Butterfly valve system adjusting via exhausting pressure

A technology of exhaust pressure and butterfly valve, applied in the direction of charging system, exhaust gas recirculation, adding non-fuel substances to fuel, etc., can solve problems such as complex control system, and achieve the effect of reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

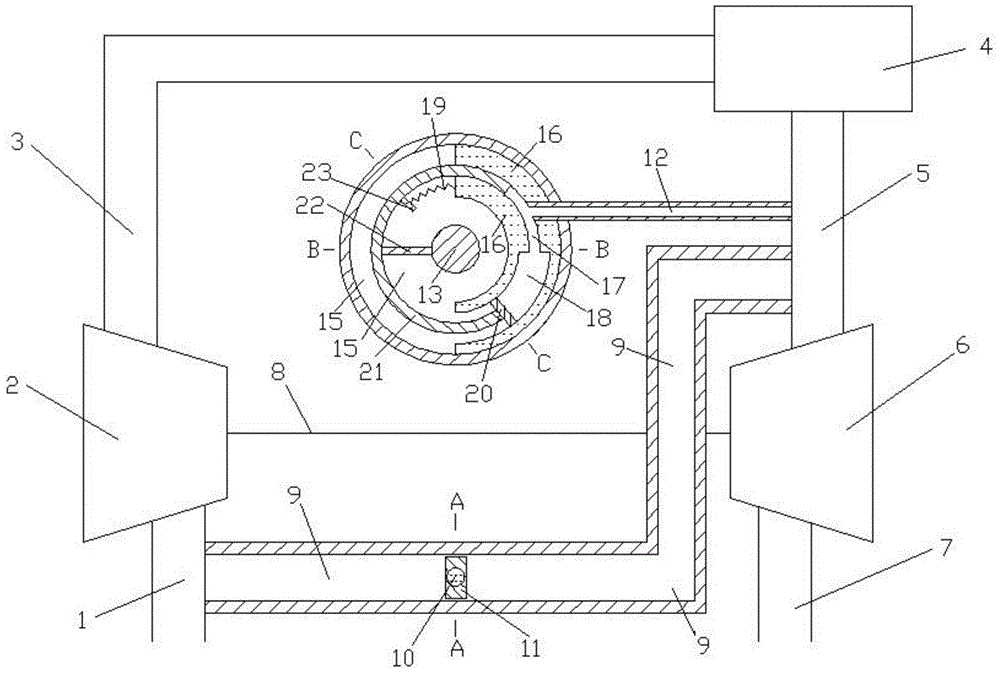

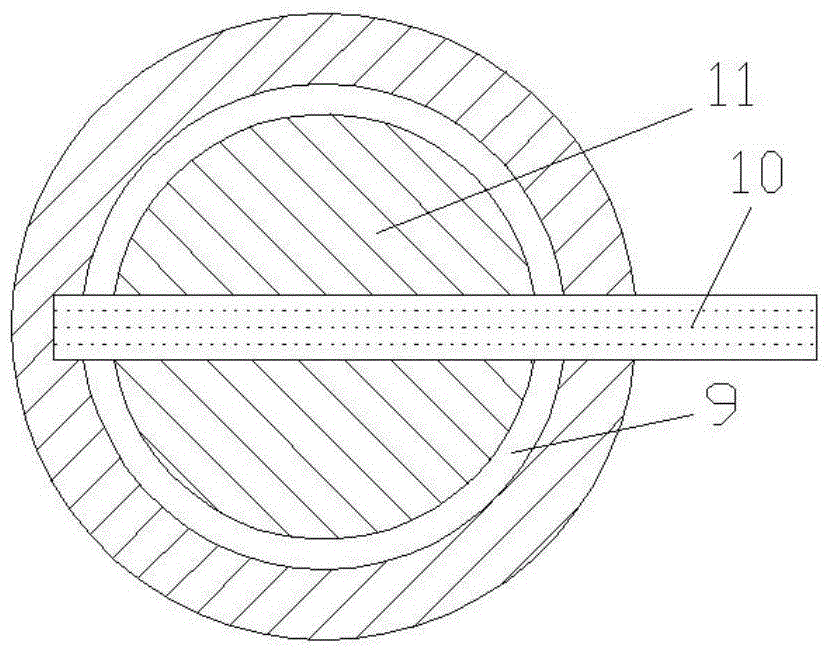

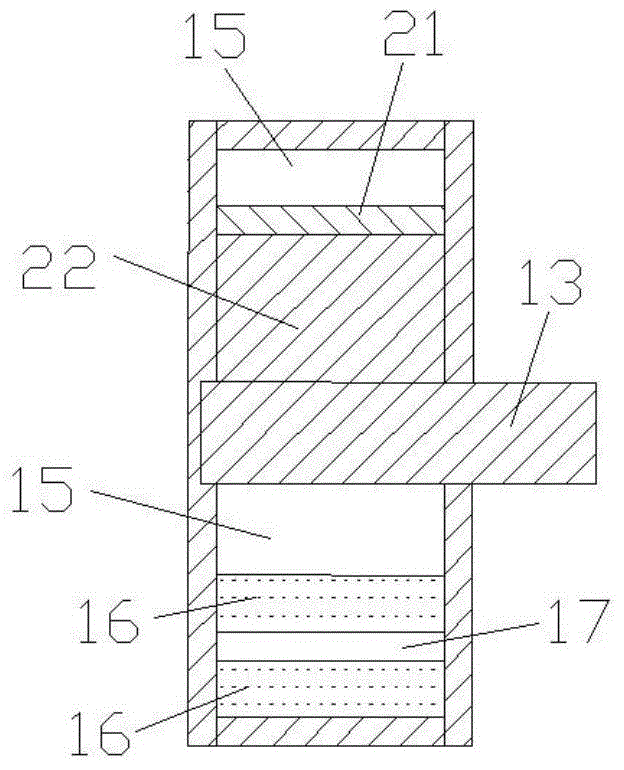

[0017] like Figure 1 to Figure 5 As shown, the present invention includes a compressor intake pipe 1, a compressor 2, an engine intake pipe 3, an engine 4, an engine exhaust pipe 5, a turbine 6, a turbine exhaust pipe 7, a connecting shaft 8, a first connecting pipe 9, A rotating shaft 10, a butterfly valve 11, a second connecting pipe 12, a second rotating shaft 13, a chain 14, a volume chamber 15, a fixed body 16, a first through-pipe 17, a second through-pipe 18, an elastic member 19, a partition 20 , rotating body 21, connecting plate 22 and fixing plate 23, the air inlet and outlet of the compressor 2 are respectively connected with the air outlet of the compressor air inlet pipe 1 and the air inlet of the engine air inlet pipe 3, and the air inlet and outlet of the engine 4 are respectively connected with the engine inlet and outlet. The air outlet of the air pipe 3 and the air inlet of the engine exhaust pipe 5 are connected, the air inlet and outlet of the turbine 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com