A Torque Conduction Structure of Superconducting Motor

A conductive structure, superconducting motor technology, applied in the usage of superconductor elements, electromechanical devices, electrical components, etc., can solve the problems of unfavorable large motor assembly, large number of parts, complex rotor structure, etc., to achieve flexible processing solutions, increase Heat conduction path, effect of reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The torque conduction structure 4 for the superconducting motor proposed by the present invention is a support structure composed of materials with a certain bearing force. The overall structure of the support structure is cylindrical. Since the structure has a support structure, the structure of the support is complicated. The loop will produce the extension of the heat conduction path, thereby achieving the effect of reducing heat leakage. Wherein the concrete structure of embodiment one is as follows:

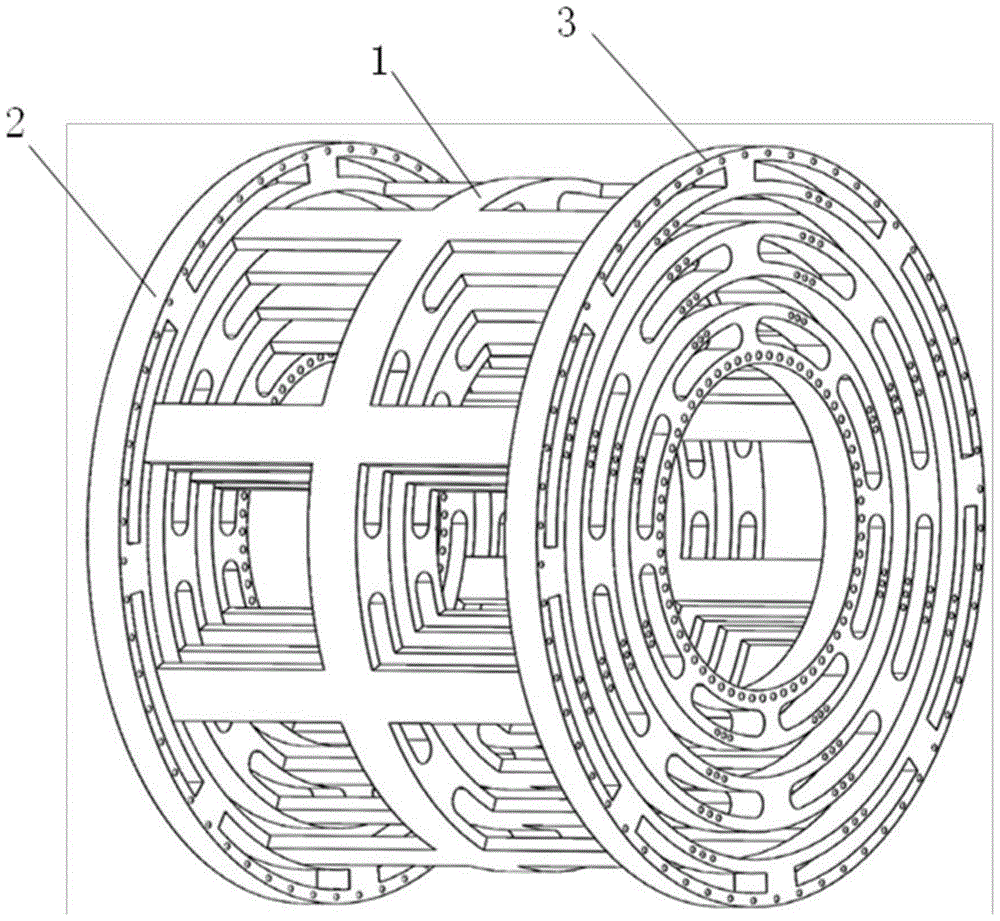

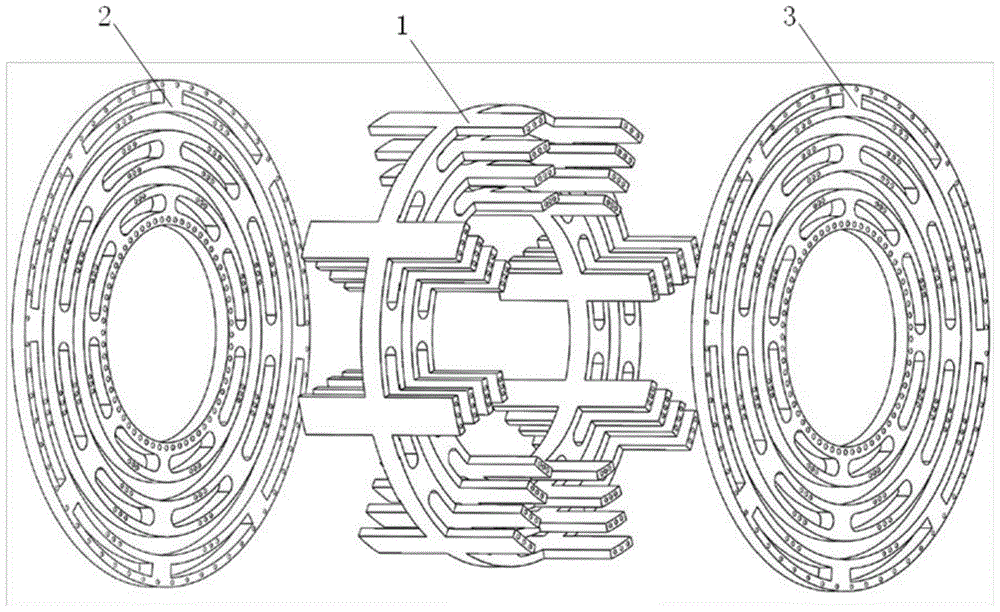

[0033] Such as Figure 1-4 As shown in , it includes a beam structure 1 and annular flange structures 2, 3 connected and fixed at its two ends;

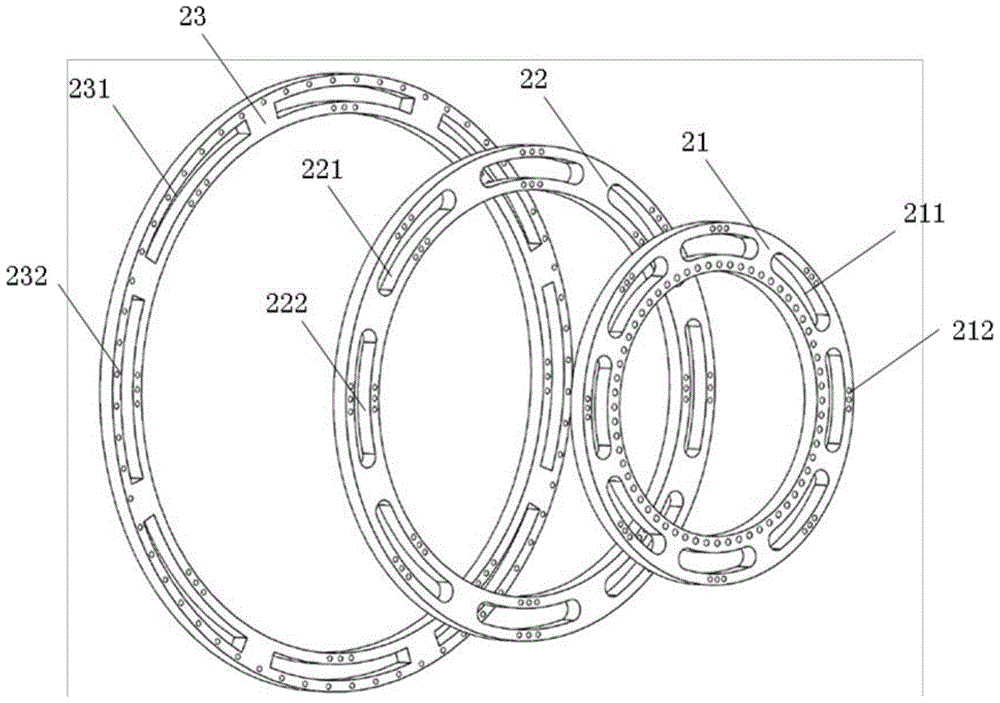

[0034] The annular flange structures 2, 3 include several flange rings 21, 22, 23 sleeved in the radial direction with different diameters, the beam structure 1 includes two sleeved sub-beam structures 11, 12 with different diameters, the sub-beam structure 11 and 12 respectively include central ring pieces 111, 121, and t...

Embodiment 2

[0036] In order to further extend the heat conduction path and reduce heat leakage in this way, a further improved structure is proposed in this embodiment:

[0037] Such as Figure 1-4 As shown, the structure is mainly composed of annular flange structures 2 and 3 perpendicular to the rotor axis, and a beam structure 1 along the axis.

[0038] It includes an outer flange 23 connected to the superconducting low-temperature rotor 5, an inner flange 21 connected to the shaft end 6 of the normal temperature motor, and an intermediate flange 22, wherein the diameters of the flanges 21, 22, and 23 are different, so that the Radial upper system, where such as image 3 As mentioned above, the through holes 211 , 212 , 221 , 222 , 231 , 232 etc. are distributed on the circumference of the flange rings 21 , 22 , 23 .

[0039] A beam structure 1 is arranged between the annular flange structure 2 and the annular flange structure 3, wherein the beam structure 1 includes sub-beam structu...

Embodiment 3

[0042]Of course, the present invention adopts a cylindrical overhead structure to be arranged between the low-temperature rotor 5 and the shaft end 6 of the normal-temperature motor. Of course, the way of extending the heat conduction path is not limited to the above-mentioned way. In the third embodiment, the sub-beam structure The through-holes in the central rings 111, 121 expand in the radial direction, thereby dividing the central ring into two parts in the radial direction, thereby expanding the number of plates 112, 113. Corresponding through holes are provided on the flanges of the flange structures 2 and 3 to fix the expanded plates.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap