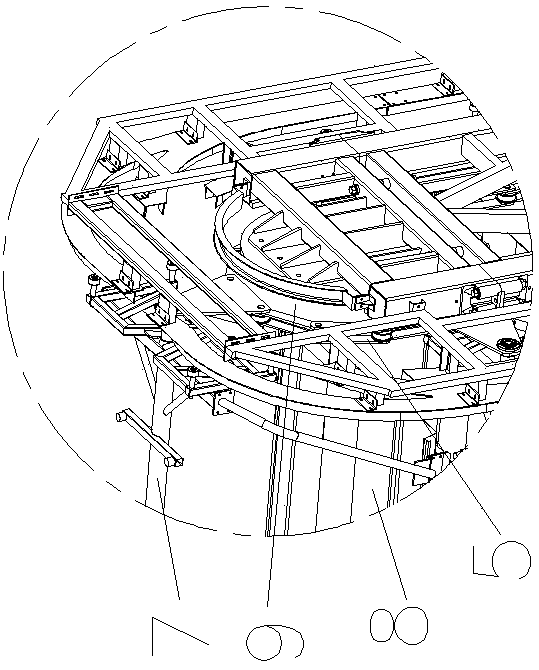

[0040] Example 1. Such as Figure 4-8 As shown, a combined vertical circulation three-dimensional garage chain reversing guide rail includes a base 1 made of steel with a semicircular longitudinal section, the radial outer peripheral surface 12 of the base is an arc surface with an opening downward, and the base A number of wear-resistant arc-shaped blocks 2 are arranged in sequence on the radially outer peripheral surface 12 of each wear-resistant arc-shaped block 2 and the base 1 is movably connected, and the radially outer peripheral surfaces of each wear-resistant arc-shaped block 2 are in the same arc surface and The radially outer peripheral surfaces of each arc-shaped block combine to form a smooth radially arc-shaped outer peripheral surface of the chain reversing guide rail.

[0041] Each wear-resistant arc block 2 is connected with the base 1 by screws.

[0042] The base 1 is provided with several base screw holes 11, and the radially inner peripheral surface of ea...

Embodiment 2

[0063] Example 2. The difference between this embodiment and Embodiment 1 is that the wear-resistant arc-shaped block 2 adjacent to the stopper 13 is made of impact-resistant and wear-resistant alloy steel, that is, the wear-resistant arc-shaped block 2 adjacent to the stopper 13 The wear-resistant arc-shaped block 2 made of chromium alloy steel or manganese alloy steel solves the problem of the radial outer circumference of the reversing guide rail when the car chain plate on the chain 5 will leave the radial outer peripheral surface of the reversing guide rail in the prior art. Severe problem with low impact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com