A method for obtaining additional load loss coefficient of machine tool cutting system

A technology of cutting processing and loss coefficient, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as the difficulty of additional load coefficient of machine tools, modeling of machine tool idle power, and complex calculation of machine tool cutting power. Achieve the effects of improving the energy efficiency of machine tools, simplifying the acquisition of additional load loss coefficients, and improving practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

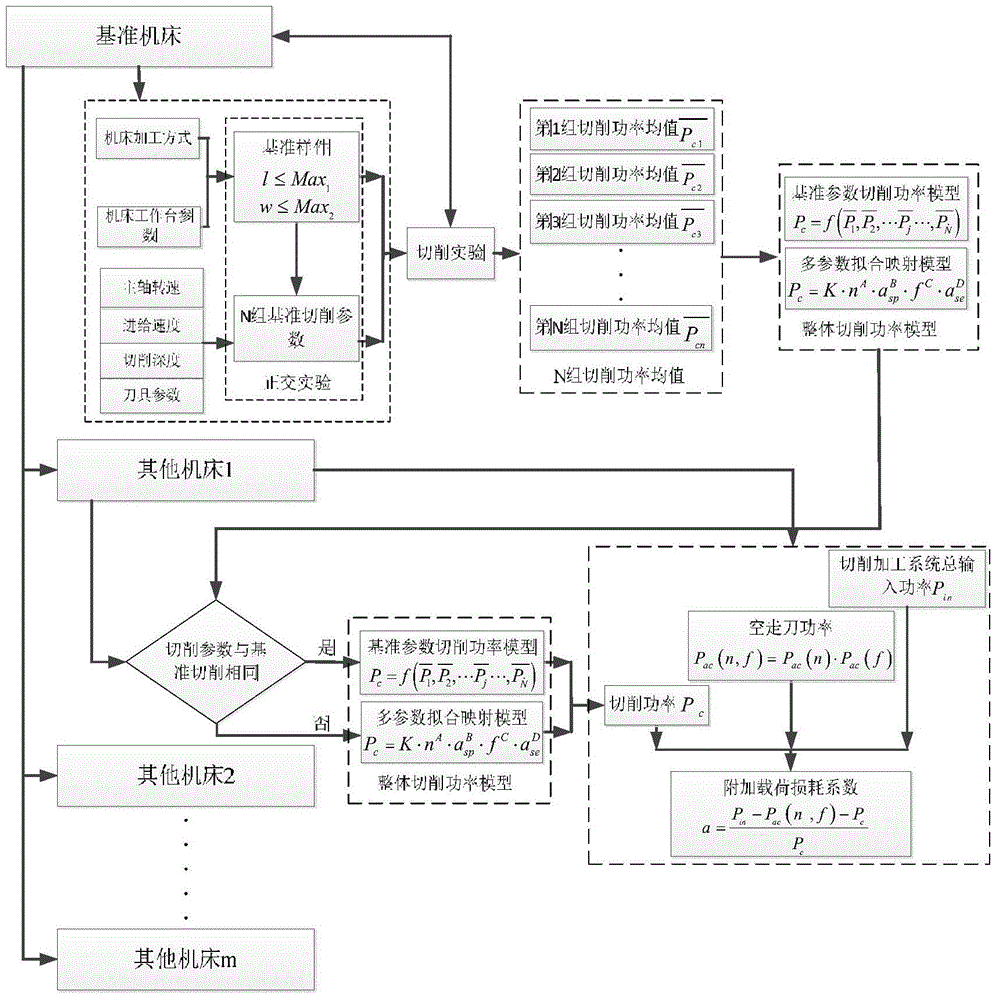

[0033] see figure 1 , the present invention proposes a method for obtaining the additional load loss coefficient of the machine tool cutting system, the method is to obtain the overall cutting power model of the cutting system by designing the reference sample and the reference cutting parameters, and based on the model and other machine tool idling tool Power and detect the total input power of other machine tool cutting processing systems, and obtain the additional load loss coefficients of other machine tool cutting processing systems according to the additional load coefficient acquisition model. The specific implementation is as follows:

[0034] 1. Design of reference sample and reference parameters: The reference sample is designed according to the size of the machine table and the stroke range. Use l and w to represent the length and width of the reference sample, L m and W mrepresent the length and width of the machine table, respectively. Considering the installat...

Embodiment

[0079] On the milling machining center PL700 machine tool and the 5-axis vertical machining center HASS VF-5 / 50TR, the method of the present invention is used to calculate the additional load loss coefficient of the HASS VF-5 / 50TR through the milling power mapping model obtained on the PL700, and the process is as follows :

[0080] 1. Design of reference samples and reference parameters:

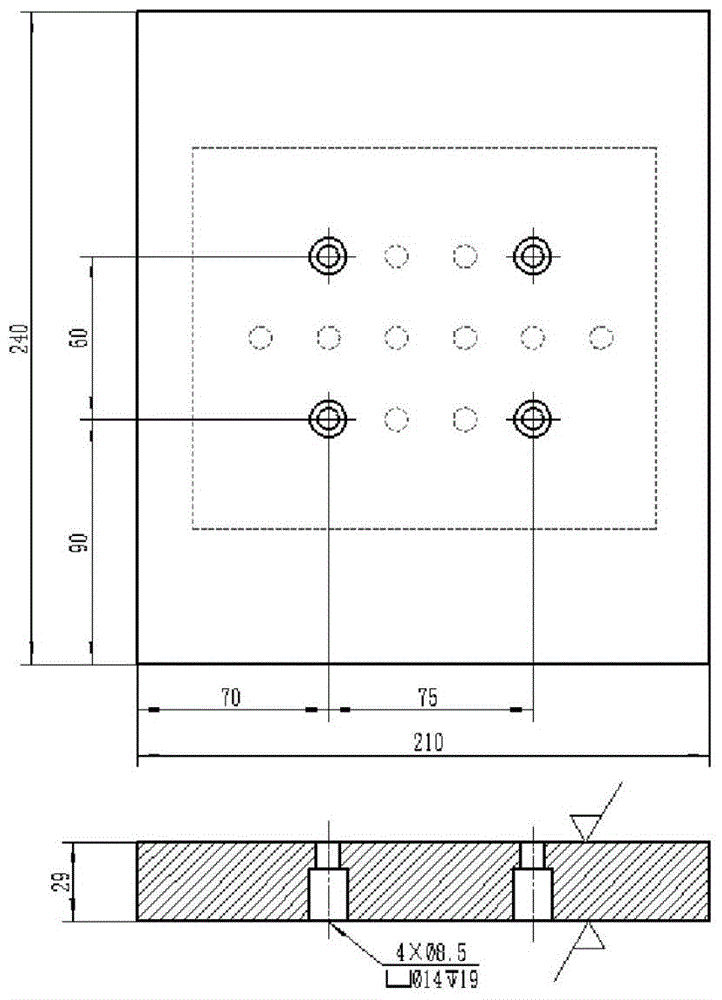

[0081] According to the conditions that the reference sample and reference parameters need to meet and the PL700 machine tool parameters (such as Table 3 and Table 4), select a 45 steel plate with a geometric size of 240x210x29 (mm) as the reference sample, such as figure 2 shown. The cutting tool is the RPEW1003MO HP7025R5 thin blade of Rui Nike Precision Tool, the maximum diameter of the cutting edge is 25mm, and the minimum diameter is 15mm. Kistler9257B multi-functional force measuring instrument, 5670A data acquisition system and 5070 channel charge amplifier are used to measure cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com