A composite biological deodorization process and device using non-bubble aeration pretreatment

A non-foam aeration, biological deodorization technology, applied in air quality improvement, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of short odor residence time, incomplete removal of odor substances, biological fillers or activated sludge Insufficient contact, etc., to achieve sufficient deodorization effect, improve deodorization effect, and increase the effect of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

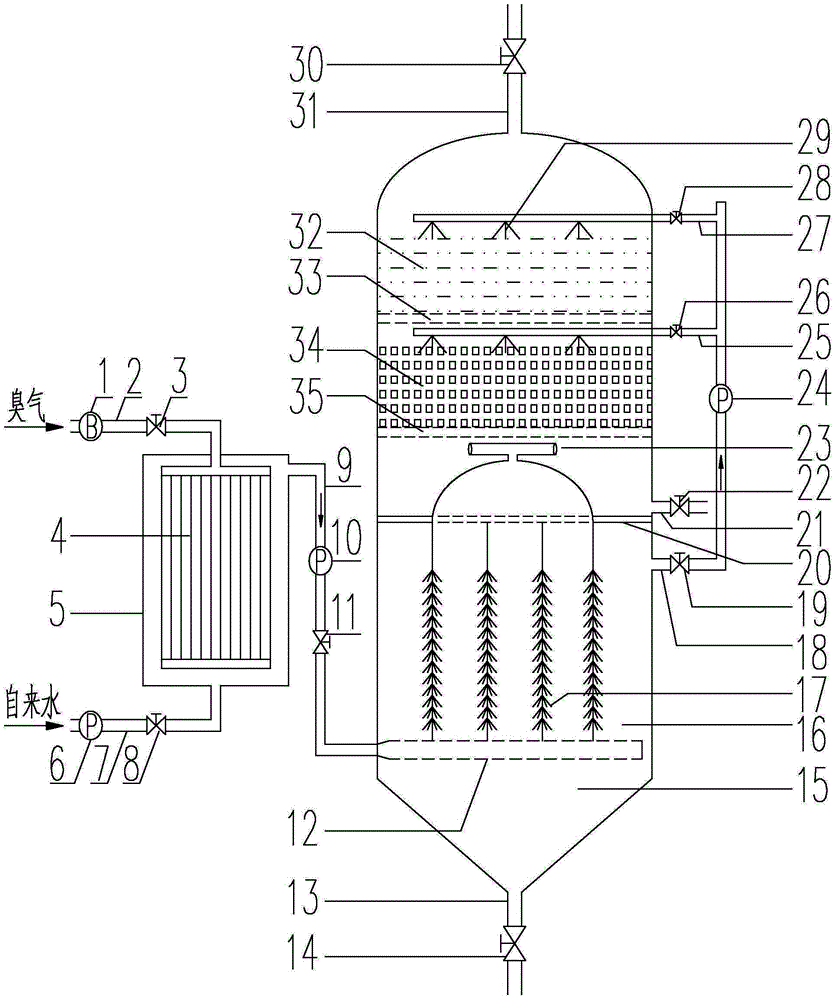

[0044] An embodiment of the compound biological deodorization device using bubble-free aeration pretreatment according to the present invention, refer to figure 1 . Taking the odor between the grilles of a sewage plant as the treatment object, the flow rate of the odor is 6m 3 / h, the main pollutant concentration in the odor is: NH 3 6mg / L,H 2 S5mg / L. The odor is blown into the hollow fiber membrane of the membrane module 4 through the air compressor 1, and the aeration pressure of the membrane module is controlled at 1MPa. Medium pollutants (NH3, H2S, VOC, etc.) dissolve in water to form NH 4 + plasma compound.

[0045] The gas-water flow ratio is set to 2000, and by adjusting the water inlet pump 6 and the water delivery pump 10, the flow rate of tap water and the mixed solution is controlled to be 3L / h, and the residence time of the mixed solution containing pollutants in the activated sludge liquid phase reaction zone 16 is 4h , Under the action of the aerobic-anoxi...

Embodiment 2

[0049] In the described embodiment 1, the odor and the water flow ratio are adjusted to 1500, and the residence time of the mixed solution in the activated sludge liquid phase reaction zone 16 is 3h, and other conditions are as embodiment 1. At this moment, the pollutant removal rate is the same as Compared with Example 1, it has slightly decreased, and the odor after treatment still meets the first-class standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com