New Rotary Seal Valve

A rotary sealing valve, a new type of technology, applied in the direction of rotary conveyors, transportation and packaging, conveyors, etc., can solve the problems of inability to ensure the operation rate of equipment, small particle extrusion wear, and high failure probability in use, so as to improve the service life , Solve extrusion wear and ensure the effect of equipment operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

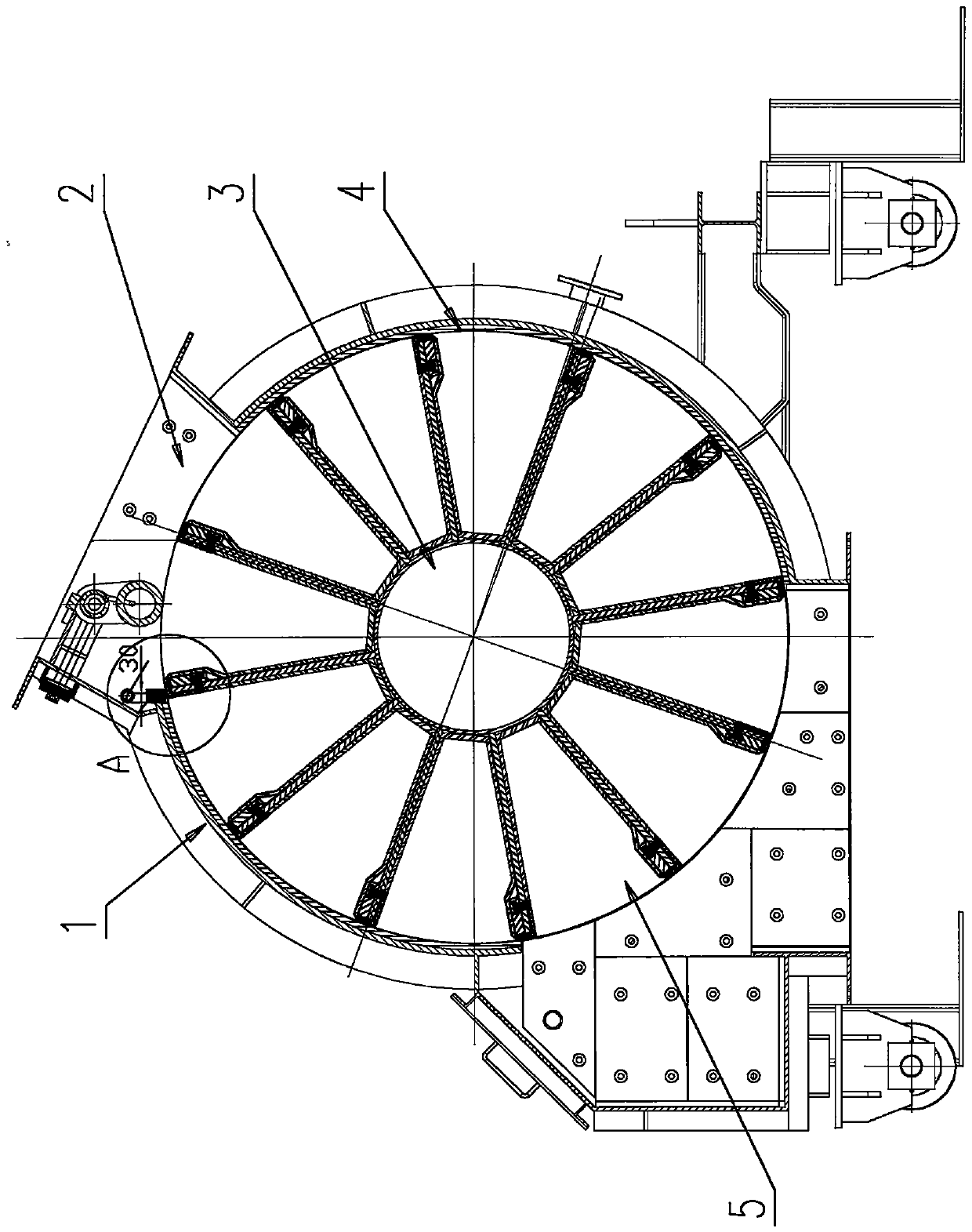

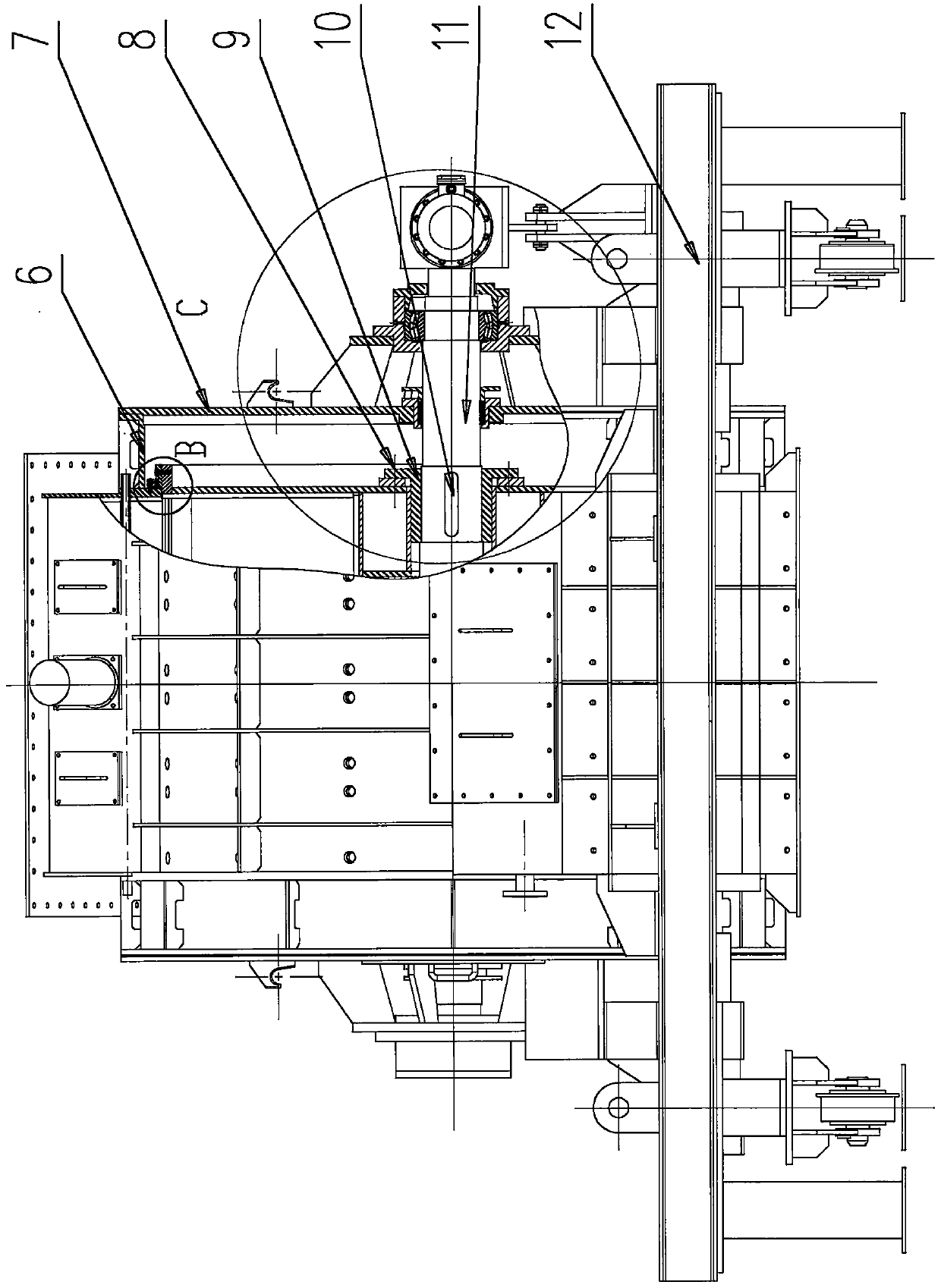

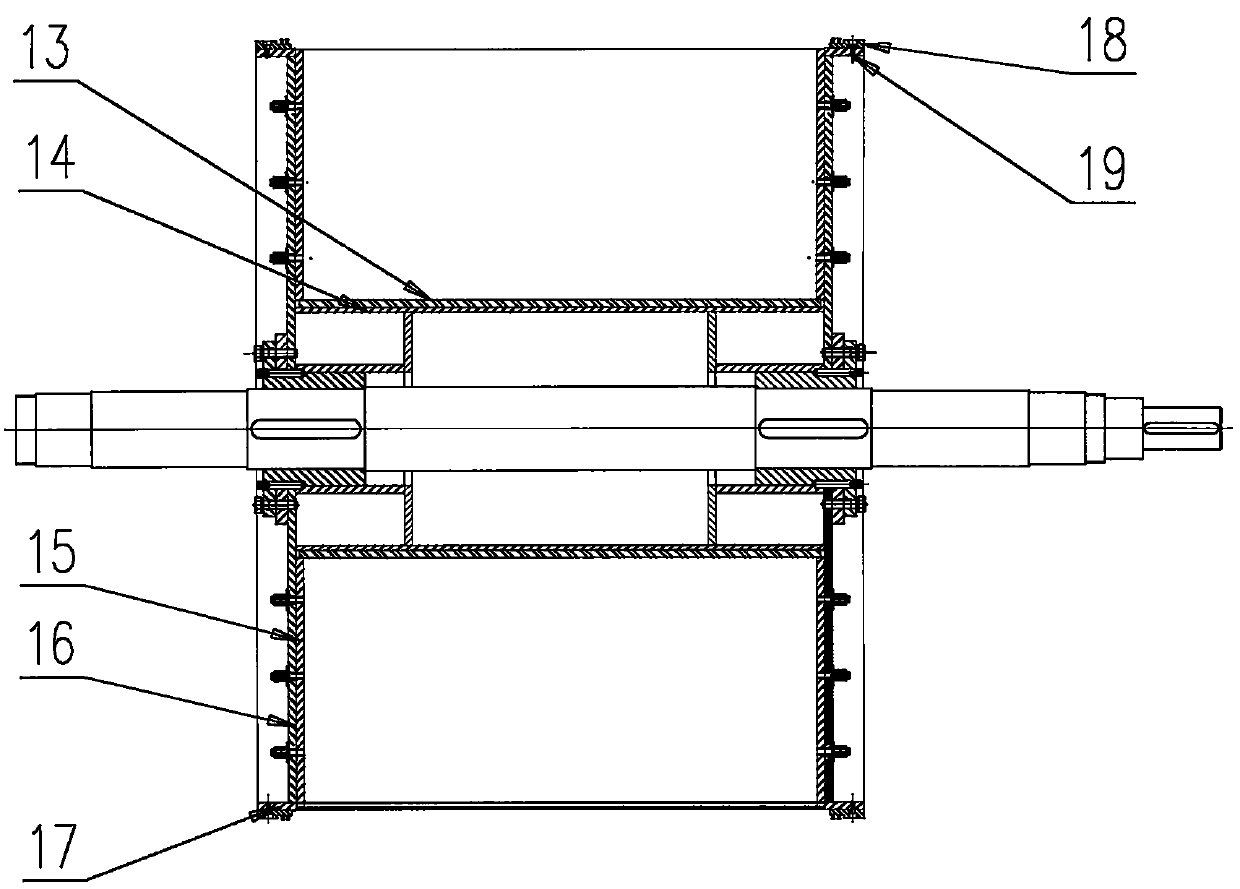

[0021] Such as figure 1 , figure 2 As shown in the figure, the new rotary sealing valve includes a valve body 1 and a star-shaped rotor assembly 3 located in the valve body 1, which are installed together through the transmission shaft 11 and the end covers 7 at both ends, and the valve body 1 is provided with a valve body liner 4 , There is a material inlet 2 on the top and a material outlet 5 on the bottom, the valve body 1 is installed on the trolley 12 through the end covers 7 at both ends, and the material inlet 2 is located above the star rotor assembly 3 , the discharge port 5 is located below the star rotor assembly 3, and the two ends of the trolley 12 are provided with trolley mounting plates 51; as Figure 8 , Figure 9 As shown, the two ends of the valve body 1 are provided with end caps 7, and the end cap bottom plate 49 on the end cap 7 is fixed on the trolley mounting plate 51 by bolts five 52, and is fixed on the platform by being arranged on the end cap bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com