Valve base springback type brake valve

A valve seat and gate valve technology, applied in the field of valve seat rebound gate valve, can solve the problems of water flow boundary layer damage, reduce inlet pressure, uneven valve seat, etc., achieve the effect of reducing flow resistance, ensure inlet pressure, and avoid cavitation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

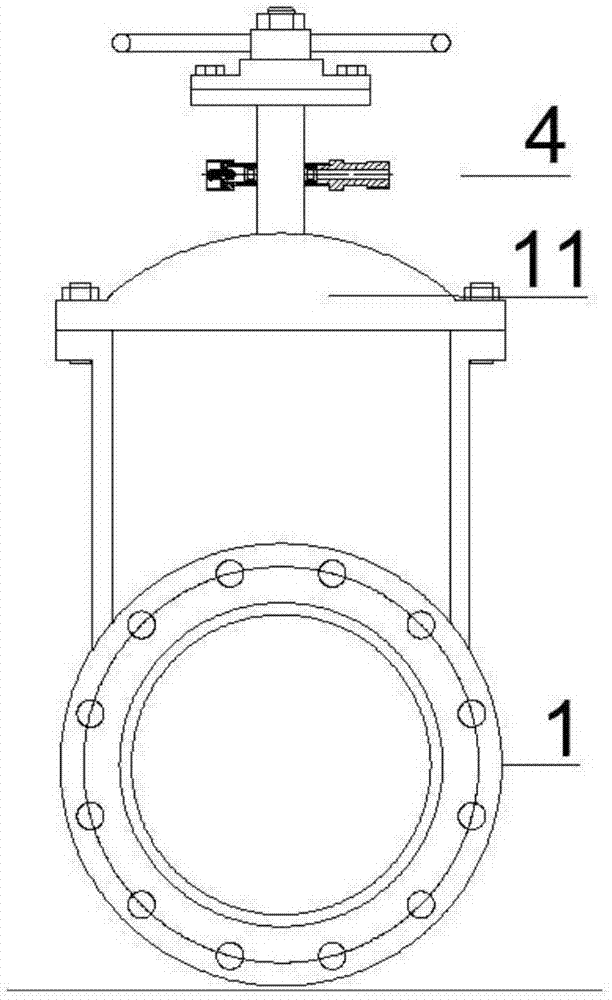

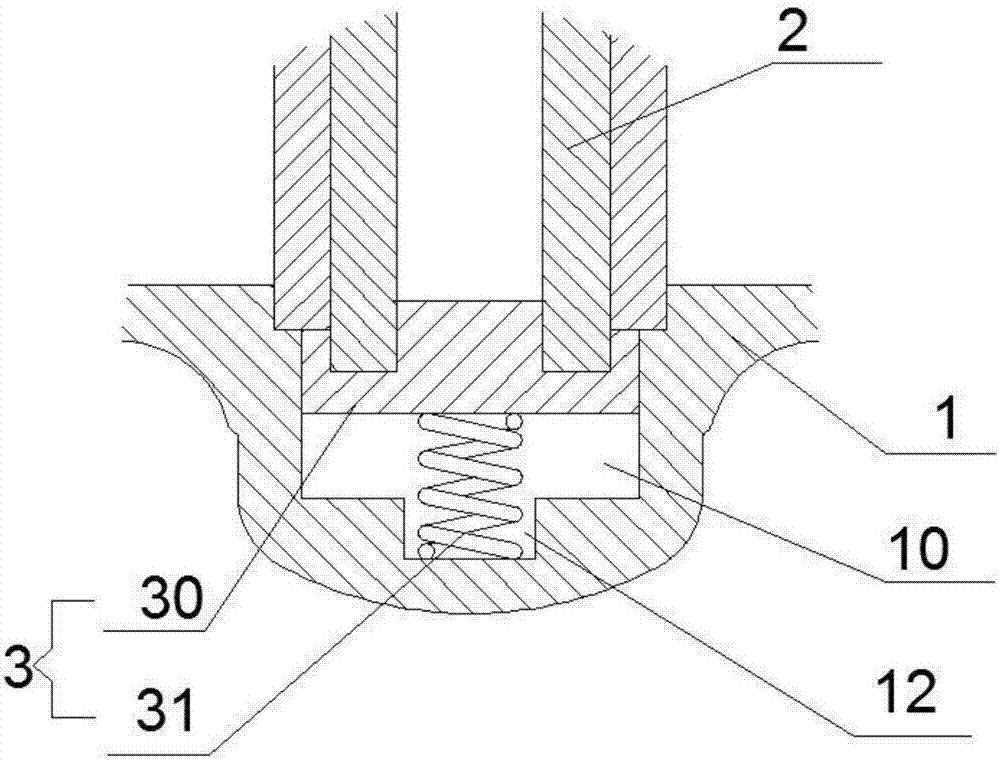

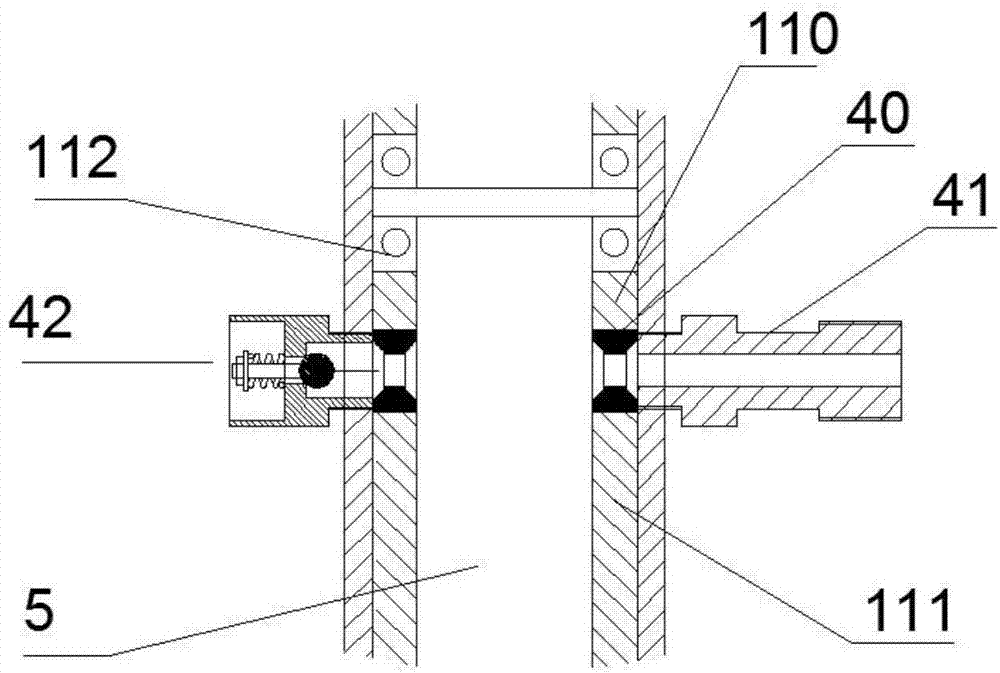

[0036] see figure 1 with figure 2 As shown, the embodiment of the present invention provides a valve seat rebound type gate valve, including: a valve body 1, a gate plate 2 and a rebound type valve seat assembly 3, and the bottom of the inner cavity of the valve body 1 is provided with a first groove 10 , the valve body 1 is connected with a valve cover 11, the valve cover 11 can adopt an inverted T shape, the valve cover 11 is set on the valve body 1 and fixed with bolts to form a gate valve, in order to reduce the size of the valve body , the present invention adopts the concealed rod plate structure gate valve, the main channel adopts a circular structure, the gate valve is made of forgings, and the dimensions in each direction can be reduced to 50%-80% of the equivalent diameter of the standard valve. The gate 2 can adopt a flat structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com