Method for Assembling the Push Rod

A push rod and housing technology, applied in the field of push rod assembly, can solve problems such as easy assembly of disc bridges, and achieve the effect of simple tolerance compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

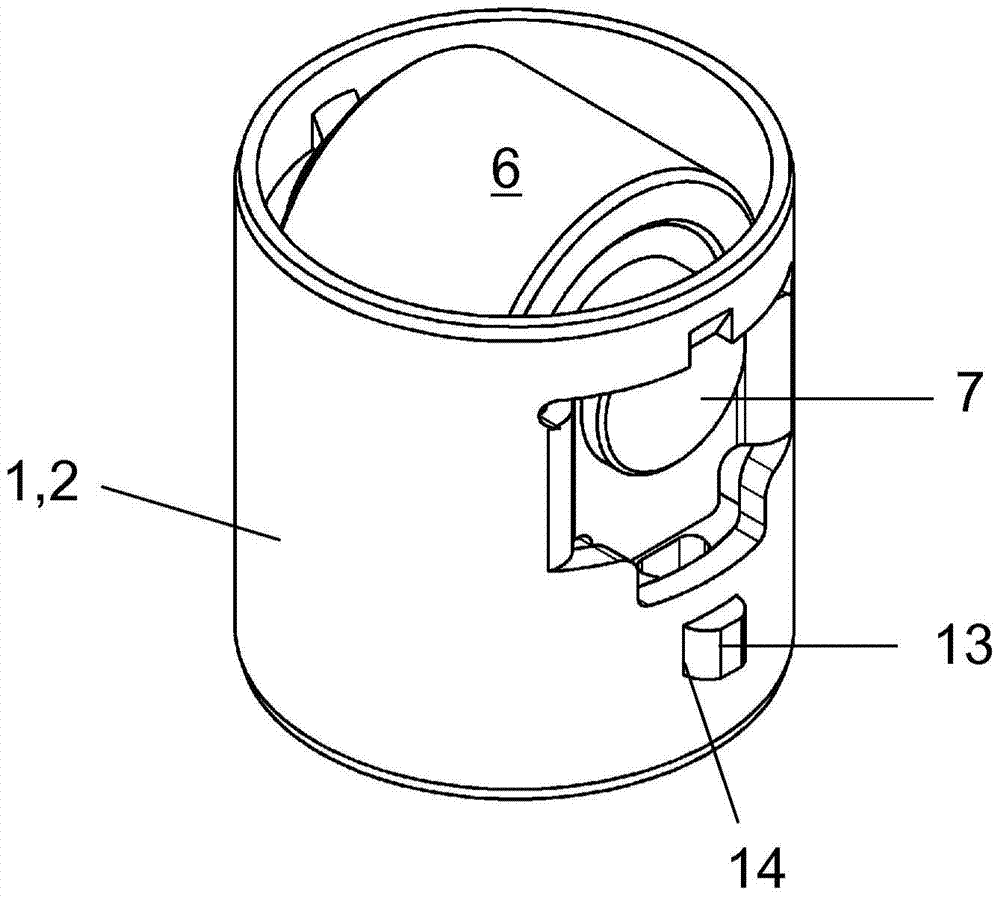

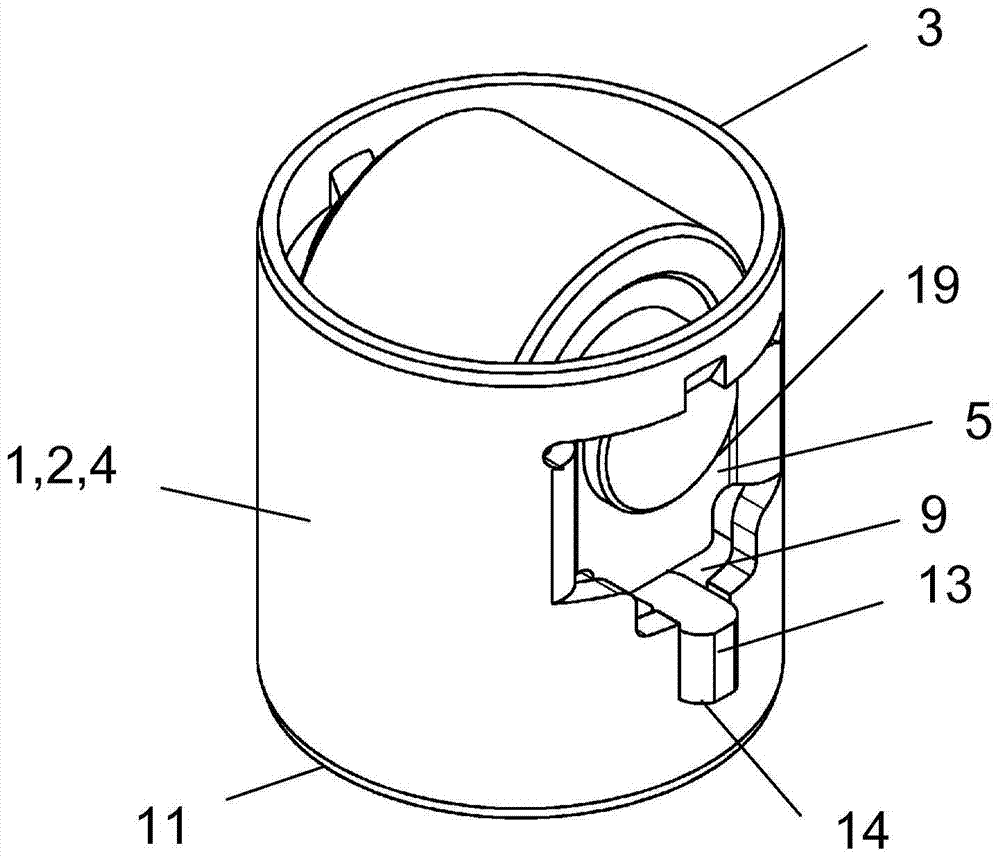

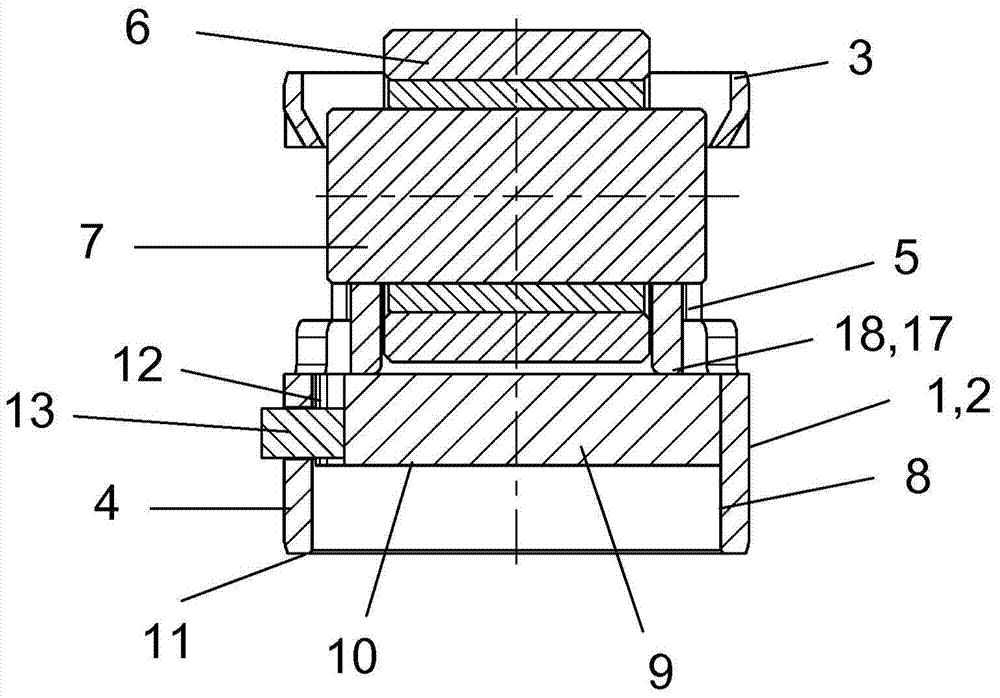

[0023] Depend on Figures 1 to 3 The pushrod 1 for the high-pressure fuel pump is known from . The push rod has a tube-like housing 2 made of steel sheet. In the drive-side annular end edge 3 of the housing 2 , two flats 5 set back from the outer peripheral side 4 of the housing 2 are diametrically opposite each other. A pin 7 is accommodated in the bore 19 of the flat part 5 , over which runs a needle-supported roller 6 for running the cam or eccentric.

[0024] The inner peripheral side 8 of the housing 2 is traversed axially below the rollers 6 by a bridge 9 which is present as a thick-walled longitudinal beam. Thus, between each longitudinal wall 20 of the bridge 9 and the inner peripheral side 8 of the housing 2 there remains a cylindrical segment-shaped surface for a relatively unhindered penetration of the lubricant.

[0025] as best from image 3 As inferred from , the bridge 9 rests against the abutment 17 in the direction of the drive-side annular end edge 3 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com