Water-lubricated thrust pad lateral elastic baffle limit structure

A technology of elastic baffle and limit structure, which is applied to sliding contact bearings, rotating bearings, shafts and bearings, etc., can solve the problem of increasing cost and complexity, locking that does not reach the expected loosening, and multi-process cost control Cost and other issues, to achieve the effect of increasing the preload function, reducing the effectiveness, and reducing the complexity of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

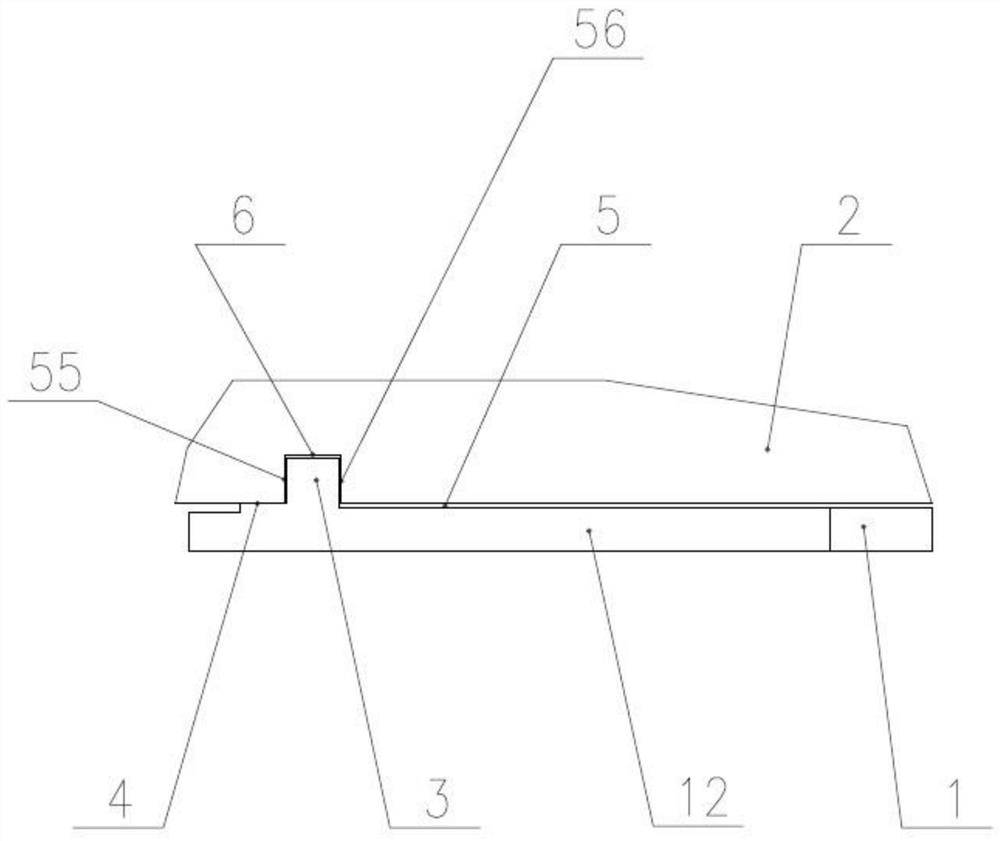

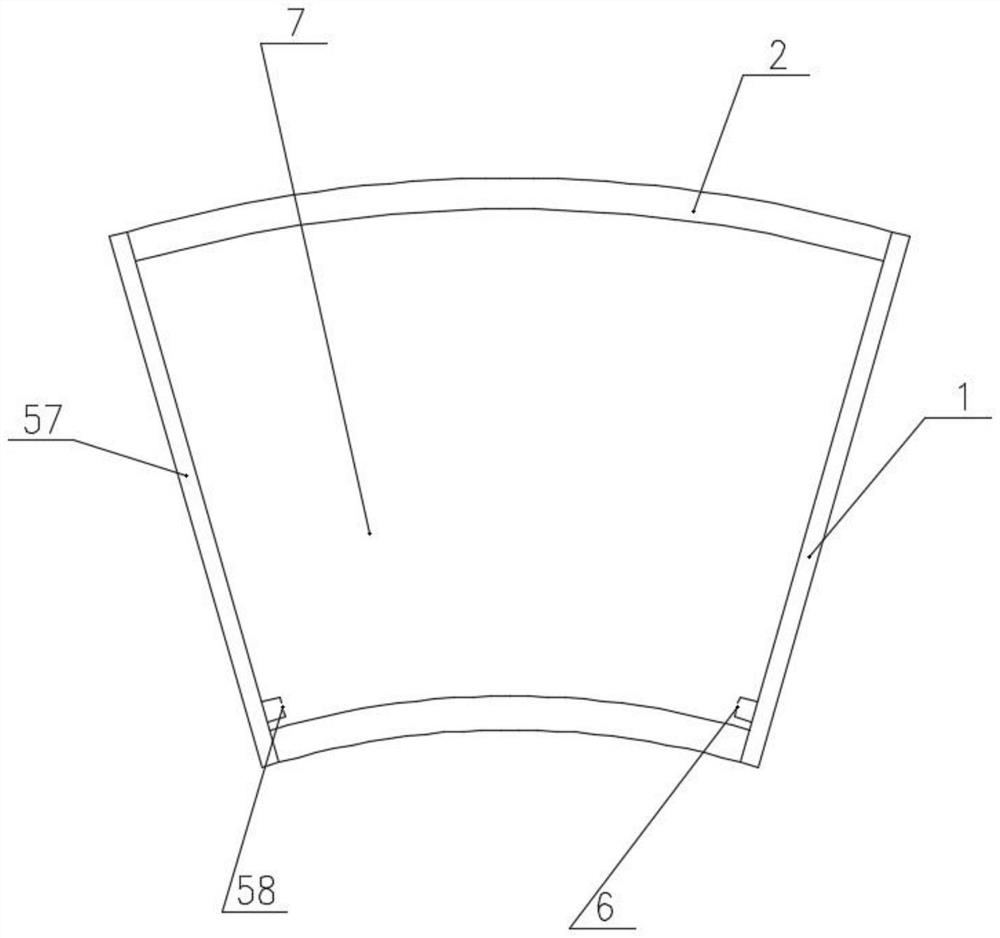

[0025] figure 1 It is a water-lubricated thrust tile lateral elastic baffle limit structure suitable for third-generation nuclear power plants. It is composed of side baffles, tile bases, and tile surfaces. The invention adds a self-locking structure, the side baffle is inserted into the side groove of the thrust tile to lift the lock arm, and the side baffle is inserted into the thrust tile to the position and then the lock arm is lowered, so that the limit head of the lock arm snaps into the thrust tile, And the preload step is set to keep the relative position of the side baffle and the tile base fixed, avoiding the cumbersome structure of the traditional water-lubricated bearing pad using screws to close the side baffle, reducing parts and improving reliability.

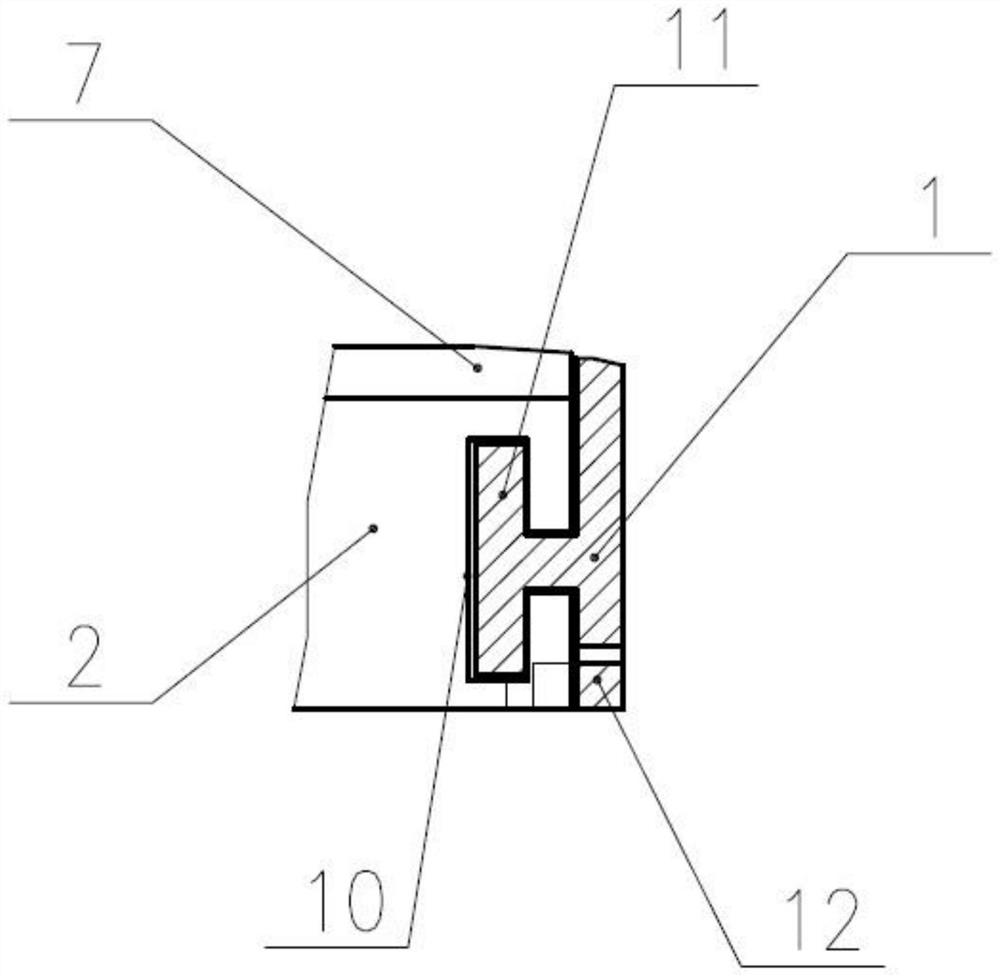

[0026] Such as figure 1 As shown, the water-lubricated thrust pad side elastic baffle limit structure, the first side baffle 1 is provided with a lock arm 12, the lock arm 12 is a cantilever beam structure, and ...

Embodiment 2

[0033] Such as Figure 7 As shown, a second limit head 15 is provided at the tail of the lock arm 12, and the upper side of the second limit head 15 forms a first contact surface 14 with the thrust shoe 2, and a certain preload ensures that the thrust shoe 2 is in the circumferential direction. There is no relative displacement in the radial direction, there is a sixth gap 17 in the horizontal direction on the left side of the second limiting head 15, there is a seventh gap 16 in the horizontal direction on the right side of the second limiting head 15, and the vertical direction is on the lower left side of the second limiting head 15. There is an eighth gap 18, and there is a ninth gap 19 in the vertical direction on the lower right side of the second limit head 15. By adjusting the height values of the eighth gap 18 and the ninth gap 19, the height of the lock arm 12 of the cantilever beam structure can be adjusted. The preload and the amount of deformation ensure that th...

Embodiment 3

[0035] Such as Figure 8 As shown, a third limit head 24 is provided at the tail of the lock arm 12, and there is a tenth gap 21 between the upper left side of the third limit head 24 and the thrust shoe 2, and the upper right side of the third limit head 24 forms a third gap 21 with the thrust shoe 2. The second contact surface 20, through a certain preload, ensures that there is no relative displacement with the thrust pad 2 in the circumferential and radial directions. There is an eleventh gap 22 in the horizontal direction on the left side of the third limit head 24. The third limit head 24 There is a twelfth gap 23 in the horizontal direction on the right side, there is a thirteenth gap 25 in the vertical direction on the lower left side of the third limiting head 24, and there is a fourteenth gap 26 in the vertical direction on the lower right side of the third limiting head 24. The height values of the thirteenth gap 25 and the fourteenth gap 26 are used to adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com