A saturable reactor with resistance forming bias voltage

A reactor and resistance technology, applied in the field of saturable reactors, can solve the problems of complex manufacturing process, inability to realize the optimal design of saturable reactors, and large influence of saturable reactor characteristics, achieving simple manufacturing process, easy optimization design, reduction of Effects of Transient Time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

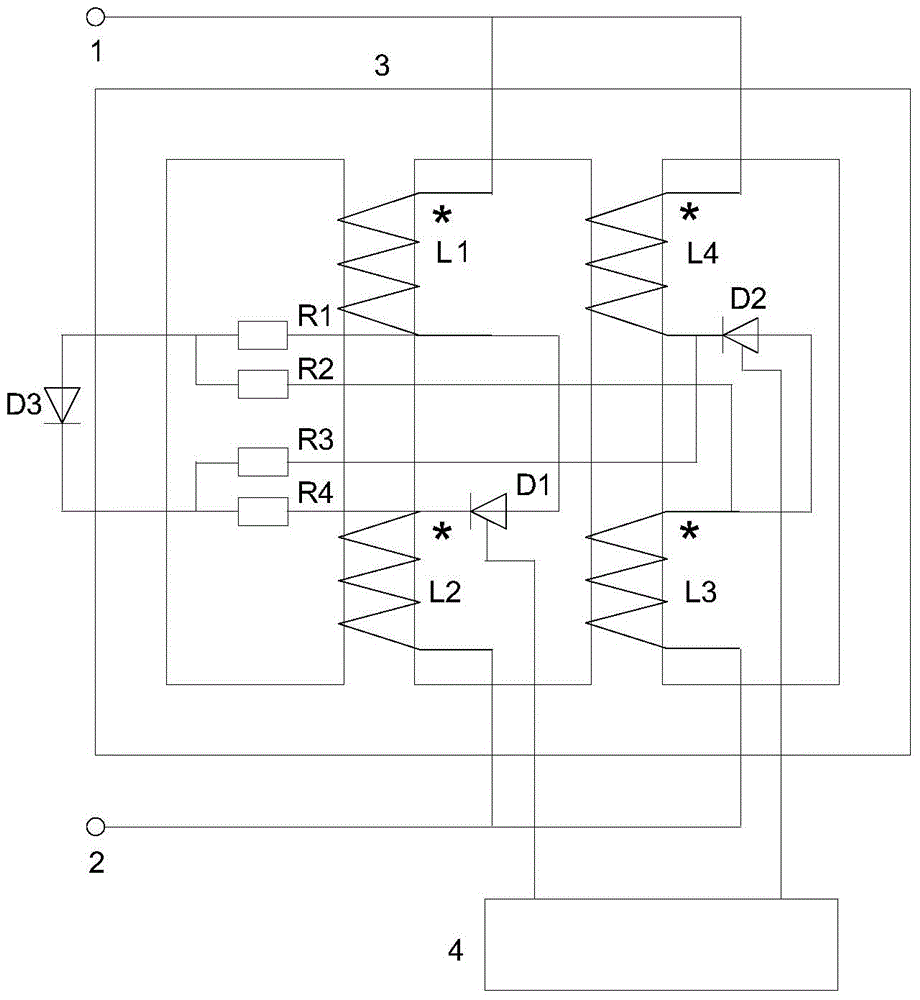

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] The structure and connection method of a saturable reactor in which the resistance forms a bias voltage is as follows: figure 1 shown. Including saturable reactor terminal I1, saturated reactor terminal II2, saturated reactor closed-loop iron core 3, and control circuit 4. The closed-loop iron core 3 of the saturable reactor has at least two iron core columns with the same cross-sectional area and at least two coils; each of the two iron core columns has at least one magnetic flux closed loop that does not pass through the opposite iron core column. One of the iron core columns has a coil L1 and a coil L2, and the other iron core column has a coil L3 and a coil L4; the number of turns of the coil L1, the coil L2, the coil L3, and the coil L4 is equal.

[0028] The closed-loop iron core 3 may be two closed-loop iron cores that have no passages t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com