Heavy three-way pipe hoisting device

A hoisting device and tee-pipe technology, which is used in transportation and packaging, load hoisting elements, etc., can solve the problems of easy grinding of the edge of the tee pipe, abrasion of the inner wall of the tee pipe, and difficulty in installing and sealing the tee pipe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

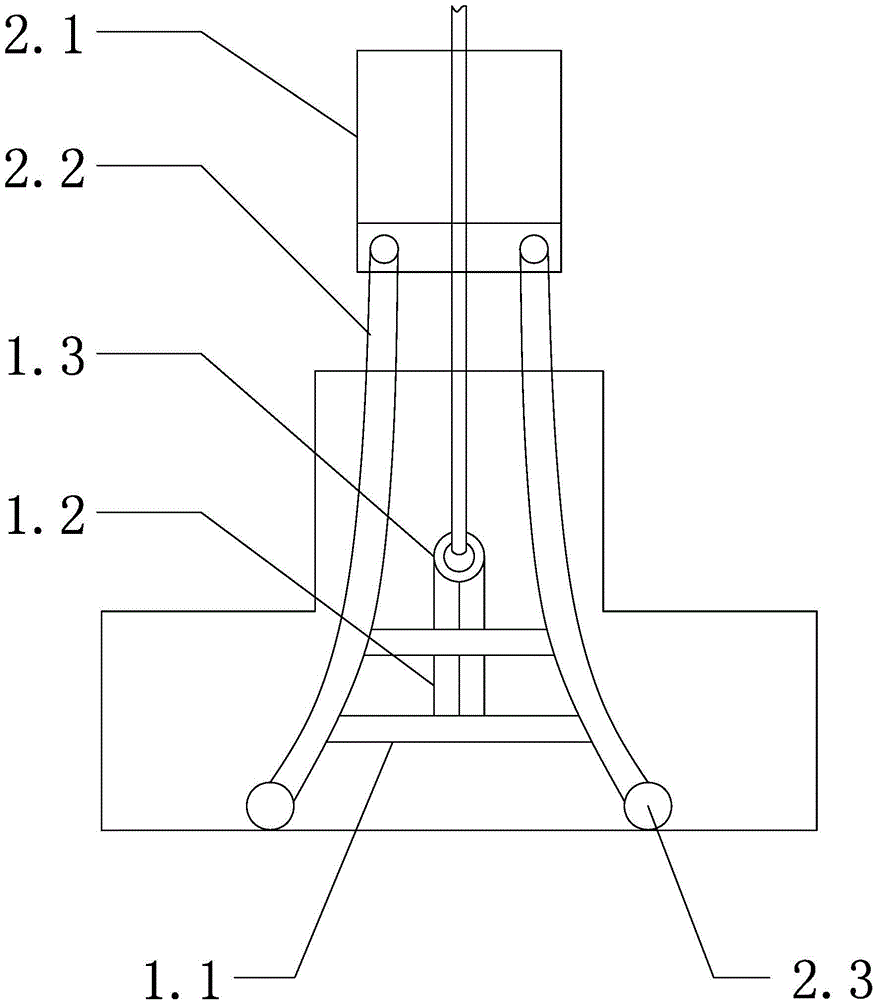

[0015] Such as figure 1 The lifting mechanism shown includes: a lifting disc 1.1 and a lifting straight rod 1.2 vertically fixed to the lifting disc 1.1; the lifting disc 1.1 is a disc; the upper end of the lifting straight rod 1.2 has a hanging ring 1.3 for fixing a wire rope;

[0016] The embedded hoisting mechanism includes: a fixed seat 2.1, an arc-shaped extension claw 2.2 fixed to the outer wall of the fixed seat 2.1 through a hinge shaft; the number of arc-shaped extension claws 2.2 is an even number, and the fixed seat 2.1 is symmetrically distributed to the circumference of the fixed seat 2.1. To the outer wall; the arc-shaped extension claw 2.2 is a concave arc;

[0017] The lifting plate 1.1 is located on the fixing seat 2.1, and is located between two opposite arc-shaped extension claws 2.2; the fixing seat 2.1 is provided with a through hole for the wire rope to pass through;

[0018] In the present invention adopting the above-mentioned technical solution, first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com