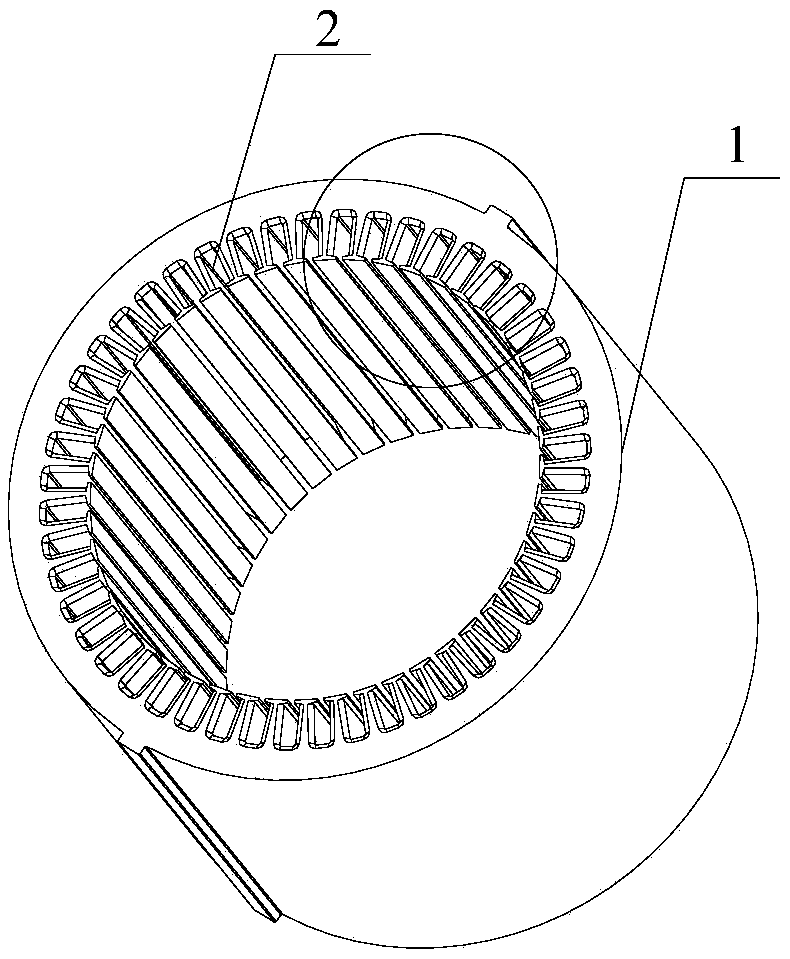

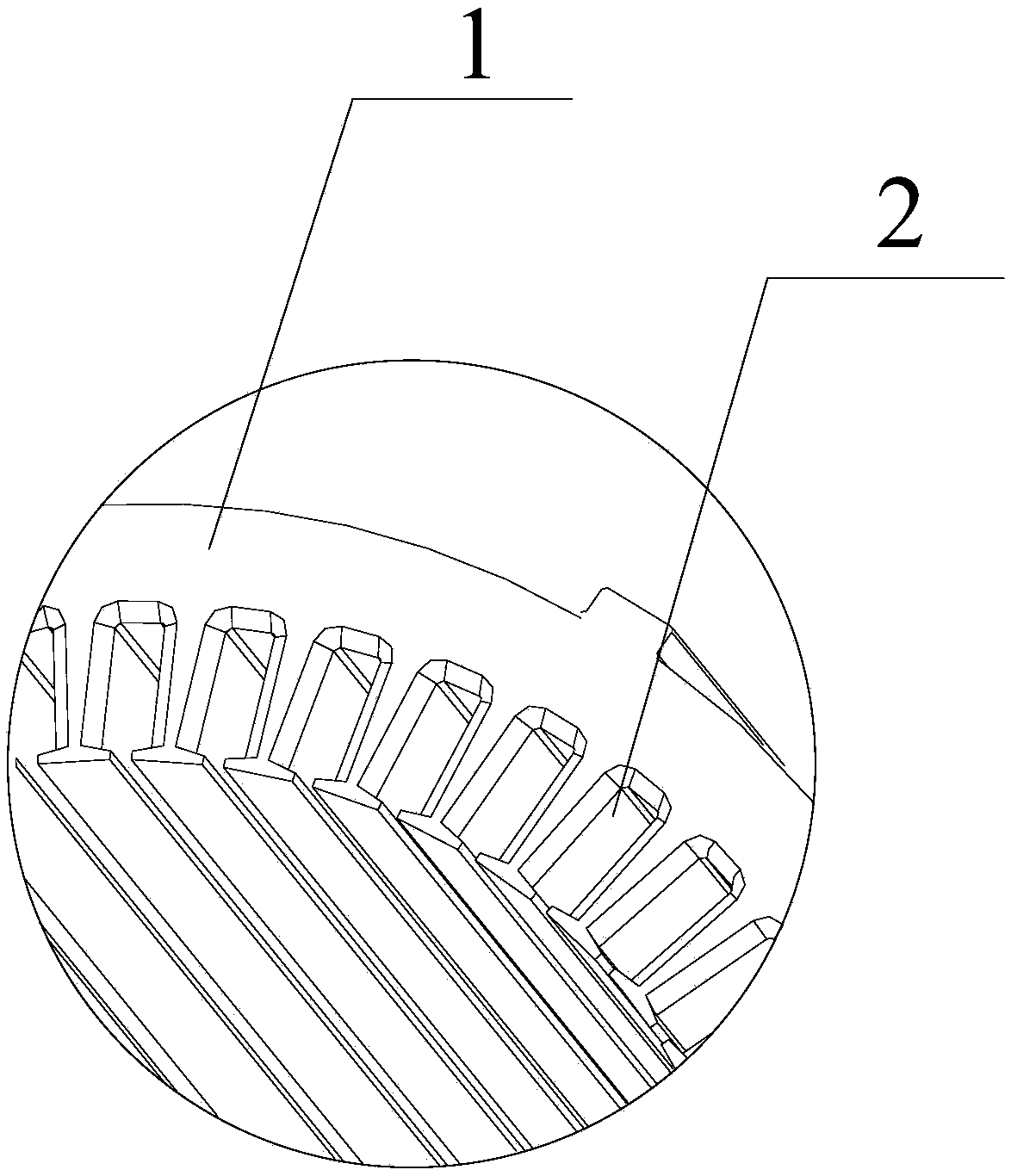

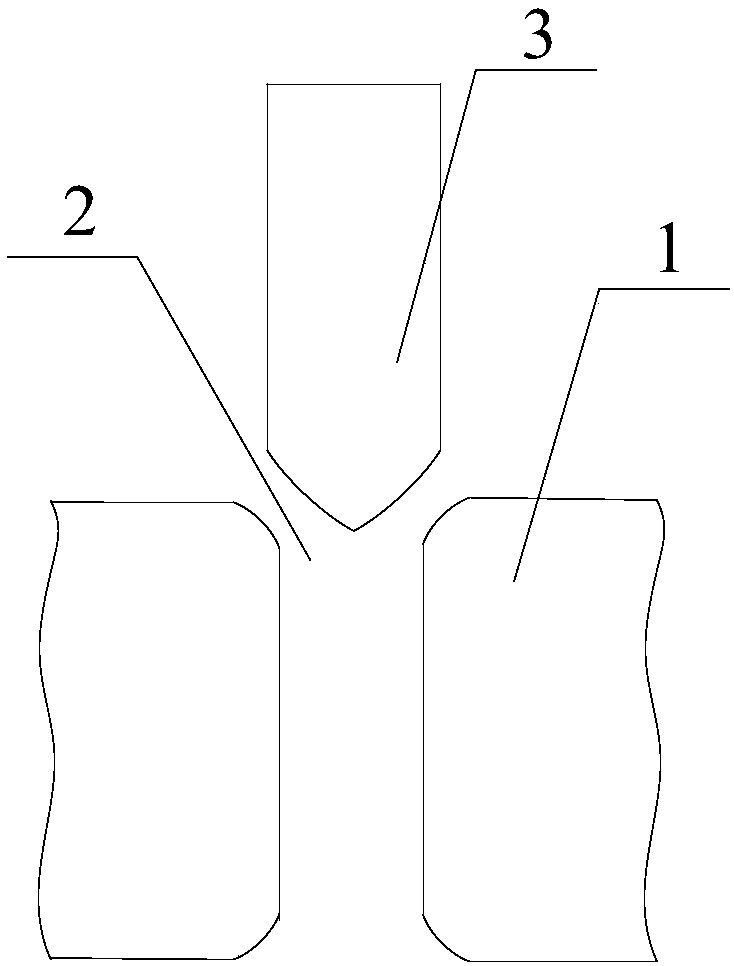

Motor stator groove opening structure

A motor stator and stator slot technology, which is applied to the shape/pattern/structure of magnetic circuit, the shape/pattern/structure of winding insulation, the shape/pattern/structure of winding conductor, etc., can solve the problem of increasing the height of winding wire ends, insulating paper Damage, increased cost and other problems, to achieve the effect of reducing the height of the end and facilitating the insertion of copper wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The concrete implementation method of the present invention is as follows:

[0019] The existing square copper wire motors are developed from card-generating motors, so the existing square copper wire motors are mostly motors with distributed winding technology, which essentially adopts segmented wave winding technology. Compared with the traditional Distributed winding motors with random embedded coils can significantly increase the occupation rate of copper wires in the slot, and can significantly reduce the height of the non-welded end windings. The process engineering generally includes: segmented copper wire forming, stator Iron core insertion, segmented copper wire insertion, copper wire twisting on the other side, copper wire welding on the other side, and insulation treatment at the welding point. However, due to the large twisting torque, the winding copper wire and the stator notch will have a large The extrusion force of the winding will cause the wear and te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com