Drive method and drive IC (integrated circuit) used for LCD (liquid crystal display) panel

A driving method and panel technology, applied to instruments, static indicators, etc., can solve the problems of display color deviation, serious degree, low overall transmittance of liquid crystal modules, etc., and achieve the effect of avoiding display deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings.

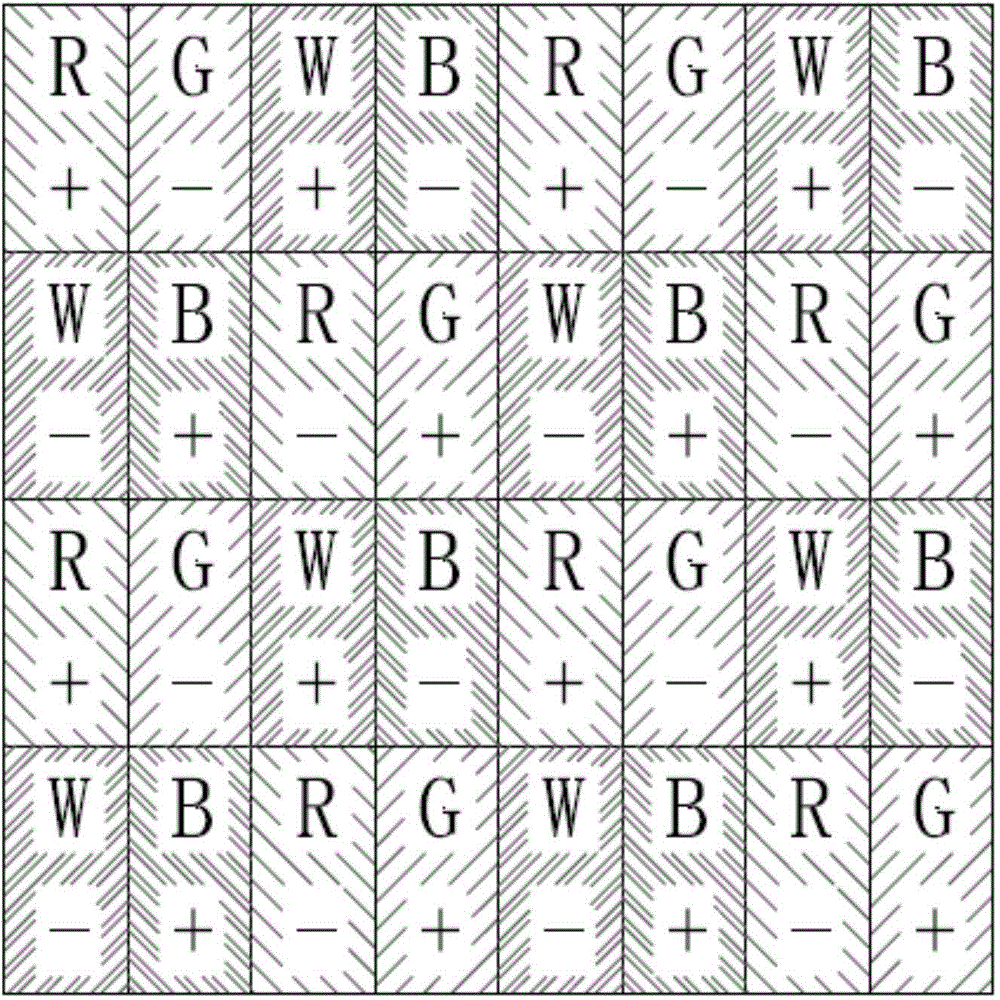

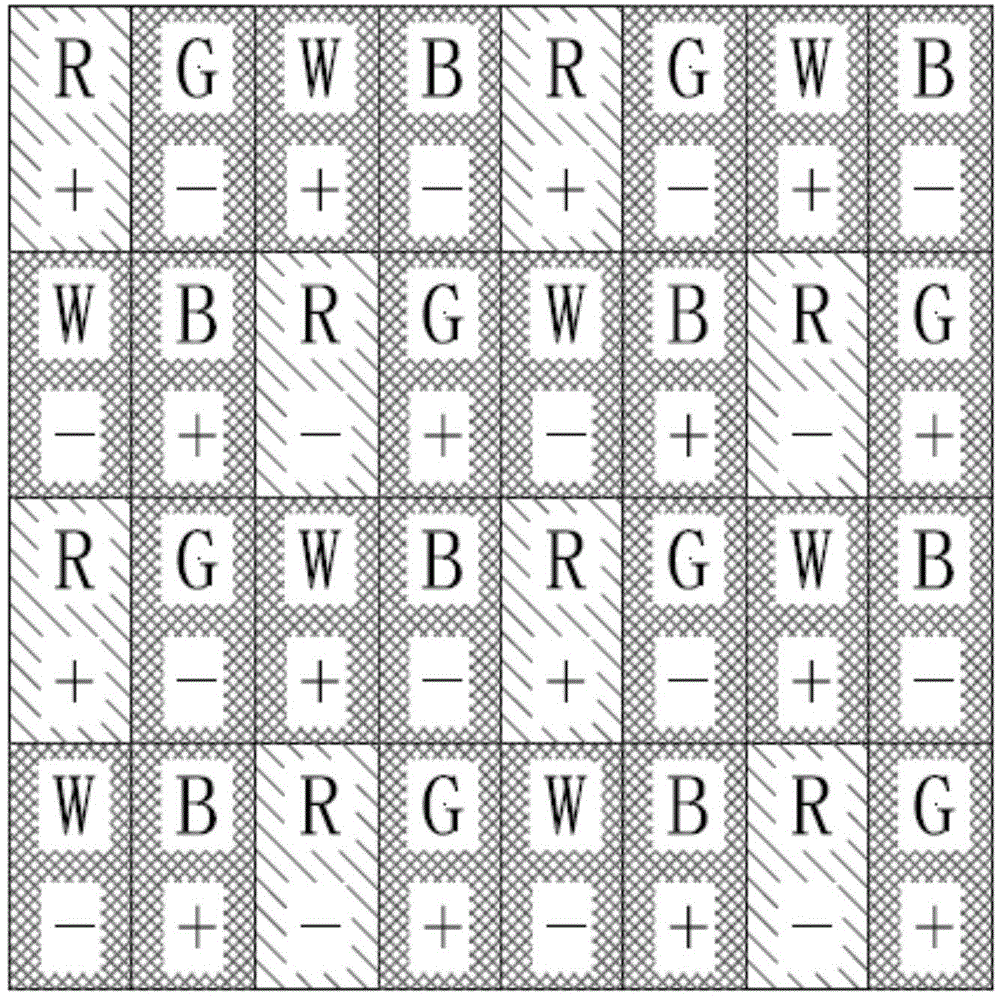

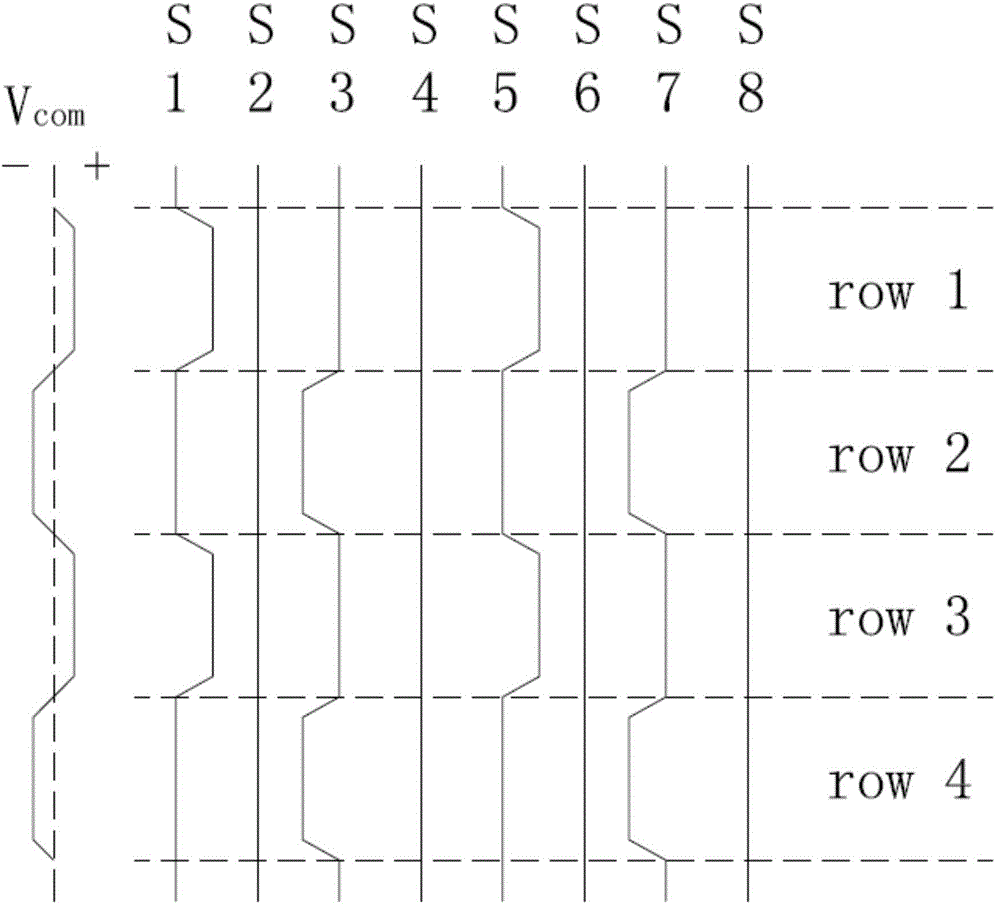

[0056] The present invention is intended to be applied to an LCD panel based on a 2n primary color sub-pixel structure, where n is an integer greater than or equal to 2, that is, the present invention can be applied to an LCD panel based on an even number of primary colors, for example, to an LCD panel based on 4 primary colors , 6 primary colors... LCD panel with sub-pixel structure, its sub-pixel array is M*N. Each pixel is composed of an even number of sub-pixels less than or equal to 2n. For example, for an LCD panel with 4 primary colors, each pixel can be composed of 2 sub-pixels or 4 sub-pixels; for an LCD panel with 6 primary colors, each pixel can be composed of 2 sub-pixels, 4 sub-pixels or 6 sub-pixels; thus analogy.

[0057] For the convenience of description, the LCD panel based on the 4-primary color sub-pixel structure is used as an example i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com