Underground filter device for well logging during drilling

A filtering device and logging-while-drilling technology, applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve problems such as the inability of drilling fluid to flow normally, reduce work efficiency, and increase drilling costs, and achieve structural Simple, reliable, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further analyzed below in conjunction with specific accompanying drawings.

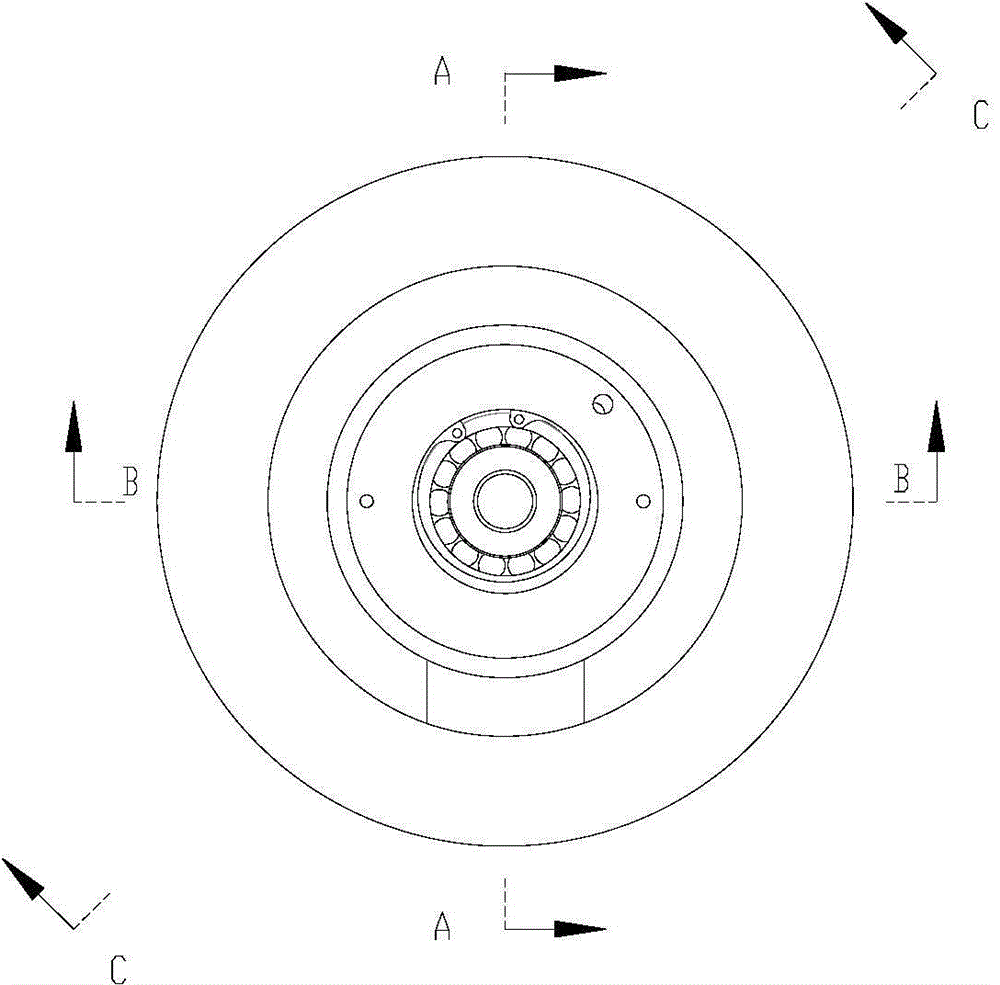

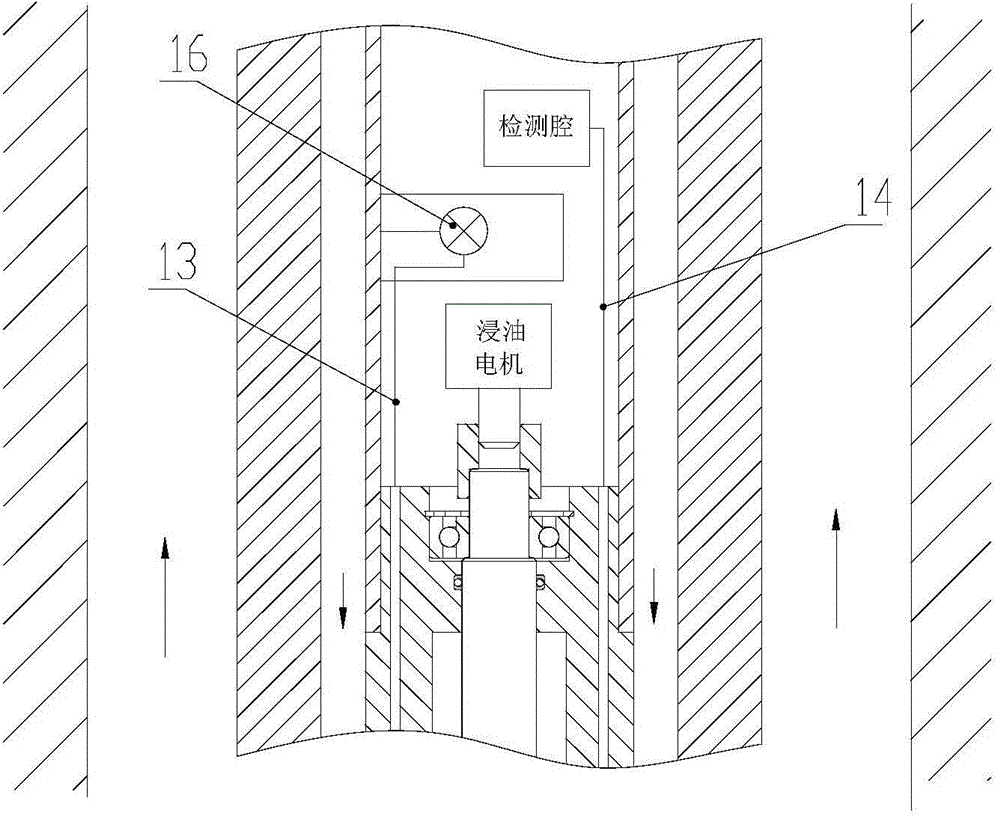

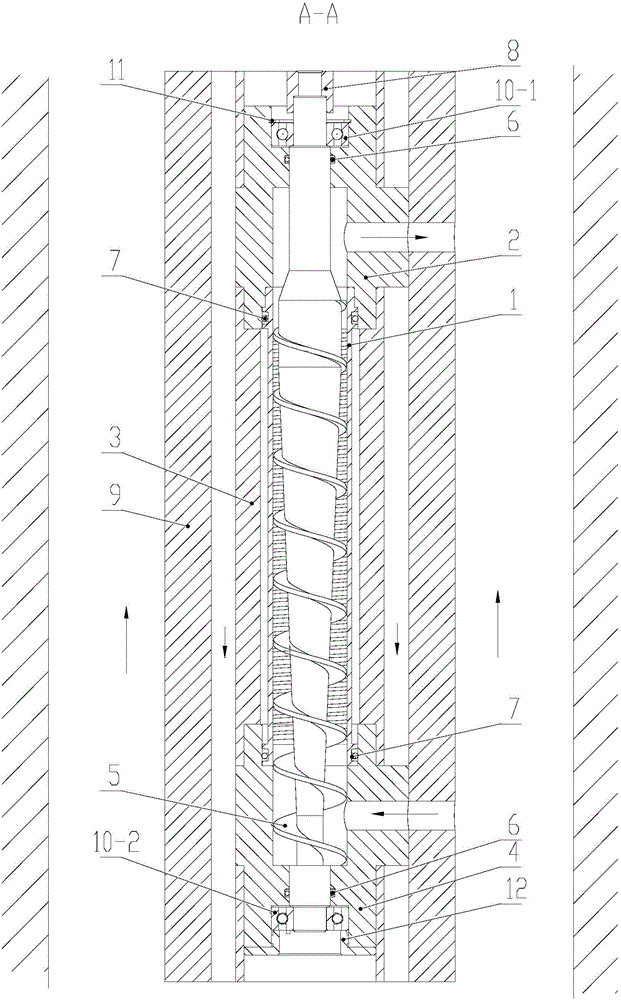

[0022] Such as figure 1 , 3 As shown, the downhole filter device of the present invention includes a screw shaft 5, a filter screen 1, and a sleeve 3 in order from the center to the periphery; the top end of the screw shaft 5 is fixed to the upper joint 2 through the upper bearing 10-1, and the end is fixed to the upper joint 2 through the lower bearing 10-2. Fixed on the lower joint 4; the end of the lower joint 4 is connected to the end cover 12 through the flange, and the end of the lower joint 4 and the end cover 12 are connected by a gasket, and the upper bearing 10-1 and the lower bearing 10-2 are adjusted by the gasket clearance and preload, so that the upper bearing 10-1 stops on the circlip 11 embedded in the groove of the upper joint 2; the top end of the screw shaft 5 is connected to the oil-immersed motor through the coupling 8; the upper joint 2, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com