Aerodynamic Air Bearings

An air bearing and gas power technology, which is applied in the field of turbine shafts, can solve the problems of screw box hole wear, screw and bearing box loose connection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

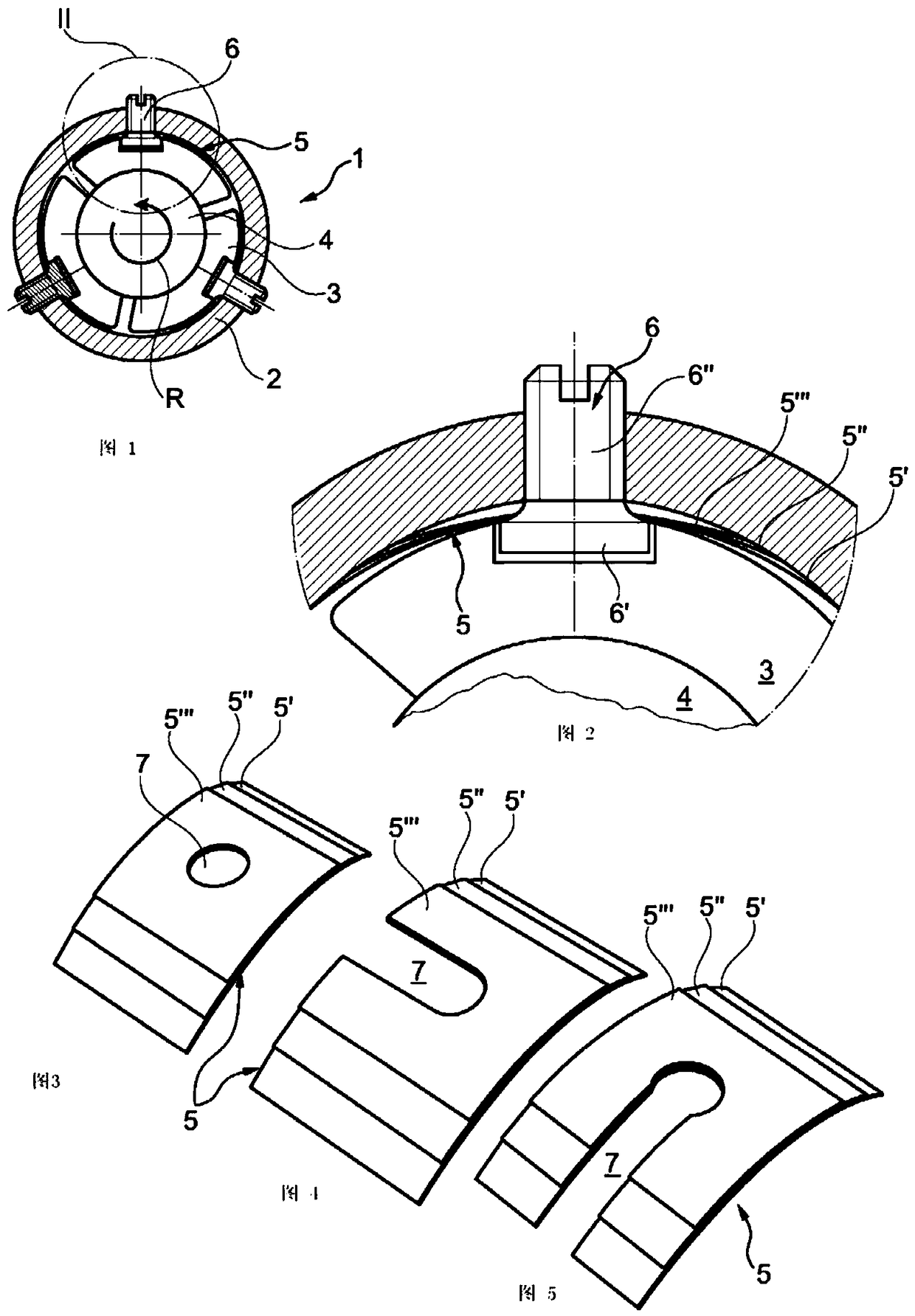

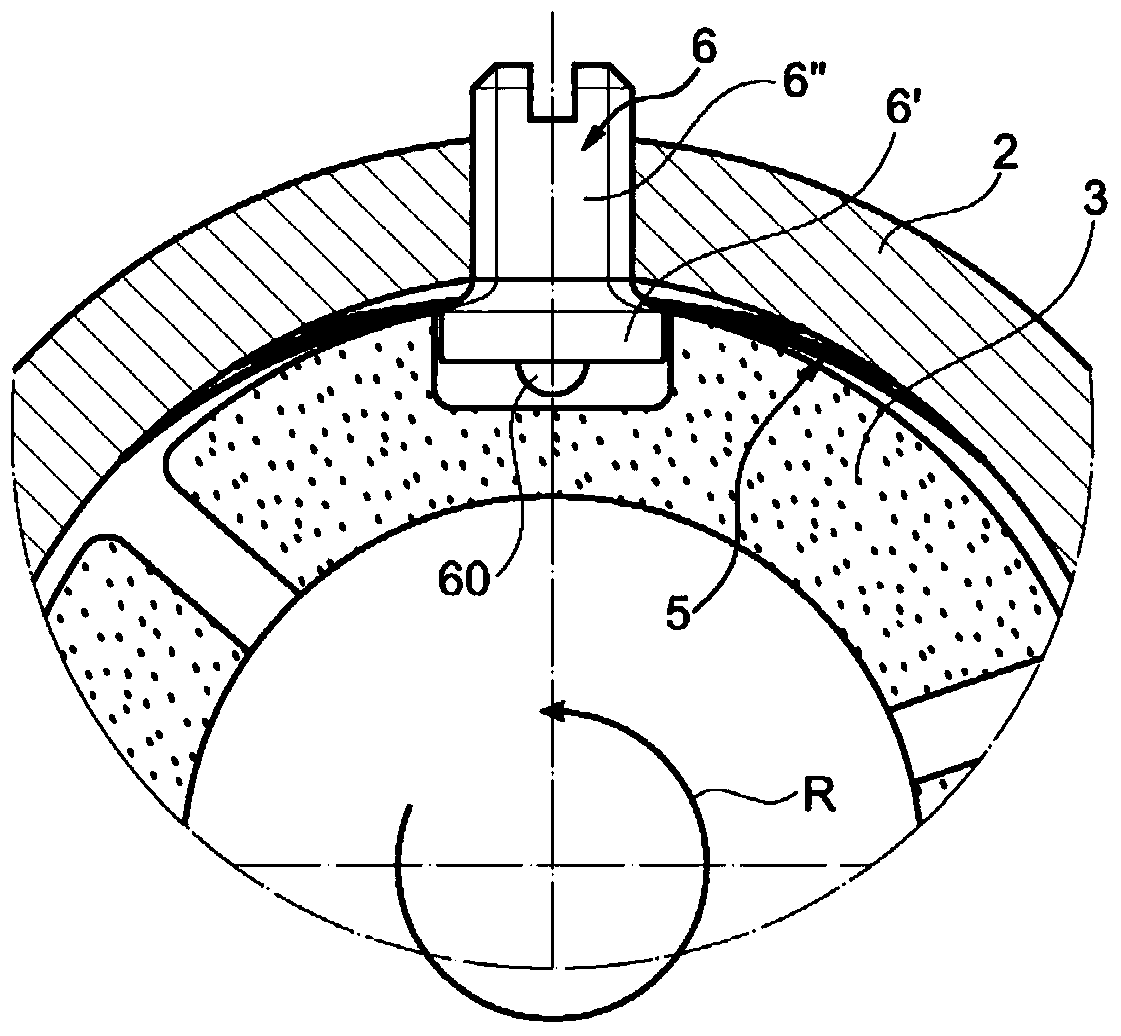

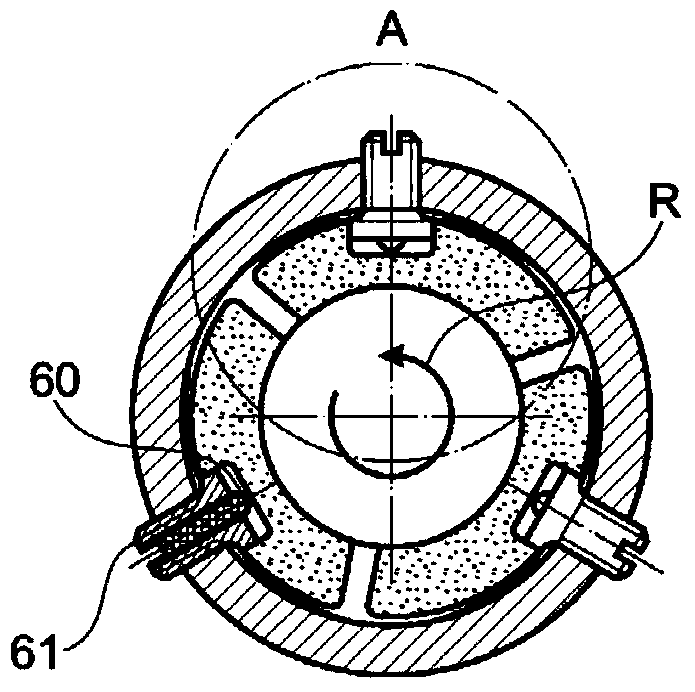

[0022] according to figure 1 , the air bearing 1 comprises a bearing housing 2 having in particular a circular recess in which at least three bushings 3 are arranged which together surround and fit a shaft 4 . Between the inner circumference of the recess of the bearing housing 2 and the opposite outer side of each bushing 3, a retaining spring arrangement in the form of a leaf spring 5 is arranged, which is tensioned with its longitudinal ends against the bearing housing 2 The inner circumference of the central recess, and in the direction of the opposite outer side of the corresponding bearing 3, is tensioned against with its central region. The sleeve 3 is kept fixed in the bearing axis direction, which is perpendicular to the plane of the drawing, or the axis direction of the central axis of the recess of the bearing housing 2, and the circumferential direction of the shaft 4 passing through the screw 6, which is respectively The head 6' protrudes into a recess on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com