A balancing device and a mustard harvesting device comprising the balancing device

A technology of a balancing device and a harvesting device, which is applied in the directions of harvesters, cutters, agricultural machinery and implements, can solve the problems of shortage, low work efficiency and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

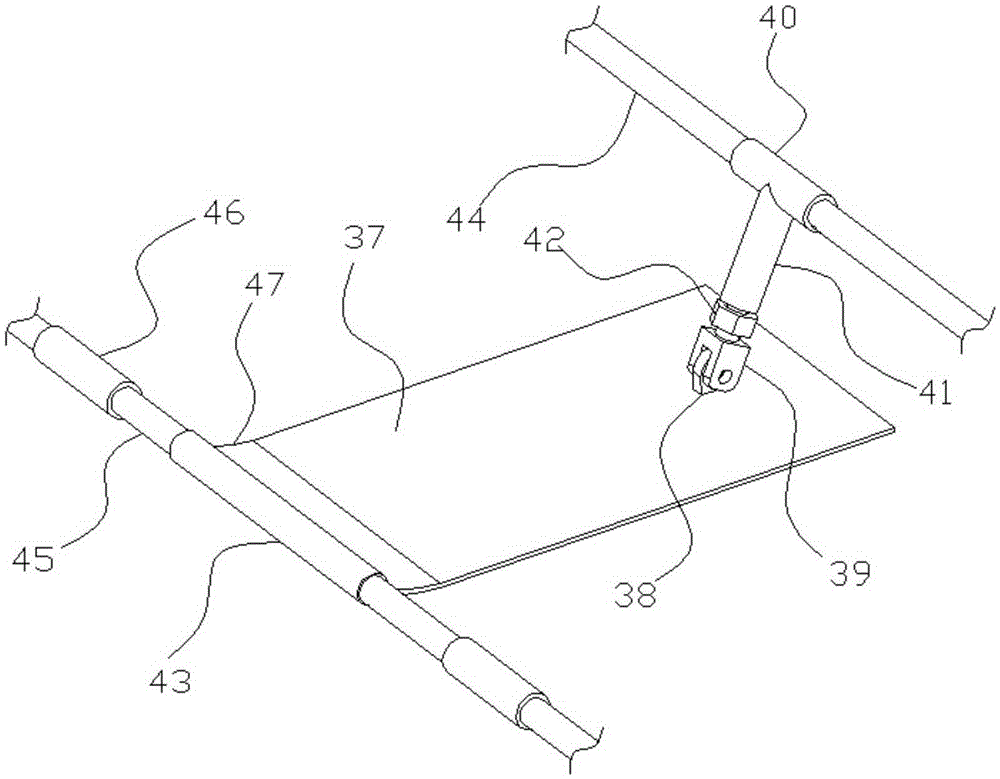

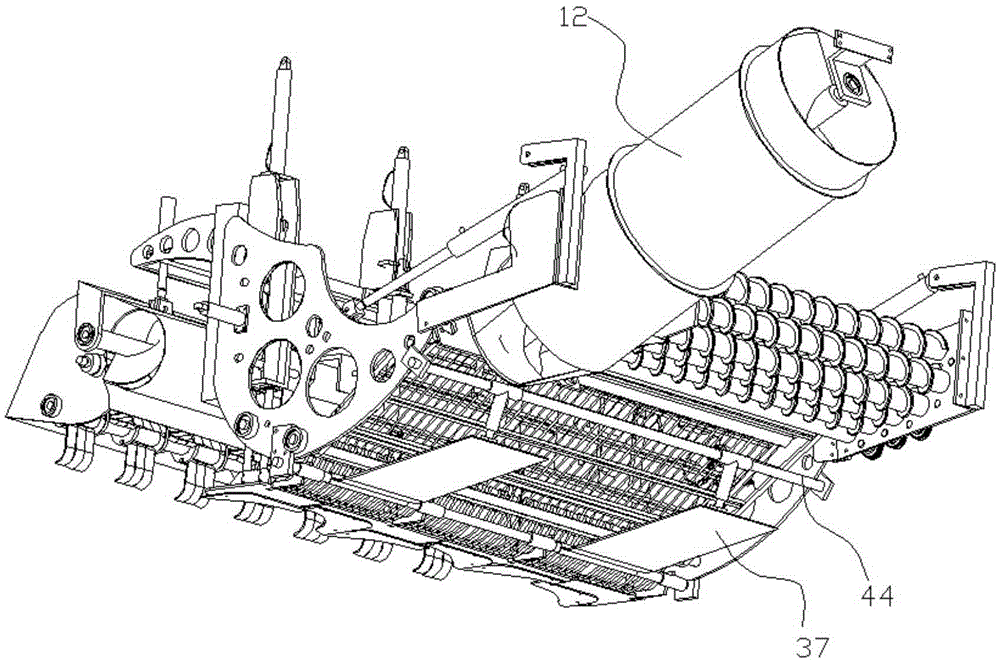

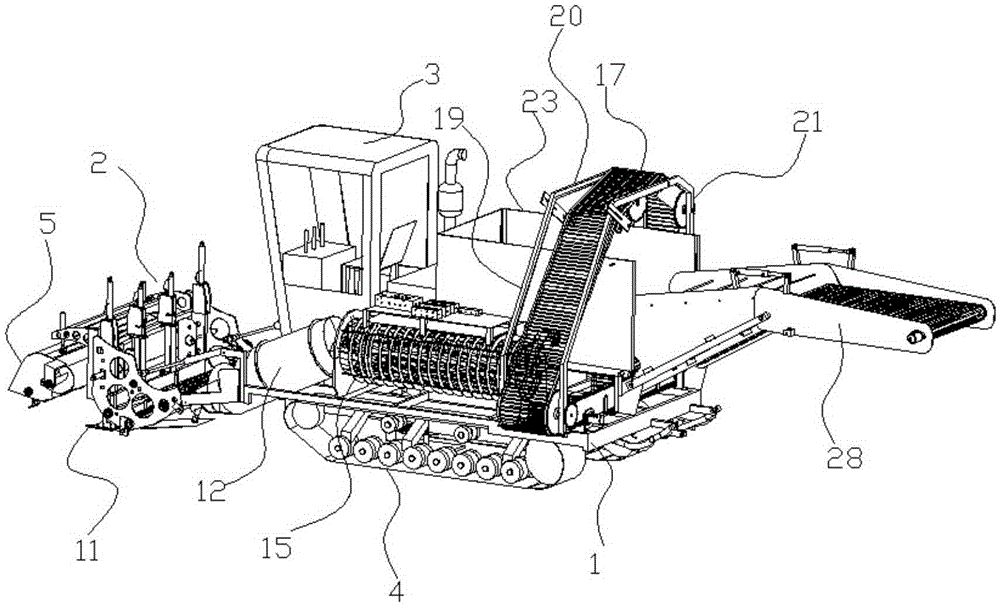

[0027] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 In the shown embodiment, a kind of balance device comprises at least one balance plate 37, and described balance plate is provided with connector 38, T-shaped fixed rod, and described T-shaped fixed rod comprises lower connecting block 39, fixed Main rod, T-shaped sliding sleeve, the lower connecting block is hinged with the connecting head, and the T-shaped sliding sleeve includes an upper horizontal connecting sleeve 40 and an oblique vertical sliding sleeve 41, and the oblique vertical sliding sleeve and the fixed main rod Sliding connection, the fixed main rod is provided with an adjusting nut 42 threadedly connected with the fixed main rod, the described adjusting nut is located below the inclined sliding sleeve, and the described balance plate is provided with a lower horizontal connecting sleeve 43, An upper adjusting cross bar 44 that is rotatably connected wit...

Embodiment 2

[0035] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 8 , Figure 9 , Figure 10 As shown, the fuselage is provided with a material distribution device, and the material distribution device includes a guide arc plate 30, a material distribution arc plate 31, an arc-shaped material distribution spring net 32, and a material distribution adjustment cylinder 33. The arc-shaped material distribution elastic net is connected on the material distribution arc plate, and the space between the material distribution arc plate and the arc-shaped material distribution elastic net is the screening part 34, and the described material distribution arc plate is attached to the guide arc On the board, the radian of the bottom surface of the material distribution arc plate matches the top surface curvature of the guide arc plate, and the piston rod of the material distribution adjustment cylinder is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com