Full-automatic control chair seat impact resistance test device and test method

A testing device and impact-resistant technology, applied in the direction of impact testing, measuring device, machine/structural component testing, etc., can solve the problem that stability and accuracy cannot be guaranteed, chair model restrictions, and lack of seat back impact resistance testing equipment and other problems, to achieve the effect of accurate and reliable test results, high stability, and high degree of test automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but it is not intended to limit the protection scope of the present invention.

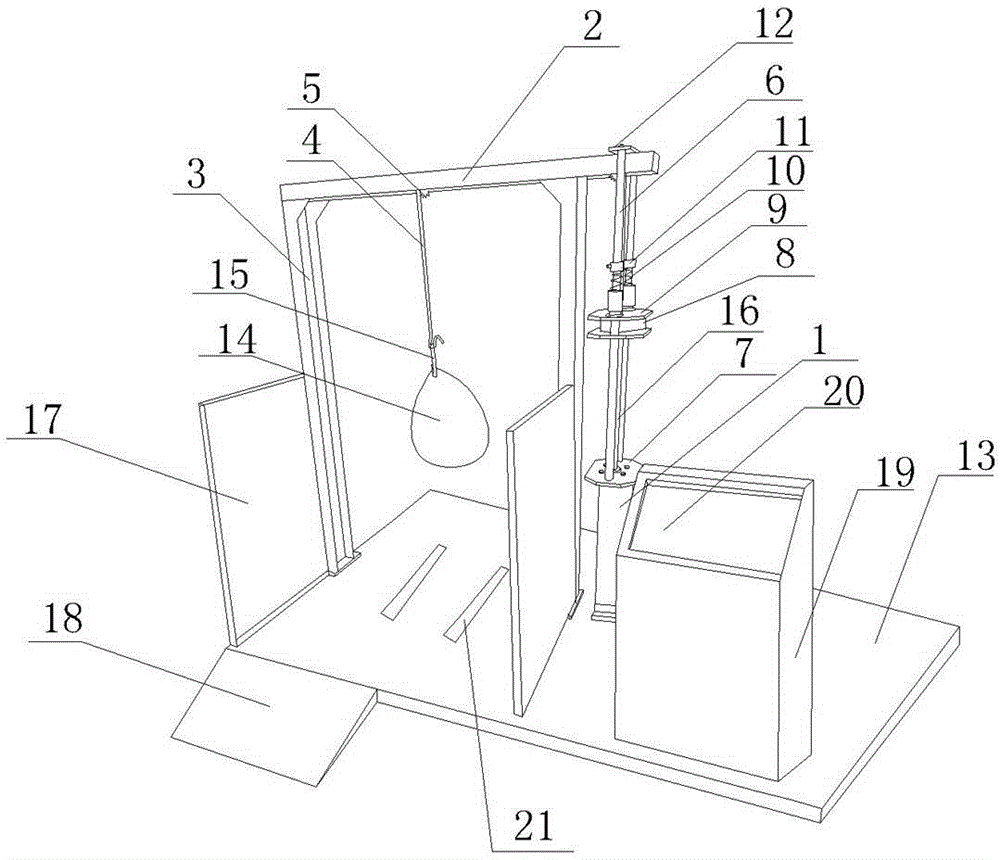

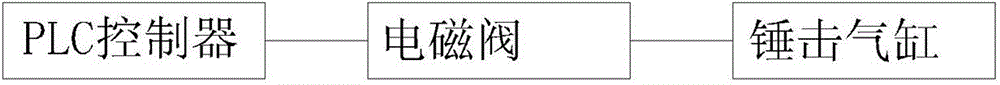

[0035] Such as figure 1 and 2 As shown, a fully automatic control chair seat impact resistance test device includes a base plate 13 and a support bracket arranged on the base plate 13, a hammering mechanism and a control cabinet for controlling the action of the hammering mechanism,

[0036] The support bracket includes two columns 3 and a support beam 2 arranged on the top of the two columns 3, and two sprockets 5 are arranged on the lower side of the support beam 2;

[0037] The hammering mechanism includes a hammering cylinder 1, a counterweight 14 and a hammering chain 4, and the direction of the piston rod 16 of the hammering cylinder 1 is set upward;

[0038] One end of the hammering chain 4 is connected to the piston rod 16 of the hammering cylinder 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com