Mechanism for detecting camera of fully-automatic backlight assembly machine

A detection mechanism, camera technology, applied in television, electrical components, image communication and other directions, can solve the problems of camera detection mechanism accuracy and mechanism adjustment performance is not small and practical, and achieves a small footprint, efficient operation, and simple mechanism adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

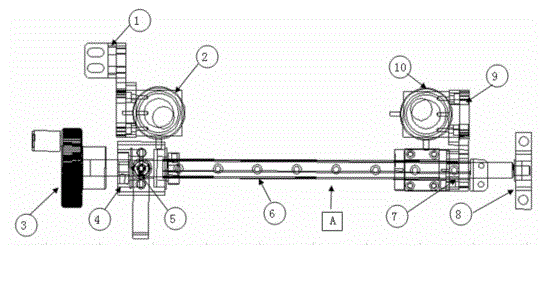

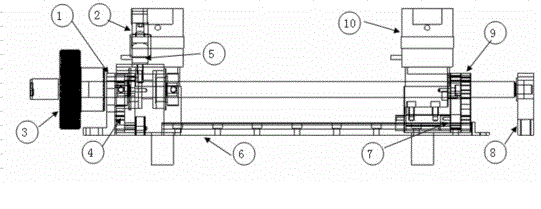

[0009] The automatic backlight assembly machine is to combine the glass and the backlight film, and the camera detection is an important part of the machine. Provide guarantee for the speed and quality of the whole machine. Directly affect work efficiency and product quality. The camera detection mechanism includes: fixed part 1 to fix the camera 2, move the camera side, hand wheel 3 to connect the workpiece 4, install 2 bearings in the cavity of the workpiece 4, install the handle 5, install the linear guide rail 6 under the workpiece, and the linear guide rail The top of the 6 is connected with the moving block 7, the camera mounting plate 9 is installed on the side, and the camera alignment is installed, and the fixed side 8 is installed at the tail end, and the bearing is installed inside. Manually rotate the hand wheel to move the camera position.

[0010] Position the camera to detect the fixed MAX point, fine-tune the camera to ensure the focal length, and move the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com